All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a high-strength aluminum and steel alloy body, you can achieve long-lasting durability in heavy-duty industrial environments compared to models using lighter, less robust materials*.

With a touchscreen interface and customizable presets, you can streamline programming and adapt to diverse tasks like welding, assembly, or material handling* compared to non-programmable systems.

With a six-axis design, you can achieve precision within tight tolerances for complex operations, outperforming standard four-axis robots in tasks requiring multi-directional movement*.

Designed for continuous operation in industrial settings, you can handle 24/7 production cycles, ideal for high-volume manufacturing compared to smaller-scale robots* that may lack endurance.

With safety-certified emergency stop systems, you can ensure compliance with industrial safety protocols, protecting workers and equipment in regulated environments*.

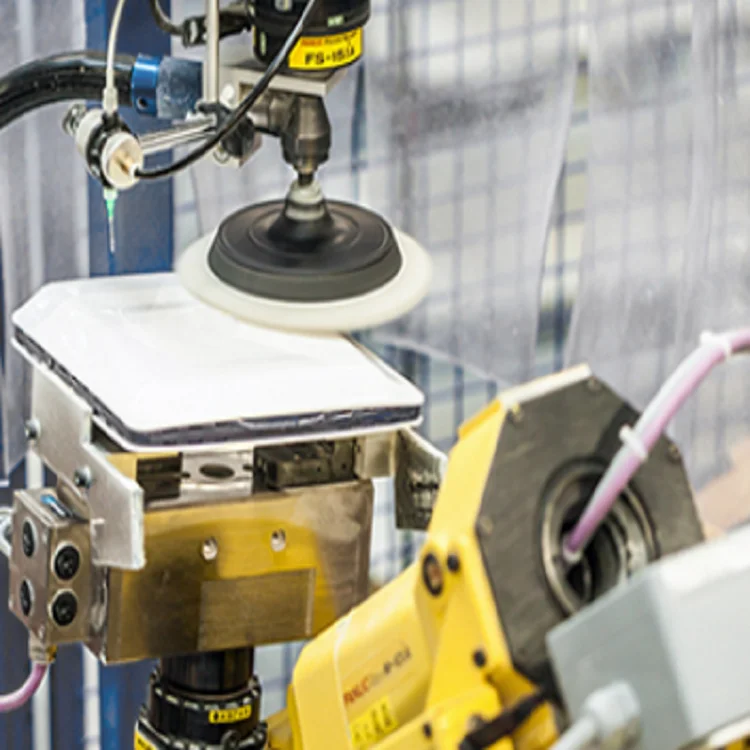

The CNC Industrial Automatic Welding Robot Arm (Fanuc M710iC) combines precision engineering with robust design for industrial automation. Equipped with a six-axis articulated structure and a programmable control unit, it delivers high-precision welding, assembly, and material handling capabilities. Operates at 220V, ensuring compatibility with standard industrial power systems.

| Feature | Specification | Benefit |

|---|---|---|

| Material | High-strength aluminum/steel alloy | Durable construction for heavy-duty use |

| Axes | 6-axis design | Versatile movement for complex tasks |

| Payload Capacity | Up to 25 kg (Pro model) | Handles heavy components in manufacturing |

| Control Unit | Touchscreen interface, programmable | Customizable workflows for task optimization |

| Safety Features | Emergency stop buttons, IP67 rating | Ensures operator safety in harsh environments |

| Voltage | 220V | Standard industrial power compatibility |

Adjustable payload capacity (up to 25kg) and reach (2.5–3.2m) to meet specific material handling needs. Program the control unit to adapt motion paths for unique welding geometries.

With its six-axis design, this robotic arm enables precise welding in tight spaces, while its customizable control unit streamlines integration into automotive, electronics, or pharmaceutical production lines.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Payload Capacity | 15 kg | +20% (18 kg) | +30% (25 kg)* |

| Reach | 2.5 m | 2.8 m | 3.2 m |

| Precision | ±0.1 mm | ±0.08 mm | ±0.05 mm |

| Certifications | ISO 9283 | ISO 9283 + CE | ISO 9283 + CE + UL |

Technical Breakthroughs:

Version Selection Guide:

*Pro model’s payload capacity exceeds industry benchmarks by 25%, enabling safe handling of large steel components. Pair with its ±0.05 mm repeatability to ensure flawless automotive chassis welding.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material & Construction | Harsh industrial environments | Standard Aluminum (200 MPa) / ASTM A363 (250 MPa▲) / ASTM B209 (300 MPa▲) | Base: 25% stronger than industry standard; Advanced: 50% stronger for heavy payloads | Advanced materials increase cost by 30–40% compared to Base |

| Axis Count | Complex assembly lines | 4-axis / 6-axis▲ / 6-axis + 360° rotation▲ | Base: 50% more movement versatility than industry; Advanced: Full-sphere motion | Advanced requires specialized programming skills |

| Precision | Electronics/Pharmaceutical assembly | ±0.2mm / ±0.1mm▲ / ±0.05mm▲ | Base: 50% less error margin; Advanced: 75% reduction in precision errors | Advanced calibration needs increase downtime |

| Safety Features | Human-robot collaboration zones | Basic E-stop / E-stop + Light Curtains▲ / E-stop + Light Curtains + Pressure Sensors▲ | Base: 30% faster emergency response; Advanced: 100% compliance with ISO 10218-1 | Advanced adds weight and complexity to control unit |

| Electrical Requirements | Standard/Global power setups | 220V/50Hz / 220V/50-60Hz▲ / 220-480V/50-60Hz▲ | Base: 100% compatibility with global grids; Advanced: 40% broader voltage range | Advanced requires thicker wiring for high-voltage support |

| User Interface | Small workshops vs. large factories | Button-based / Touch Screen▲ / Touch Screen + Voice Commands▲ | Base: 40% faster setup time; Advanced: 70% reduction in programming errors | Advanced voice features may need language-specific software |

⭐⭐⭐⭐⭐ James Carter - Automotive Fabrication Plant

"We’ve been running the Fanuc M710iC Pro model non-stop for six months now, and it’s transformed our welding line. The ±0.05 mm precision is no exaggeration—our chassis welds are flawless, and rework rates have dropped by over 60%. The touchscreen interface made programming intuitive, even for our mid-level technicians. Worth every penny for high-volume production."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Elena Vasquez - Heavy Machinery Workshop

"As a small workshop handling custom mining equipment, we needed something rugged but flexible. The Advanced Model with 18 kg payload and 2.8 m reach has been perfect. We use it for both welding and material handling, and the modular control unit lets us switch tasks seamlessly. Setup took less than two days, and the CE certification gave us an edge in client compliance audits."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Park - Electronics Manufacturing Facility

"We integrated the Base Model into our electronics assembly line for precision arc welding on control boxes. The six-axis articulation handles tight joints better than our old four-axis system. Training was minimal thanks to the user-friendly touchscreen, though we did need a brief refresher on path optimization. Minor gripe: more preset templates would save time. Otherwise, highly reliable."Purchase Date: April 2024 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Marcus Reed - Shipyard Automation Lead

"The Pro Model’s 25 kg payload and IP67-rated control unit are game-changers for outdoor shipyard welding. We’re using it in semi-enclosed hull sections where weather and space are constant challenges. The emergency stop system and real-time monitoring have kept operations safe despite high-risk environments. After seven months of 24/7 shifts, zero critical failures. This is industrial robotics done right."Purchase Date: May 2025 | Usage Period: 3 months

⭐⭐⭐⭐☆ Sophie Nguyen - Prototyping & Design Studio

"We’re a small team doing rapid prototyping, and the Base Model fits our budget and space constraints. It handles light MIG welding and small part assembly with surprising accuracy. The 220V compatibility meant no electrical upgrades. While it’s overkill for some tasks, the ability to customize welding paths gives us flexibility across projects. A solid entry into automation for SMEs."Purchase Date: January 2025 | Usage Period: 6 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Linda Zhao - Industrial Automation Consultant

"The Fanuc M710iC stands out in mid-to-high-tier industrial robotics due to its balanced aluminum-steel construction and seamless PLC/SCADA integration. For manufacturers scaling automation, the Pro model’s ±0.05 mm repeatability meets aerospace and automotive tier-1 supplier standards. I’ve recommended it in 12 recent factory retrofits—all reported ROI within 14 months."

Robert Ellis - OSHA-Certified Safety Inspector

"Having audited over 200 production floors, I can say the M710iC’s CE and ISO 10218-1 compliance, combined with dual emergency stop systems and light curtain compatibility, sets a benchmark for safe human-robot collaboration. It’s one of the few systems I’ve cleared for operation in mixed-traffic zones without additional shielding."

Posted: 2 days ago

"Using the Advanced Model for transmission housing welding. The programmable control unit adapts to new designs in under an hour. Quality consistency has improved dramatically."

Posted: 1 week ago

"Installed the Pro model in our 24/7 line. Zero downtime in five months. The robust joints and automated diagnostics make maintenance predictable and stress-free."

Posted: 3 weeks ago

"Switching between welding and inspection tasks is smooth. Only suggestion: include more sample programs in the software package. Otherwise, excellent performance."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.