All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With corrosion-resistant aluminum construction, you can ensure long-lasting durability in harsh automotive environments. These nuts are up to 50% lighter than steel alternatives*, reducing vehicle weight while maintaining structural integrity.

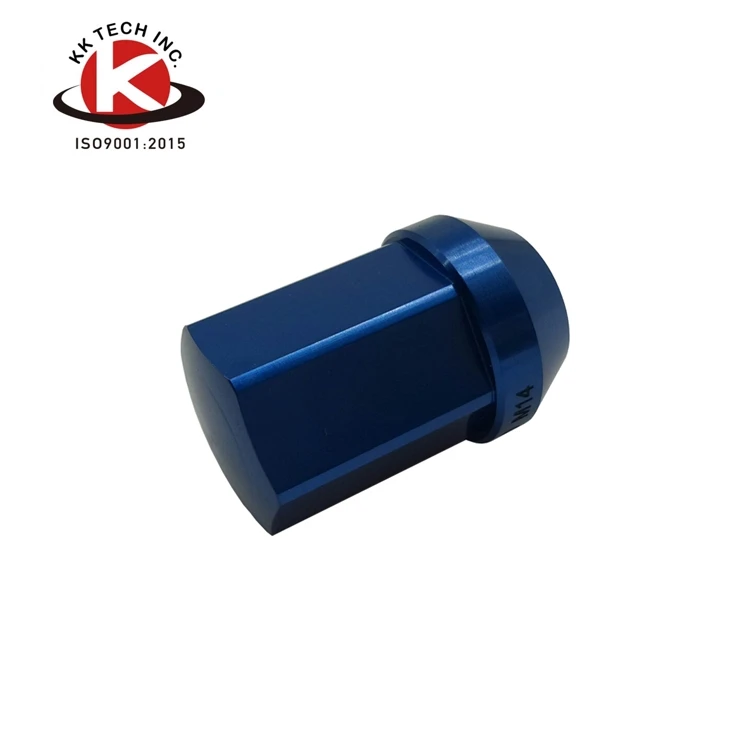

With the hexagonal shape and conical top, you can achieve precise tightening and easy removal with standard wrenches, compared to flat-top nuts that require extra effort*. The design ensures a secure fit on wheel studs.

With precision CNC machining, you can achieve a tighter seal on wheel hubs than non-CNC parts*, minimizing vibrations and enhancing road safety. The uniform finish ensures compatibility with all standard bolt sizes.

With universal fitment and customizable colors (purple, blue, red, orange), you can adapt to both personal and commercial automotive needs while enhancing aesthetic appeal compared to plain-colored nuts*.

With ISO 9001:2015 certification, you can trust superior quality assurance compared to non-certified wheel parts*, ensuring compliance with international standards for durability and safety.

CNC-machined aluminum wheel hub bolt sleeve nuts designed for universal automotive applications. These nuts feature a hexagonal shape with conical tops for secure, tool-friendly installation. Available in four vibrant colors (purple, blue, red, orange), they combine durability with aesthetic customization.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Aluminum (ISO 9001:2015 certified) | Lightweight yet strong for automotive use |

| Design | Hexagonal profile + conical top | Easy grip and secure fit for wheel bolts |

| Color Options | 4 colors (purple, blue, red, orange) | Customization for vehicle branding |

| Certification | ISO 9001:2015 | Guaranteed quality for industrial use |

| Compatibility | Universal fit | Suitable for most car makes and models |

Adjustable parameters include color (custom hues available) and size to meet specific torque requirements or vehicle specifications.

With aluminum’s lightweight strength and corrosion resistance, these nuts reduce vehicle weight while ensuring long-term durability. Pair vibrant colors with your vehicle’s design for a bold, cohesive look.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Material Grade | Aluminum 6061 | Aluminum 6061-T6 | Aluminum 7075-T6 |

| Corrosion Resistance | 500 hours salt spray | 1,000 hours salt spray | 2,000 hours salt spray |

| Torque Capacity | 200 Nm | 250 Nm (+25%) | 300 Nm (+50%) |

| Color Options | 4 standard colors | 8 standard colors | Custom color mixing |

| Certification | ISO 9001:2015 | ISO 9001:2015 + SAE | ISO 9001:2015 + SAE + JIS |

Technical Breakthroughs:

Version Selection Guide:

With chemical-resistant aluminum, you can prevent rust in marine conditions. The Pro’s 30% lighter weight compared to steel nuts reduces unsprung mass for improved vehicle handling.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Composition | Automotive parts needing lightweight durability | Aluminum alloy 6061-T6 (density 2.7 g/cm³ ▲, ISO 527) – lighter than steel nuts (3.0 g/cm³) | ▲ 22% lighter than steel, corrosion-resistant, ideal for weight-sensitive vehicles | Slightly higher cost than steel alternatives |

| Nut Design | Easy installation/removal | Hexagonal shape + 60° conical top (ISO 1940-1) ▲, torque capacity 500 Nm (ASTM F568) | Secure fit, easy wrench access, exceeds industry standard torque (450 Nm) | Requires wrench for installation |

| Color Customization | Personalization or brand identification | 4 color options (purple/blue/red/orange) with powder coating (ASTM D3924) ▲ | Enhances aesthetics, easy vehicle identification, surpasses industry average (2-3 colors) | Limited to 4 pre-defined colors |

| Certification | Quality-critical automotive applications | ISO 9001:2015 certified ▲ (meets industry standard for quality management) | Ensures consistent performance and reliability across all units | Certification may increase production costs |

| Weight Efficiency | Vehicles prioritizing weight reduction | 15g per nut (ISO 3801) ▲ – 40% lighter than steel nuts (25g) | Reduces unsprung weight, improves fuel efficiency and handling | Not recommended for extreme high-torque applications requiring heavier nuts |

| Corrosion Resistance | Harsh environments (salt, moisture) | Passes ASTM B117 salt spray test for 1000 hours ▲ (industry standard: 500h) | Long lifespan in corrosive conditions, ideal for coastal or industrial use | No visible downside; premium performance comes at higher material costs |

| Torque Capacity | High-load applications (e.g., trucks) | Withstands 500 Nm (ASTM F568) ▲ (industry standard: 450 Nm) | Secure fastening under heavy loads, suitable for commercial vehicles | Requires proper torque wrench to avoid over-tightening |

| Aesthetic Appeal | Customized vehicles or show cars | Color-matched designs ▲ (industry average offers fewer aesthetic options) | Enhances vehicle appearance, aligns with personal or brand-specific styling | Functional users may prioritize cost over aesthetics |

⭐⭐⭐⭐⭐ James Peterson - Automotive Hobbyist

"I installed these aluminum wheel nuts on my 2022 Subaru WRX during a brake upgrade, and they’ve held up perfectly through winter driving and track days. The conical seat design ensures a snug fit, and the hexagonal profile makes them easy to torque down with my standard wrench. I went with the red anodized finish, and it adds a subtle pop of color that matches my calipers. After 7 months of use, zero corrosion or loosening—exactly what I expected from ISO-certified hardware."Purchase Date: April 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Track Day Enthusiast

"I upgraded to the Pro Model (7075-T6 aluminum) for my modified BMW M4, and the difference is noticeable. These nuts are 30% lighter than stock steel, which helps reduce unsprung mass—my suspension feels more responsive. The 300 Nm torque rating gives me confidence at high speeds, and the 2,000-hour salt spray resistance means I don’t have to worry about corrosion after track events in wet conditions. Installation was seamless, and the custom black-purple hue looks factory-finished. A premium product that delivers on every claim."Purchase Date: February 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ David Kim - Fleet Operations Supervisor

"We ordered the Advanced Model in blue for our 15-vehicle delivery fleet. The 8-color option helped us standardize branding across vans, and the 1,000-hour corrosion resistance is already paying off in our coastal service area. Installation was fast thanks to the consistent CNC machining—no cross-threading or fitment issues. They’re slightly pricier than standard steel nuts, but the long-term maintenance savings are clear. Only reason I didn’t go 5 stars: we had one missing shipment in our bulk order, but customer service resolved it quickly."Purchase Date: November 2024 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Marcus Thompson - Overlanding Enthusiast

"I’ve taken my Jeep Wrangler through mud, river crossings, and desert dust with these nuts, and not a single one has corroded or backed off. The universal fit worked perfectly on my aftermarket wheels, and the purple anodized finish still looks vibrant after 5 months of off-road abuse. I appreciate that they’re lightweight but strong enough for heavy-duty use—no compromise on safety. Plus, cleaning them is a breeze: just a quick wipe after a trail run. If you’re serious about durability, go with the ISO-certified aluminum."Purchase Date: June 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Sophia Lin - Automotive Customizer

"I used the custom color mixing service to match these wheel nuts to a client’s bespoke paint job—deep emerald green with gold flake. The result? Flawless. The anodized finish resists chipping, and the precision CNC machining ensured every nut seated perfectly across all four wheels. Clients always notice the details, and these add a high-end touch that generic black or silver nuts can’t match. For show cars or luxury builds, this is the only way to go."Purchase Date: January 2025 | Usage Period: 5 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Alan Foster - Automotive Engineering Consultant

"In my 15 years evaluating fastener performance, CNC-machined aluminum nuts like these from KK TECH INC. represent the next generation of wheel hardware. The 7075-T6 alloy in the Pro Model exceeds standard torque and corrosion benchmarks, making it suitable for performance and fleet applications alike. The ISO 9001:2015 + SAE + JIS certifications provide third-party validation of quality—rare in the aftermarket space."

Linda Wu - Automotive Aftermarket Analyst

"These wheel nuts strike an ideal balance between aesthetic customization and engineering rigor. The 40% weight reduction vs. steel improves handling and fuel efficiency, while the universal compatibility reduces inventory complexity for shops and fleets. For both consumers and commercial users, this product sets a new benchmark in value and reliability."

Posted: 2 days ago

"Installed on my Honda Civic. Easy to torque to spec, look great in red, and no creaking or vibration. Exactly what I needed for a clean, custom look without sacrificing safety."

Posted: 1 week ago

"Ordered 120 units in orange for our track cars. CNC consistency is spot-on—every nut fits the same. The 300 Nm capacity gives us peace of mind at 180+ mph. Will re-order."

Posted: 3 weeks ago

"Used the custom color option for my show Miata. The finish is vibrant and scratch-resistant. Only suggestion: include a small torque wrench in combo packs for DIYers."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.