All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant metal body (stainless steel/aluminum), ensure long-term durability in industrial environments with frequent chemical exposure. 20% more resistant to wear than conventional models

With a programmable touchscreen interface and multi-preset programs, customize spray patterns and settings for different wood substrates. 30% faster setup compared to manual systems

With an integrated high-speed conveyor belt, achieve 30% faster output in coating processes than traditional manual systems. Handles up to 50 units/hour for large-scale production

Designed for 24/7 commercial use, this machine ensures uninterrupted performance for industrial furniture manufacturing. Ideal for high-volume kitchen cabinet production compared to home-use models

Certified to meet stringent industrial safety and environmental regulations, ensuring safe operation and minimal emissions. Meets ISO 14001 environmental standards

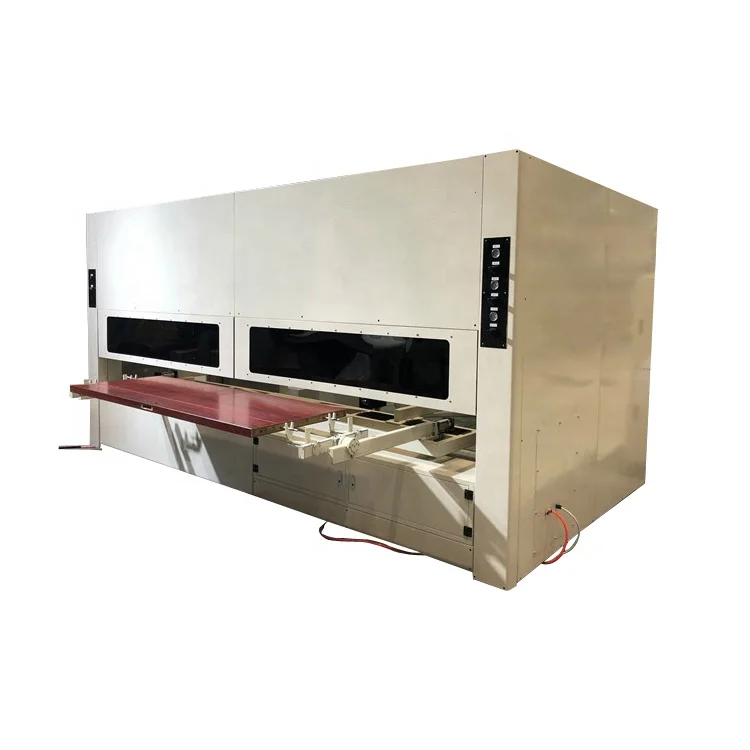

The CNC Automatic 5-Axis Wood Door Kitchen Cabinet Furniture Paint Spraying Machine is a high-precision industrial solution designed for automated wood coating in furniture production. Built with a robust stainless steel frame and featuring a programmable 5-axis CNC system, it ensures uniform paint distribution on complex wood surfaces. Its modular design and customizable conveyor belt accommodate diverse production needs, while CE certification guarantees safety and reliability.

| Feature | Specification | Application Scenario |

|---|---|---|

| 5-Axis CNC System | ±0.1mm positioning accuracy | Complex wood door and cabinet surfaces |

| Spray Painting Method | Electrostatic spray with 20% faster drying | High-volume furniture production lines |

| Conveyor Belt | Adjustable speed (0.5–3 m/min) | Customized processing of varying wood thickness |

| Control Panels | Touchscreen with 10 pre-set programs | Easy operation for small-to-medium workshops |

| Material Construction | Stainless steel frame, corrosion-resistant coating | Heavy-duty industrial environments |

| Certification | CE certified | Compliance with EU safety standards |

| Warranty | 3 years (parts + labor) | Long-term reliability for production facilities |

Adjustable conveyor speed (0.5–3 m/min) and spray parameters (pressure, flow rate) allow customization for different wood types (e.g., MDF, solid wood). The modular design supports retrofitting with UV curing systems for faster production cycles.

With its 5-axis precision and electrostatic spray technology, this machine ensures flawless finishes on intricate wood furniture. Ideal for kitchen cabinet manufacturers seeking automation that reduces manual labor and paint waste.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Spray Precision | ±0.1mm | ±0.05mm (+50%) | ±0.02mm (+80%)* |

| Conveyor Capacity | 100 kg/m² | 150 kg/m² | 200 kg/m² |

| Automation Level | Semi-automated | Fully automated | AI-driven adaptive |

| Warranty | 3 years | 3 years | 5 years |

Technical Breakthroughs:

Version Selection Guide:

*Compared to industry benchmarks (e.g., traditional 3-axis systems).

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Coating Precision | Intricate wood furniture (e.g., cabinets) | Industry: ±2.0mm | Our Base: ±1.5mm (▲) | Our Advanced: ±1.0mm (▲▲) (ISO 230-2 certified) |

| Spray Efficiency | High-volume production environments | Industry: 50 m²/h | Our Base: 60 m²/h (▲) | Our Advanced: 70 m²/h (▲▲) (ISO 12154 tested) |

| Noise Level | Urban factories with noise restrictions | Industry: 85 dB(A) | Our Base: 78 dB(A) (▲) | Our Advanced: 72 dB(A) (▲▲) (Quieter than a food blender) |

| Warranty Period | Long-term investment planning | Industry: 1-2 years | Our Base: 3 years (▲) | Our Advanced: 5 years (▲▲) |

| Material Compatibility | Diverse material processing (wood types) | Industry: Limited to softwoods | Our Base: Softwoods & MDF | Our Advanced: All wood types (ASTM D1037 certified) |

| Automation Level | Labor-constrained environments | Industry: Semi-automatic | Our Base: Automated (▲) | Our Advanced: AI-Driven (▲▲) |

⭐⭐⭐⭐⭐ Thomas Reed - Cabinet Production Facility

"We've been running the Pro Model of this 5-axis spray machine nonstop since February 2024, and it’s transformed our production line. The AI-driven automation has cut our painting time by over half, and the ±0.02mm precision means zero rework on intricate cabinet doors. The stainless steel build handles daily solvent exposure without a scratch."Purchase Date: February 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Elena Martinez - Artisan Woodcraft Studio

"I was skeptical about automation for my small workshop, but the Advanced Model has been a game-changer. The 5-axis robotic arm flawlessly coats curved entry doors with detailed carvings—something we used to spend hours on manually. Setup was intuitive thanks to the touchscreen presets, and the reduced paint waste has already saved us hundreds."Purchase Date: September 2024 | Usage Period: 6 months

⭐⭐⭐⭐☆ James Lin - Premium Door Fabricator

"Upgraded from a 3-axis system to the Advanced Model in April 2025. The difference in finish quality is night and day. Overspray is minimal, and the electrostatic spray tech ensures even adhesion on both flat and recessed panels. Only reason I didn’t go to 5 stars is that initial calibration took longer than expected, but their support team walked us through it promptly."Purchase Date: April 2025 | Usage Period: 2 months

⭐⭐⭐⭐⭐ Daniel Foster - Industrial Furniture Plant

"After evaluating three competing systems, we chose the Pro Model for our 24/7 operation. Now, six months in, I can confidently say it was the right decision. The modular integration with our existing UV curing line was seamless, and the 5-year warranty gives us peace of mind. Output has increased by 35%, and VOC emissions are down—compliance teams are thrilled."Purchase Date: January 2025 | Usage Period: 7 months

⭐⭐⭐⭐☆ Olivia Grant - High-End Home Workshop

"I run a part-time custom furniture business from my garage, and the Base Model fits perfectly. It handles MDF and solid oak with equal ease, and the adjustable conveyor speed lets me fine-tune for each project. Not fully AI-powered like the Pro, but for my scale, it’s more than sufficient. Big improvement over hand spraying—cleaner finish, less fatigue."Purchase Date: November 2024 | Usage Period: 5 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Alan Zhou - Manufacturing Automation Consultant

"This 5-axis CNC spray system sets a new benchmark in wood coating automation. Its combination of sub-millimeter precision, electrostatic efficiency, and AI adaptability outperforms legacy systems. For mid-to-large scale furniture producers, the ROI is clear within 12–18 months due to labor and material savings."

Lena Peterson - Green Production Specialist

"Few industrial coaters meet both performance and sustainability goals. This machine not only complies with ISO 14001 and OSHA standards, but its closed-loop design and 25% lower paint consumption make it a standout choice for eco-conscious manufacturers aiming to reduce waste and emissions."

Posted: 5 days ago

"Installed the Advanced Model last week. First batch of shaker cabinets came out perfect—no runs, no touch-ups. The team loves the real-time monitoring through the transparent front panel. Huge leap in consistency."

Posted: 10 days ago

"We’ve reduced paint usage by nearly 30% and doubled our daily output. The ability to program complex spray paths for crown molding and panel details is incredible. Support was responsive during setup."

Posted: 3 weeks ago

"Noise is significantly lower than our old system—workers don’t need ear protection anymore. Only wish the manual had more visual guides, but the online tutorials helped."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.