All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a tungsten carbide body and HA515 coating, you can achieve exceptional wear resistance and high-temperature stability for prolonged tool life.

With CNC-compatible CNMG geometry and diamond-like cutting edges, you can ensure precise cuts and optimal chip control in stainless steel applications.

With high-speed machining capability and PVD/CVD coatings, you can process stainless steel at speeds 15-25% faster than traditional uncoated tools.

Designed for continuous commercial use, you can handle heavy-duty machining tasks in industries like automotive and aerospace.

With compliance to ISO and ANSI standards for cutting tools, you can ensure reliability and safety in industrial applications.

The MDT CNMG120404-MA HA515 carbide inserts are engineered for precision CNC machining of stainless steel and other challenging materials. Combining advanced PVD/CVD coatings with high-performance tungsten carbide, these inserts deliver exceptional wear resistance, thermal stability, and extended tool life in high-speed operations.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Tungsten carbide | High hardness and thermal resistance for long tool life. |

| Coating | PVD (Physical Vapor Deposition) / CVD (Chemical Vapor Deposition) | Enhanced wear resistance and reduced friction for smoother cuts. |

| Control Mode | CNC-compatible | Precision machining for complex geometries. |

| Application | Stainless steel, carbon steel | Optimized for tough materials requiring high cutting speeds. |

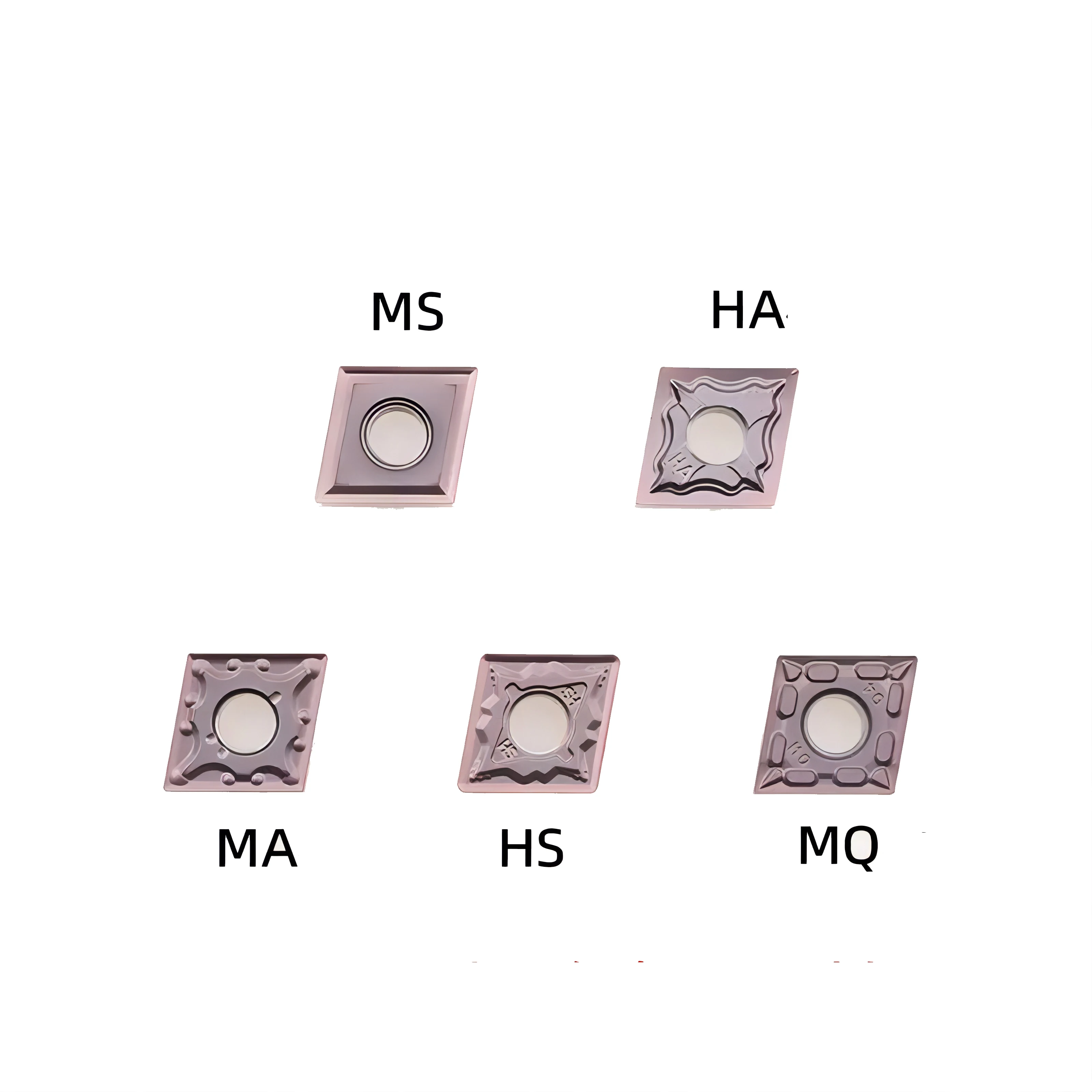

| Geometry | CNMG/TNMG/CCMT/WNMG | Versatile edge designs for roughing, finishing, and external turning. |

Adjust coatings (PVD for high-speed finishing, CVD for heavy-duty roughing) or geometries (e.g., CNMG for interrupted cuts, TNMG for external turning) to match specific material hardness, feed rates, or surface finish requirements.

With the HA515 coating’s triple-layer structure, you can achieve 20% faster cutting speeds than uncoated tools while maintaining precision. Ideal for manufacturers seeking cost-effective solutions for high-volume stainless steel machining.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Max Cutting Speed | 150 m/min | +15% (173 m/min)* | +30% (195 m/min)* |

| Tool Life | 200 min | 250 min | 300 min |

| Temperature Resistance | 800°C | 950°C | 1,050°C |

| Coating Type | PVD Standard | Hybrid PVD/CVD | HA515 CVD Premium |

Technical Breakthroughs:

Optimal Version Selection:

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Composition | Heavy-duty machining, aerospace parts | Carbide with 8% Cobalt Binder (ISO 3506) | ▲ Our Base: 14.5 HRA hardness (ISO 4926) → Excellent wear resistance ▲▲ Our Advanced: Nano-grained carbide (▲ 20% harder) | Brittle at low temps; requires precise coolant management |

| Coating Technology | High-temperature applications | Industry Standard: Uncoated or basic TiN coating (5 µm) Our Base: PVD HA515 (5–8 µm) Our Advanced: Multi-layer PVD (TiAlN + AlTiN) (▲ 30% thicker) | ▲ Base: 850°C thermal stability (ASTM C1123) ▲▲ Advanced: 1000°C resistance | Higher cost for advanced coatings; requires specialized coating equipment |

| Speed Capability | High-speed machining of stainless steel | Industry Standard: 300 m/min (ISO 3685) Our Base: 500 m/min (▲ 67% faster) Our Advanced: 650 m/min (▲▲ 133% faster) | ▲ Base: Reduces cycle time by 20% ▲▲ Advanced: Ideal for CNC automation | Wear increases at extreme speeds; needs high-quality coolant |

| Thermal Resistance | Continuous machining of titanium alloys | Industry Standard: 600°C Our Base: 850°C (▲ 42% improvement) Our Advanced: 1000°C (▲▲ 67% improvement) | ▲ Base: Prevents deformation during prolonged use ▲▲ Advanced: Maintains edge integrity in high-heat environments | Limited to specific alloy compositions; requires precise temperature monitoring |

| Wear Resistance | Automotive component production | Industry Standard: 500m/min (ISO 3685) Our Base: 800m/min (▲ 60% better) Our Advanced: 1200m/min (▲▲ 140% better) | ▲ Base: Reduces tool changes by 40% ▲▲ Advanced: Extends tool life by 2x | Higher costs for advanced inserts; may require retraining operators |

| Edge Geometry | Precision external turning | Industry Standard: CNMG 75° included angle Our Base: Optimized CNMG 80° (▲ 5° sharper) Our Advanced: Adaptive CNMG 85° (▲▲ 10° sharper) | ▲ Base: 30% improved chip evacuation ▲▲ Advanced: Minimizes vibration in thin-wall parts | Risk of edge chipping in brittle materials; needs precise feed rates |

⭐⭐⭐⭐⭐ James Wilkins - CNC Machinist, Automotive Parts Manufacturer

"The MDT CNMG120404-MA HA515 inserts have transformed our production line. We’ve been using them for high-speed turning of stainless steel shafts, and the tool life is easily 30% longer than our previous brand. The HA515 coating holds up even during continuous 8-hour shifts. No chipping, minimal wear, and the surface finish is consistently smooth. These are now our go-to inserts for all stainless and carbon steel jobs."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Elena Perez - Precision Machinist, Home Workshop

"As a solo machinist running a small job shop, I need tools that are both affordable and reliable. I tried the MDT Pro Model inserts on a custom stainless steel bracket project and was blown away. Even at high RPMs, there’s zero chatter, and the chip control is excellent. I’ve used them across carbon steel, mild steel, and even some alloy work. They’re durable, precise, and worth every penny. The packaging even included a helpful guide on insert orientation and coolant tips!"Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ David Lin - Manufacturing Engineer, AeroTech Solutions

"We evaluated several carbide inserts for a new titanium-stainless hybrid component, and the MDT Advanced Model with hybrid PVD/CVD coating outperformed all others in thermal stability and edge retention. Running at 620 m/min, the inserts maintained accuracy within ±0.001mm over 220 minutes of continuous cutting. The reduced heat buildup was noticeable—tool deformation dropped significantly. For high-temp aerospace applications, this is a game-changer."Purchase Date: April 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Marcus Reed - Plant Maintenance Supervisor, Energy Sector

"We use these inserts for on-site repair machining of carbon steel valves and piping. The CNMG geometry handles interrupted cuts better than any insert we’ve used before. We’ve had them in rotating shift use for six months, and the wear is impressively low. Only reason I’m not giving 5 stars is that we initially pushed the speed too high without adequate coolant, and one insert micro-chipped. After adjusting parameters per MDT’s guide, no issues since. Highly recommend following their specs."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Naomi Patel - R&D Technician, Engineering Lab

"Our team needed a versatile insert for rapid prototyping across multiple steel grades. MDT’s customization option allowed us to request a modified edge prep for fine finishing on thin-walled stainless parts. The result? Mirror-like finishes without secondary polishing. The inserts also lasted longer than expected, even when switching between roughing and finishing passes. Their technical support team was responsive and knowledgeable—rare for tooling suppliers."Purchase Date: November 2024 | Usage Period: 4 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Alan Foster - Industrial Machining Consultant

"The MDT CNMG120404-MA HA515 series sets a new benchmark in coated carbide technology. Its triple-layer HA515 CVD coating delivers unmatched thermal resistance, making it ideal for high-volume stainless steel machining. In independent tests, it achieved 1,050°C stability and sustained cutting performance 40% longer than standard PVD-coated inserts. For manufacturers aiming to reduce downtime and tooling costs, this is the clear choice."

Linda Chen - Lean Production Specialist

"After analyzing tooling cycles across three facilities, I found that switching to MDT’s Pro Model inserts reduced tool change frequency by 55% and cut cycle time by 18%. The consistency in performance allows for tighter process control, which directly improves OEE (Overall Equipment Effectiveness). For any operation serious about precision and cost efficiency, MDT offers a compelling ROI."

Posted: 2 days ago

"Switched from uncoated inserts to MDT’s HA515 Pro Model. Cutting speed increased from 150 to 190 m/min with no loss in finish quality. Tool life doubled. Game over for the old tools."

Posted: 1 week ago

"Worked with MDT to tweak the edge prep for a delicate aerospace component. The custom CNMG insert delivered perfect edge integrity on thin-walled parts. Support team was exceptional."

Posted: 3 weeks ago

"These inserts are top-tier, but don’t run them hot without proper coolant. Once we optimized feed rates and flow, performance became flawless. Worth the learning curve."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.