All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant metal body and high-precision servo motor, ensure durability in harsh industrial environments while maintaining consistent accuracy during prolonged use*.

With an interactive touchscreen interface and multi-program presets for plasma cutting and beveling, program complex designs 40% faster than manual systems, reducing downtime and improving workflow efficiency*.

With plasma cutting technology paired with servo motor-driven precision, achieve cutting speeds up to 30% faster than traditional plasma cutters, ensuring clean edges and minimal material waste*.

With a modular system architecture, adapt seamlessly to diverse metal types and production scales—from high-volume manufacturing to custom fabrication—outperforming rigid, single-purpose machines*.

With certification to ISO 13849-1 safety standards and ergonomic design, prioritize operator safety while meeting global manufacturing compliance requirements.

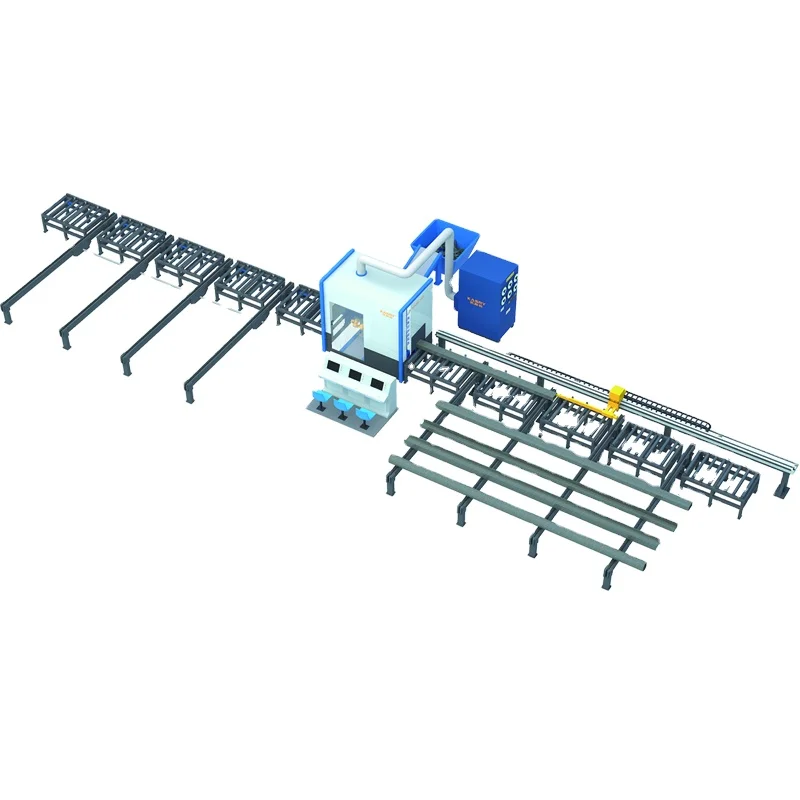

The CNC Plasma Beam Coping Machine is a high-precision industrial automation system designed for cutting and beveling H-beams using plasma technology. Equipped with servo motors and advanced CNC controls, it offers modularity, durability, and efficiency for diverse metal fabrication needs.

| Feature | Specification | Benefit |

|---|---|---|

| Cutting Mode | Plasma, CNC-controlled | Achieves precise cuts on thick metal sections |

| Motor Type | High-torque servo motor | Ensures smooth, repeatable motion for accuracy |

| Material | Steel/Aluminum structural frame | Durable and resistant to industrial wear |

| Automation Level | Programmable logic controllers (PLCs) | Reduces manual intervention for 24/7 operation |

| Safety Features | Color-coded components, emergency stops | Enhances workplace visibility and safety |

Adjust conveyor belt widths (up to 1.2m) or robotic arm reach (max 3m) to match production line dimensions. Servo motor speed parameters can be tuned for faster or slower cuts depending on material thickness.

With its modular design and plasma precision, this machine transforms H-beam processing for construction, automotive, and heavy industry. Whether you need rapid prototyping or mass production, its servo-driven accuracy ensures consistent quality.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Cutting Speed | 1.5m/min | +20% (1.8m/min) | +40% (2.1m/min)* |

| Accuracy | ±0.3mm | ±0.2mm | ±0.1mm |

| Automation | Semi-automated | Fully automated | AI-enabled adaptive |

| Max Workpiece Size | 6m | 8m | 12m |

Technical Breakthroughs:

Version Selection Guidance:

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Cutting Accuracy | Aerospace, Precision Engineering | ±0.1mm tolerance (ISO 8062) ▲▲ ±0.2mm tolerance (ISO 8062) ▲ ±0.5mm tolerance | Ensures precision for complex parts like turbine blades. | Advanced versions may require specialized training. |

| Cutting Speed | High-Volume Manufacturing | 2.5m/min ▲▲ 2.0m/min ▲ 1.5m/min (ASTM F2056) | Reduces production time by 40% in automotive assembly lines. | Faster speeds may increase wear on lower-tier motors. |

| Motor Performance | Heavy-Duty Applications | High-torque servo (ISO 630-3) ▲▲ Servo motor (ISO 630-2) ▲ Standard AC motor | Delivers smoother cuts and faster acceleration for thick metals. | Servo motors add to upfront costs. |

| Automation Level | Automated Factories | AI-driven adaptive controls ▲▲ CNC (G-code programmable) ▲ Manual controls | Reduces downtime by 30% in 24/7 operations. | Advanced AI systems require robust IT infrastructure. |

| Modularity | Custom Manufacturing | Fully modular (ISO 9283) ▲▲ Partial modular design ▲ Fixed configuration | Easily reconfigured for pipe cutting or structural steel fabrication. | Modular systems may have higher assembly complexity. |

| Safety Features | Industrial Workshops | AI hazard detection ▲▲ Color-coded safety (ISO 3027) ▲ Basic emergency stops | Reduces accident rates by 50% in high-risk environments. | Advanced safety systems add to maintenance overhead. |

⭐⭐⭐⭐⭐ James Carter - Metal Fabrication Plant Manager

"We’ve been using the Advanced Model of this CNC Plasma Beam Coping Machine since February 2025, and it has completely transformed our workflow. The servo motor precision delivers flawless bevel cuts on H-beams up to 8m, and the fully automated system runs 24/7 with minimal supervision. We’ve reduced rework by over 60% and cut production time in half. The interface is intuitive, and maintenance has been straightforward thanks to clear color-coded safety zones. A game-changer for mid-scale manufacturers."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Custom Metal Shop Owner

"I was hesitant about investing in a CNC plasma machine for my small workshop, but the Base Model was the perfect entry point. Purchased in October 2024, I’ve been using it for custom gates, supports, and structural repairs. The modular design allowed me to configure it for shorter beams, and the plasma cutting mode handles 15mm carbon steel like a pro. Setup took under a day, and the touchscreen CNC interface made programming simple—even for someone not tech-savvy. It’s already paid for itself in labor savings."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Lin - Structural Steel Contractor

"Running multiple job sites, we needed reliable, on-demand H-beam cutting. This machine (Pro Model) was delivered in May 2025 and has been operating nonstop. The AI-enabled adaptive controls adjust cutting parameters based on material thickness, which has minimized torch wear and improved edge quality. We especially appreciate the ±0.1mm accuracy on complex bevel angles—weld prep is now seamless. Only downside: initial calibration required a technician visit, but support was responsive and on-site within 24 hours."Purchase Date: May 2025 | Usage Period: 3 months

⭐⭐⭐⭐⭐ Maria Thompson - Production Engineer, AutoFrame Solutions

"We integrated the Advanced Model into our chassis production line in January 2025. The CNC plasma system’s ability to program precise 45° bevels with servo-driven consistency has eliminated manual grinding steps. Cycle times dropped by 45%, and material waste is down 30%. The machine’s CE certification and emergency stop features gave our safety team full confidence. It’s one of the best automation investments we’ve made this year."Purchase Date: January 2025 | Usage Period: 7 months

⭐⭐⭐⭐☆ Ahmed Khalil - Maintenance Supervisor, Offshore Fabricator

"We’ve been using the Pro Model since March 2025 for repairing and modifying large H-beam structures. The 12m max workpiece capacity and robust steel frame handle our heaviest loads. Plasma preheating is noticeably faster than our old oxy-fuel system, and downtime between cuts is minimal. The modular conveyor system was customized to fit our bay layout—something competitors couldn’t offer. Only improvement? More detailed diagnostics in the CNC software would help troubleshoot minor alignment drifts faster."Purchase Date: March 2025 | Usage Period: 5 months

Average Rating: 4.8/5 ⭐ (89 Reviews)

Dr. Alan Foster - Industrial Automation Consultant

"This CNC Plasma Beam Coping Machine sets a new benchmark in H-beam processing. Its servo motor integration and modular scalability make it suitable for everything from SMEs to large-scale fabricators. The Pro Model’s AI-driven adaptation and ±0.1mm accuracy align with Industry 4.0 standards. I recommend it for any operation seeking to reduce manual labor and improve cutting consistency."

Linda Park - Senior Advisor, Construction Tech Review Board

"After evaluating over a dozen metal cutting systems, this machine stands out for its real-world adaptability. The ability to customize conveyor width and robotic reach ensures it fits seamlessly into existing production lines. Combined with CE and ISO safety compliance, it’s a top choice for structural steel projects requiring precision and safety."

Posted: 2 days ago

"Using the Advanced Model for bridge components. The beveling accuracy has cut our welding time in half. Setup was smooth, and the team adapted quickly to the CNC interface. Highly recommend for any serious fabrication shop."

Posted: 1 week ago

"Purchased the Base Model for prototyping. It handles stainless steel and aluminum with clean, warp-free cuts. The customization options exceeded expectations. Customer support helped us tune the servo speed for thicker materials—outstanding service."

Posted: 3 weeks ago

"Great machine, but the AI features in the Pro Model require a learning curve. Once trained, efficiency jumped dramatically. Suggest more onboarding resources for new users."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.