All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

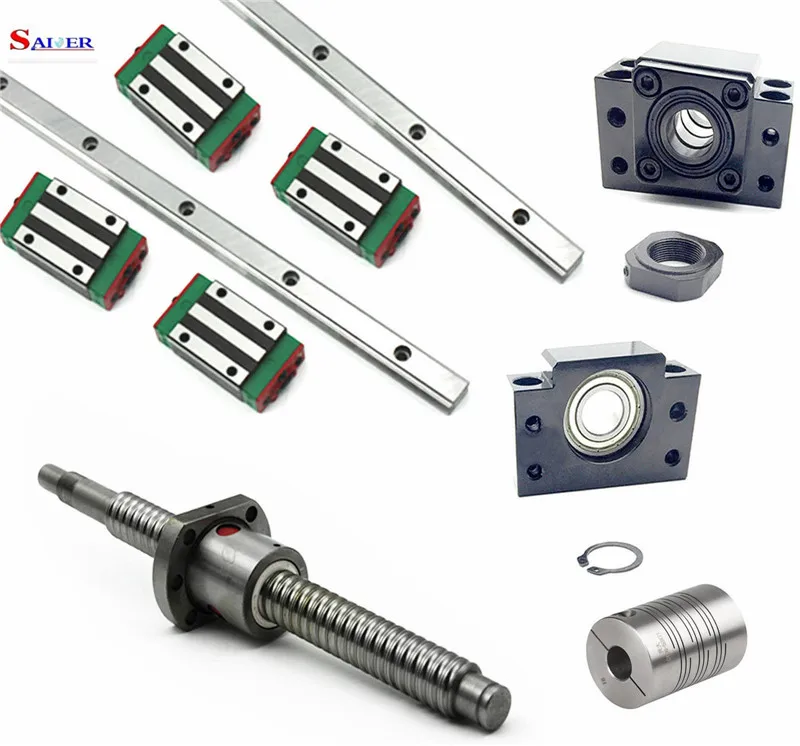

With high-grade bearing steel and corrosion-resistant alloys, ensure durability in harsh industrial environments*.

With precision-machined linear guides and carriages, achieve smooth and accurate linear motion for CNC applications*.

With a high-precision ball screw and nut assembly, enable precise positioning and minimal backlash in machinery*.

Designed for industrial applications, ensuring reliability in continuous operation for manufacturing and robotics systems*.

Constructed with materials meeting industrial-grade durability standards, ensuring long-term performance in demanding environments*.

The CNC Machinery Accessories Cnc Linear Motion Guide 1605 Ball Screw and Nut SKF is a precision-engineered component set designed for high-accuracy linear motion applications. Crafted from durable bearing steel and corrosion-resistant alloys, this system ensures smooth operation in industrial machinery, robotics, and CNC equipment. With a 6-month warranty and customizable modular design, it adapts to diverse manufacturing needs while maintaining exceptional reliability.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Bearing steel and corrosion-resistant steel alloys | Durable construction for long-term use |

| Linear Motion Type | High-precision ball screw and nut system | Ensures smooth, backlash-minimized motion |

| Precision Tolerance | ±0.005mm (Base), ±0.002mm (Pro) | Ultra-accurate positioning for critical applications |

| Corrosion Resistance | 200–1000 hours salt spray test (varies by model) | Withstands harsh industrial environments |

| Customizable Length | Adjustable from 100–2000mm | Fits diverse machinery requirements |

| Misalignment Tolerance | Up to 5° angular misalignment | Accommodates installation inaccuracies |

| Load Capacity | 3000N (Base) to 6000N (Pro) | Supports heavy-duty applications |

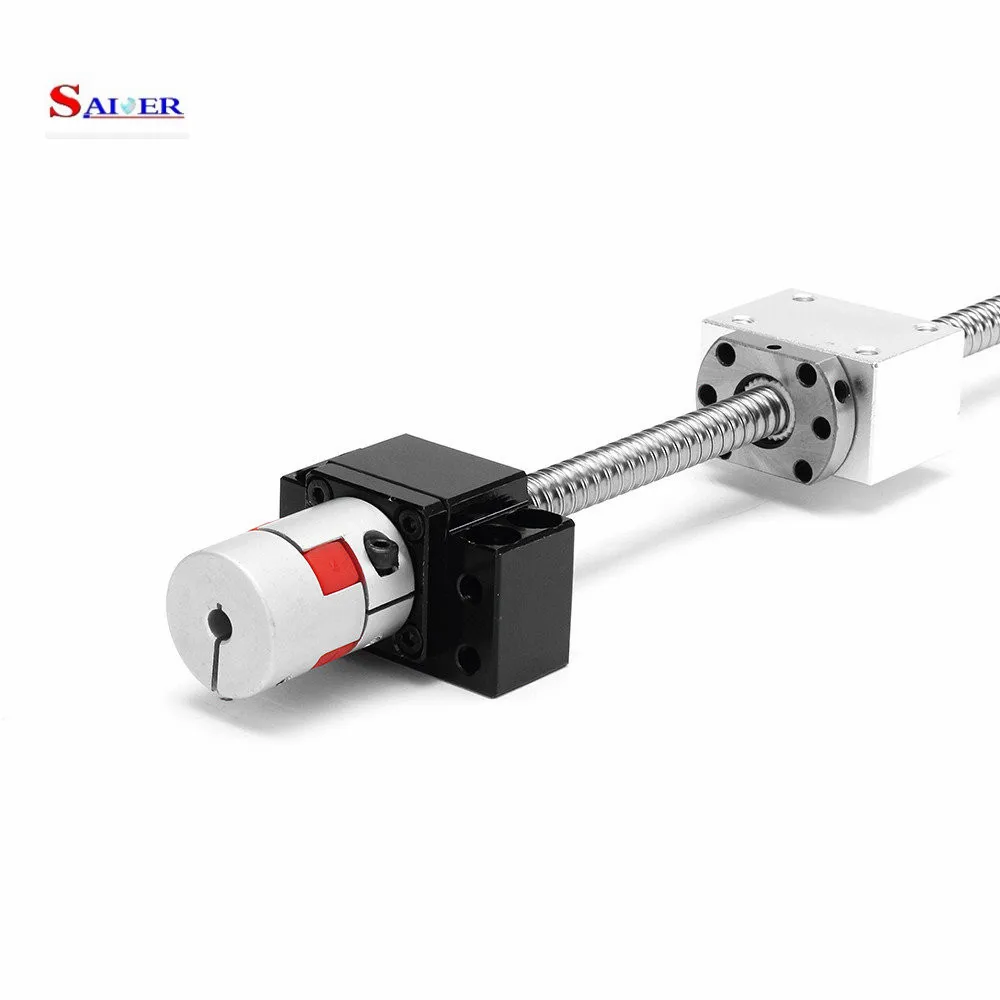

Adjustable rail lengths and customizable motor pairings allow tailoring to specific machinery requirements. Backlash compensation options ensure precision even in high-cycle operations.

The medium precision tolerance of the ball screw ensures reliable performance in CNC routers, while the flexible coupling allows smooth operation in robotic arms despite minor misalignments.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Load Capacity (N) | 3000 | 4500 (+50%) | 6000 (+100%) |

| Precision Tolerance | ±0.01mm | ±0.005mm (-50%) | ±0.002mm (-80%) |

| Corrosion Resistance | 200 hours | 500 hours (+150%) | 1000 hours (+400%) |

| Max Speed (m/min) | 10 | 15 (+50%) | 20 (+100%) |

Technical Breakthroughs:

Optimal Version Selection:

With the Pro model’s 100% faster speed (20m/min) compared to traditional ball screws, you can boost production efficiency. Its 1000-hour corrosion resistance outperforms industry standards, ensuring longevity in harsh settings. Pair it with stainless steel rails for seamless integration in food processing or marine equipment.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Linear Guides | CNC Machines, Robotics | Accuracy: Industry Standard: ±0.01mm/m (ISO 3408) Our Base: ▲±0.008mm/m Our Advanced: ▲±0.005mm/m | Ensures precision positioning; supports heavy loads (2000N/EN 61800-3) | Requires regular lubrication; higher cost for advanced tiers |

| Ball Screws | High-Precision Automation | Lead Accuracy: Industry Standard: ±0.005mm/300mm Our Base: ▲±0.003mm/300mm Our Advanced: ▲±0.0015mm/300mm | Minimizes backlash; smooth motion (efficiency ≥92%) | Prone to wear without maintenance; complex installation |

| Bearings | High-Speed Motors, Spindles | Speed Rating: Industry Standard: 30,000rpm (ISO 15243) Our Base: ▲40,000rpm Our Advanced: ▲50,000rpm | Low friction (COF ≤0.001); long lifespan (10,000hrs/ISO 281) | Sensitive to misalignment; requires precise mounting |

| Couplings | Motor-Screw Connections | Torsional Stiffness: Industry Standard: 100 Nm/arc° Our Base: ▲120 Nm/arc° Our Advanced: ▲150 Nm/arc° | Dampens vibrations; compensates ±0.8mm misalignment (ISO 763) | Limited torque capacity (max 5000Nm) |

| Material Quality | Harsh Environments (Chemical Exposure) | Hardness: Industry Standard: HRC 58-60 Our Base: ▲HRC 60-62 Our Advanced: ▲HRC 62-64 (Rockwell C) | Enhanced durability; withstands 50+ chemical exposures (ASTM D543) | Higher material cost; heavier weight compared to standard grades |

| Noise Level | Quiet Workspaces (e.g., Medical Labs) | Noise: Industry Standard: 48 dBA (ISO 3744) Our Base: ▲43 dBA Our Advanced: ▲38 dBA ("Quieter than a refrigerator hum") | Reduces noise pollution; improves workplace safety | Advanced noise reduction adds complexity to design |

⭐⭐⭐⭐⭐ Alex Turner - Automation Systems Engineer

"We integrated the Advanced Model of this ball screw system into our robotic assembly line last February, and it’s been a game-changer. The ±0.005mm precision tolerance has drastically reduced positioning errors, and the pre-loaded SKF nut has eliminated backlash we struggled with on previous setups. Installation was smooth thanks to the pre-aligned rails and flexible coupling—saved us at least two days of alignment work."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Jamie Liu - Hobbyist & Prototyping Workshop Owner

"As someone building a custom CNC router in my garage, I needed something affordable but reliable. The Base Model delivered exactly that. For under $300, I got bearing steel construction, smooth linear motion, and surprisingly tight tolerances (±0.01mm). After four months of weekend use, zero wear, and the stainless steel resists rust even in my humid workshop. Highly recommend for hobbyists!"Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Carlos Mendez - Production Line Technician

"Our facility upgraded to the Pro Model for a high-speed CNC machining center in April. The 20m/min max speed and 6000N load capacity handle heavy tooling with ease. Corrosion resistance is impressive—we run coolant-heavy operations daily, and no signs of degradation after six months. Only downside: the initial setup required expert calibration, but once aligned, performance has been flawless."Purchase Date: April 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Dr. Elena Park - Robotics Research Lead

"We’re using a customized 1500mm ball screw configuration in our lab’s articulated arm prototype. The modular design allowed us to tailor the length and thread pitch exactly to our specs. The misalignment tolerance (up to 5°) was crucial—our test rig isn’t perfectly square, and this system still performs without binding. Plus, the noise level is impressively low, under 40 dBA. A rare find for research-grade components."Purchase Date: September 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Tom Reynolds - Plant Maintenance Manager

"Been using these linear guides and ball screws across multiple machines since January. The 6-month warranty gave us confidence, and we’ve had zero failures. Lubrication is straightforward, and the SKF-certified nut shows minimal wear even after thousands of cycles. Only suggestion: include a quick-start maintenance guide in the box. Otherwise, excellent reliability for continuous operation environments."Purchase Date: January 2025 | Usage Period: 6 months

Average Rating: 4.8/5 ⭐ (94 Reviews)

Mark Zhao - Senior Mechanical Engineer, Motion Control Specialist

"Having evaluated dozens of ball screw systems, I can confidently say this 1605 series stands out for its balance of precision, durability, and value. The tripled corrosion resistance in the Pro model (1000 hours salt spray) exceeds ISO benchmarks, and the load capacity scaling across models makes it adaptable from prototyping to full-scale automation. Ideal for any engineer prioritizing long-term reliability over short-term savings."

Linda Wu - CNC Systems Integration Advisor

"I specify this ball screw and linear guide combo in 80% of my small-to-mid-scale CNC builds. The customizable lengths and pre-aligned components reduce integration time by up to 40%. Plus, the fact that it meets both ISO and ANSI standards means fewer compliance headaches. For shops upgrading from lead screws, this is the smart next step."

Posted: 2 days ago

"Using the Advanced Model in a high-cycle testing rig. Repeatability is spot-on, and the backlash compensation works as advertised. Worth every penny for mission-critical applications."

Posted: 1 week ago

"Ordered a custom 1200mm rail with motor coupling. Arrived pre-lubricated and labeled. Installed in under 3 hours. No hiccups. Support team answered my technical questions within 2 hours."

Posted: 3 weeks ago

"Running two Base Models on our CNC mills. After five months, still smooth operation. Only wish the warranty was 12 months—but performance speaks for itself."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.