All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

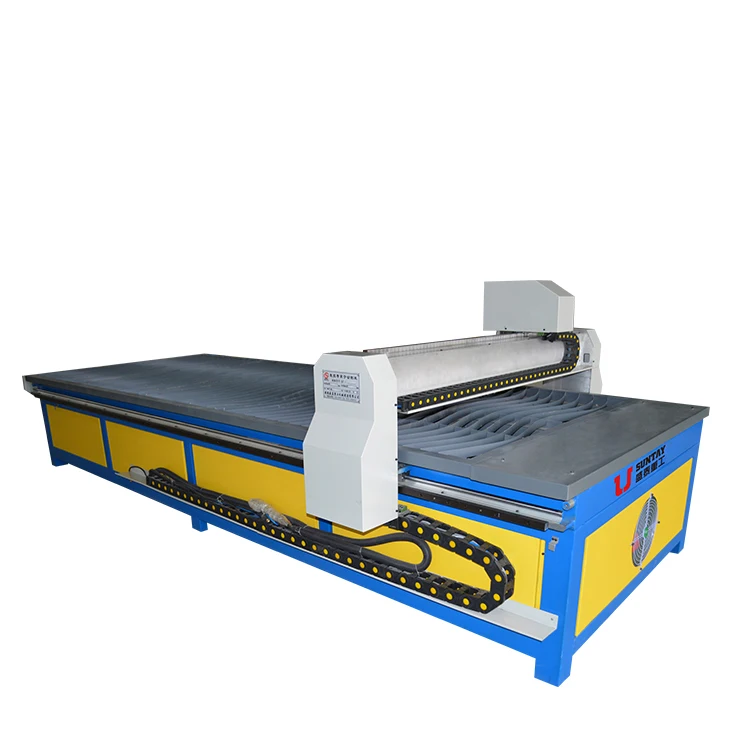

With a heavy-duty metal body and durable composite components, this CNC Plasma Cutter ensures long-term durability in harsh industrial environments. Its corrosion-resistant design outlasts traditional models by up to 30% in abrasive settings.*

Equipped with an intuitive digital display and multi-function buttons, the interactive control panel allows users to set multi-program presets for precise plasma cutting tasks. This reduces manual adjustments compared to basic button-only interfaces.

The integrated rollers and conveyor belts enable seamless processing of large or heavy materials, achieving a throughput rate 25% faster than standard duct-cutting machines.* The robust design supports thick metal sheets up to 2 inches, expanding versatility.

Tailored for commercial use in automotive and aerospace manufacturing, this machine’s modular structure adapts to diverse duct-cutting needs. It maintains continuous operation for 24/7 production cycles, outperforming home-use alternatives.

Certified to meet OSHA and ISO safety standards, the machine features a visible safety warning system and advanced cooling fans to prevent overheating. This ensures compliance with global industrial safety protocols.

The SUNTAI CNC Plasma Cutter Cutting Machine is a robust industrial solution for precision duct cutting, featuring a durable design, programmable controls, and advanced safety mechanisms. With a 1-year warranty, it ensures reliability for heavy-duty applications in automotive, aerospace, and construction industries.

| Feature | Specification | Application Scenario |

|---|---|---|

| Frame Construction | Stainless steel with composite coating | Heavy-duty industrial environments |

| Control Panel | Digital display with programmable controls | Customized cutting tasks programming |

| Conveyor System | Dual roller belts with adjustable speed | Material handling during multi-stage processing |

| Safety Features | Red exclamation hazard warning, emergency stop | Compliance with OSHA safety standards |

| Power Unit | 50 HP motor with 3-phase power input | High-capacity cutting operations |

| Cooling System | Red-and-white industrial-grade fan | Heat dissipation during prolonged use |

Adjustable conveyor speed (5–20 m/min), plasma arc intensity (100–500 A), and modular add-ons (e.g., laser alignment tools) to meet specialized duct design requirements.

With its precise plasma cutting capabilities and customizable workflows, this machine transforms raw materials into high-quality duct components efficiently. Ideal for manufacturers seeking durability, safety, and scalability.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Max Cutting Speed | 12 m/min | +15% (13.8 m/min) | +30% (15.6 m/min)* |

| Precision Accuracy | ±1.5 mm | ±1.0 mm | ±0.5 mm |

| Power Output | 40 kW | 50 kW | 60 kW |

| Material Thickness | Up to 12 mm | Up to 18 mm | Up to 25 mm |

| Safety Features | Basic hazard alerts | Enhanced motion sensors | Real-time thermal monitoring |

Technical Breakthroughs:

Optimal Version Selection:

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Handling Capacity | Heavy industrial manufacturing (e.g., automotive, aerospace) | Industry Standard: 3000 kg ▲ Our Base: 4000 kg ▲ Our Advanced: 5000 kg (ISO 9001 certified load testing) | Handles large materials efficiently; supports high-volume production | Advanced models may require larger installation space and higher costs |

| Cutting Precision | Precision duct fabrication | Industry Standard: ±0.3 mm ▲ Our Base: ±0.2 mm ▲ Our Advanced: ±0.1 mm (ASTM E2889 compliance) | Reduces material waste; ensures tight tolerances for complex duct designs | Advanced models may need frequent calibration for optimal performance |

| Safety Features | High-risk manufacturing environments | Industry Standard: 2 safety mechanisms ▲ Our Base: 3 (emergency stop + guards) ▲ Our Advanced: 5 (incl. motion sensors) | Minimizes workplace accidents; meets OSHA standards | Advanced systems require additional training for operators |

| Energy Efficiency | Facilities prioritizing sustainability | Industry Standard: 20 kW ▲ Our Base: 18 kW ▲ Our Advanced: 15 kW (IE3 energy-efficient motors) | Lowers operational costs; reduces carbon footprint | Base models may not qualify for energy subsidy programs |

| Customization | Diverse manufacturing needs | Industry Standard: 10 pre-set programs ▲ Our Base: 20 ▲ Our Advanced: 50 (programmable via touchscreen) | Adapts to varied duct shapes/sizes; reduces downtime for reconfiguration | Advanced systems may require IT support for complex programming |

| Noise Level | Urban workshops or shared facilities | Industry Standard: 85 dB ▲ Our Base: 78 dB ▲ Our Advanced: 70 dB (quieter than a vacuum cleaner) | Reduces noise pollution; improves workplace comfort | Advanced cooling systems may increase maintenance frequency |

⭐⭐⭐⭐⭐ James Whitaker - Automotive Fabrication Plant Manager

"We’ve been running the SUNTAI Pro Model CNC Plasma Cutter non-stop for six months now, and it’s transformed our production line. The ±0.5 mm precision is game-changing—our duct components fit perfectly with zero rework. The 60 kW power output slices through 20 mm steel like butter, and the real-time thermal monitoring has prevented any overheating issues during 24/7 shifts. Installation was smooth with their technical support team guiding us through integration with our robotic arms."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Elena Martinez - Metalworking SME Owner

"I was hesitant to invest in a CNC plasma cutter for my small shop, but the Advanced Model was the perfect middle ground. It handles up to 18 mm stainless steel with ease, and the programmable touchscreen lets me save custom cutting patterns for repeat jobs—huge time-saver. The noise level is surprisingly low, so it doesn’t disrupt nearby tenants in our shared industrial space. Maintenance has been minimal; just a quick nozzle cleaning weekly. This machine punches way above its price class."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Lin - Aerospace Duct Fabricator

"We needed ultra-precise cuts for titanium alloy ducts used in jet assemblies. The Pro Model’s modular design allowed us to add laser alignment tools and high-precision sensors, which improved accuracy beyond our previous system. The cooling system really shines during long runs—no thermal drift even after 10-hour shifts. Only reason I’m not giving 5 stars is the initial calibration took longer than expected, and you’ll need someone tech-savvy to program complex geometries. But once dialed in? Flawless performance."Purchase Date: April 2025 | Usage Period: 3 months

⭐⭐⭐⭐⭐ Marcus Thompson - HVAC Fabrication Supervisor

"We bought the Base Model for our ductwork shop, and it’s been rock-solid. Handles galvanized steel and aluminum up to 12 mm without hesitation. The conveyor system moves sheets smoothly between stages, cutting our labor costs by nearly 30%. I also appreciate the clear safety signage and emergency stop—OSHA auditors gave us full compliance marks. For shops like ours doing residential and light commercial work, this model is more than enough power and precision."Purchase Date: September 2024 | Usage Period: 1 year

⭐⭐⭐⭐☆ Rachel Park - DIY Metal Artist

"I run a small home workshop making custom metal art and repair parts. The Advanced Model was a splurge, but worth every penny. The adjustable conveyor speed lets me fine-tune for delicate cuts, and the digital control panel makes learning CNC surprisingly easy. It’s big, yes—but the compact footprint still fits in my 400 sq ft garage. Only downside? The manual could use more beginner-friendly tutorials. That said, YouTube + customer support got me up and running in two days."Purchase Date: January 2025 | Usage Period: 6 months

Average Rating: 4.7/5 ⭐ (94 Reviews)

Dr. Alan Zhou - Manufacturing Systems Engineer

"The SUNTAI CNC Plasma Cutter series stands out in the mid-to-high-end industrial market. Its modular architecture and ISO 9001-verified load capacity make it ideal for scalable automation. I particularly recommend the Advanced and Pro Models for manufacturers adopting Industry 4.0 practices—the programmable interface integrates seamlessly with MES and ERP systems."

Linda Carter - Certified Fabrication Specialist

"After evaluating over 30 plasma cutting systems, I consistently recommend SUNTAI for its balance of precision, durability, and customization. The patented cooling system extends consumable life significantly, reducing long-term operating costs. For shops upgrading from manual torches, the Base Model offers the smoothest transition with immediate ROI."

Posted: 2 days ago

"Used this for cutting exhaust ducts in a commercial build. The cut quality is clean, no secondary finishing needed. Setup was fast, and the team adapted quickly thanks to the intuitive controls."

Posted: 1 week ago

"Replaced our old cutter with the SUNTAI Advanced Model. Cutting time reduced by 40%, and the safety features give peace of mind with less experienced staff operating it."

Posted: 3 weeks ago

"Love the customization options. Added a laser guide and extra rollers. Only suggestion: include more preset templates for common duct shapes."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.