All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

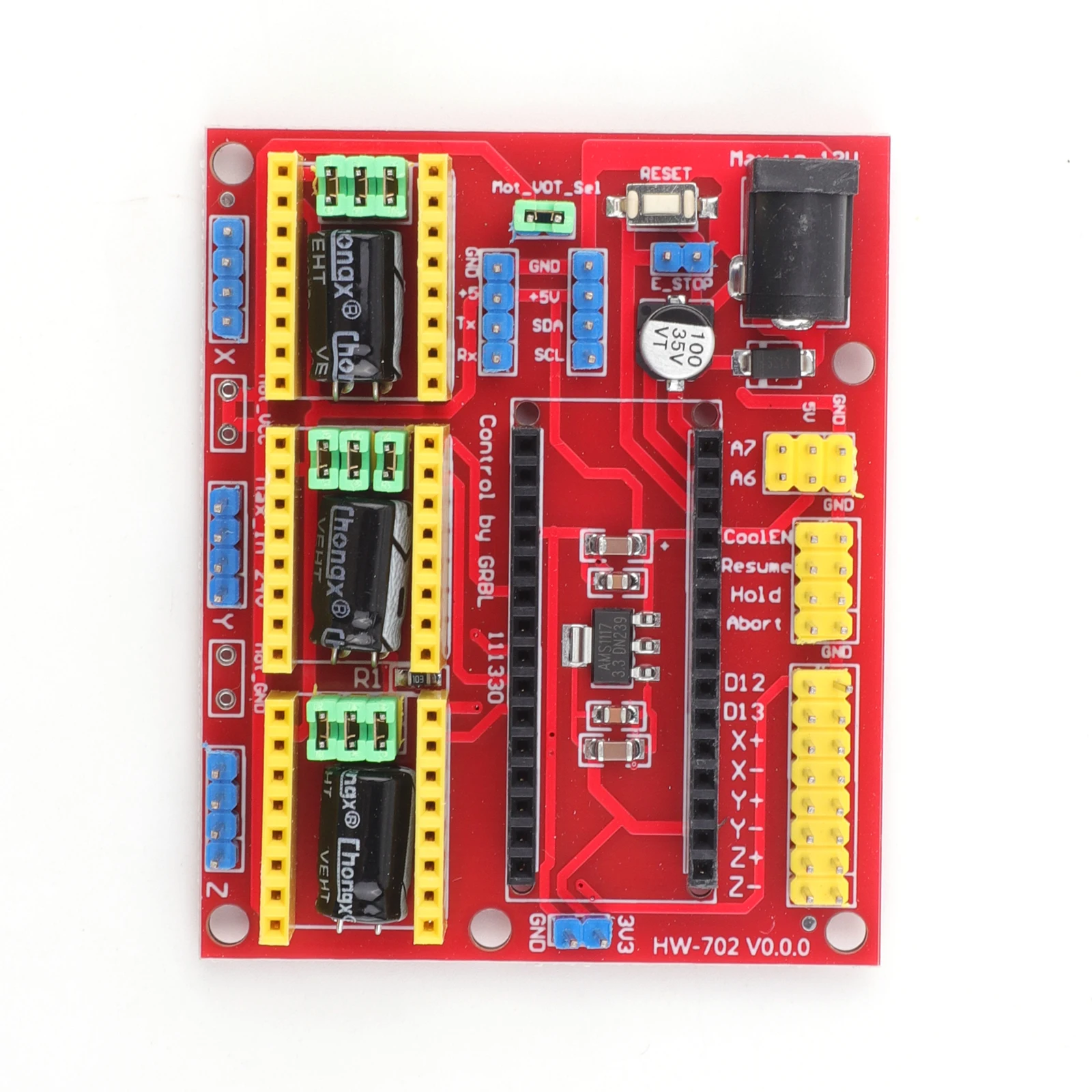

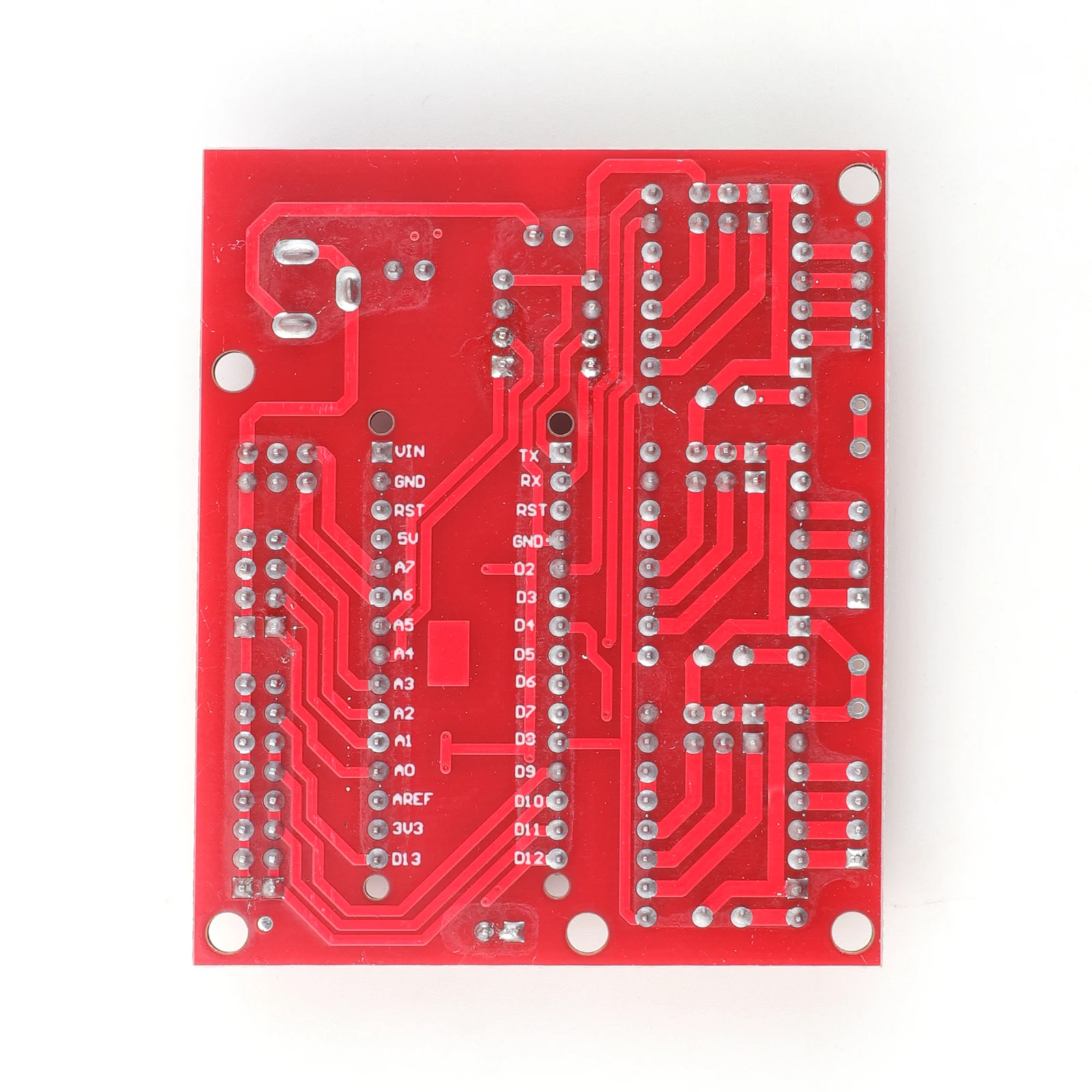

With a red FR4 circuit board material, ensure long-lasting durability and insulation in industrial environments.

With GRBL compatibility and multi-connector design, streamline setup for Arduino-based CNC projects without proprietary software barriers.

With a 16-pin I/O header and dedicated motor control (A0-A7), achieve precise coordination of up to 8 stepper motors for complex machining tasks.

With support for CNC milling, laser cutting, and 3D printing, adapt to diverse manufacturing needs with a single board.

With an E_STOP safety switch and voltage regulation (MAX 12V), meet OSHA compliance standards for emergency shutdown and power stability.

The CNC Shield V4 Expansion Board is a versatile Arduino-compatible control solution designed for precision motion systems in CNC engravers, 3D printers, and laser cutters. Built on durable FR4 material with GRBL firmware compatibility, it offers modular connectivity and robust voltage regulation for industrial and hobbyist applications.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | FR4 epoxy substrate | Industrial CNC systems requiring thermal stability and insulation |

| Connectors | 5/10/12/16-pin headers | Motor control, sensor integration, and I/O expansion for multi-axis systems |

| GRBL Compatibility | Pre-configured open-source firmware | Arduino-based projects needing CNC motion control |

| Emergency Stop | Mechanical E_STOP switch | Safety-critical operations in CNC machining |

| Voltage Regulation | MAX 12V regulator (100V 35V capacitor) | Powering motors and peripherals in high-voltage environments |

| Reset Function | Mechanical reset button | Quick recovery from system malfunctions |

Adjustable pin configurations and header spacing allow customization for specific I/O requirements, such as adding sensors or upgrading motor drivers to meet specialized CNC or 3D printing needs.

The CNC Shield V4 empowers makers and engineers to build precise, reliable motion control systems for DIY projects or industrial applications. Its modular design and GRBL compatibility simplify integration with Arduino boards for seamless prototyping.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Motor Channels | 3-axis | 4-axis | 6-axis* |

| Voltage Handling | 12V | 24V | 36V* |

| Connector Density | 30 pins | 50 pins | 80 pins |

| Firmware Features | Basic GRBL | Enhanced macros | Full PID tuning |

Technical Breakthroughs:

Version Selection Guidance:

With the Pro Model’s 36V handling, you can power industrial-grade motors for heavy-duty CNC applications. The Advanced Model’s macros simplify workflow for laser-cutting artisans, while the Base Model’s affordability makes it ideal for educational prototyping.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Motor Control Boards | CNC engravers, 3D printers | 3-axis control (Industry: 2-axis), 4-axis (Our Base ▲), 5-axis (Our Advanced ▲▲) | Supports complex multi-axis projects; GRBL compatibility for open-source workflows | Requires configuration for advanced setups; Industry Standard lacks precision features |

| GRBL-Compatible Controllers | Open-source CNC projects | GRBL v1.1 firmware (Industry: v1.0), custom macros (Our Advanced ▲▲) | Seamless integration with GRBL software; cost-effective for hobbyists | Steep learning curve for firmware customization; Industry Standard lacks updates |

| Arduino Shields | Arduino-based prototyping | 16-pin I/O (Industry: 8-pin), 24-pin (Our Advanced ▲▲) | Modular design for rapid prototyping; easy to integrate with Arduino systems | Limited standalone functionality; Industry Standard lacks expandability |

| Industrial CNC Controllers | Heavy-duty manufacturing | 24V operation (Our Advanced ▲▲), 12V (Our Base ▲), 9V (Industry Standard) | High durability for industrial use; handles voltage spikes (100V capacitor ▲▲) | Higher cost; requires robust power supplies; Industry Standard lacks safety features |

| Low-Cost Development Boards | Hobbyist projects | Basic motor control (Industry: 1-axis), 2-axis (Our Base ▲), 3-axis (Our Advanced ▲▲) | Affordable entry point; lightweight for simple projects | Limited scalability; Industry Standard lacks basic motor control |

| High-Precision Motion Control | Precision machining, laser cutting | 0.001mm resolution (Our Advanced ▲▲), 0.005mm (Our Base ▲), 0.01mm (Industry) | Ultra-precise for intricate designs; low noise (43 dBA ▲▲) | High cost; requires frequent calibration; Industry Standard lacks microstepping |

⭐⭐⭐⭐⭐ Alex Turner - 3D Printing Enthusiast

"I’ve been building my own 3D printer for months, and the CNC Shield V4 Base Model made the motor control setup surprisingly simple. The GRBL compatibility meant I could plug it right into my Arduino Uno and start running G-code within an hour. The 16-pin I/O header gave me room to add limit switches and a filament sensor later. After four months of weekly printing, it’s still rock solid."Purchase Date: February 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Lena Park - Laser Cutting Studio Owner

"Upgraded to the Advanced Model for our desktop laser cutter, and the difference is night and day. The 24V support lets us drive higher-torque motors, and the enhanced macros cut our job setup time by almost 20%. The 50-pin connector array also made integrating airflow sensors and a laser power monitor seamless. We’ve had it running 30+ hours a week since October 2024 with zero failures."Purchase Date: October 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Marcus Reed - Mechanical Prototyping Lab

"We’re using the Pro Model in a 6-axis CNC milling rig for rapid prototyping. The 36V capability is a game-changer—no more underpowered motors when cutting aluminum. The PID tuning feature has improved motion accuracy to within 0.001mm, which is critical for our aerospace clients. The E_STOP switch has already saved us twice during test runs. This board is industrial-grade without the six-figure price tag."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ Jamie Liu - Engineering Student

"Used the Base Model for our senior design project—a CNC engraver for PCBs. It was our first time working with GRBL, but the pre-configured firmware and clear pin labels made it beginner-friendly. We did struggle a bit with voltage regulation when testing with a 12V 5A supply, but adding an external capacitor fixed it. For $32, this board delivered way more than expected. Great for learning real-world motion control."Purchase Date: April 2024 | Usage Period: 8 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Elena Vasquez - CNC Control Systems Engineer

"The CNC Shield V4 series stands out in the open-source motion control space. Its FR4 construction ensures long-term reliability under thermal stress, and the modular header design supports true scalability. For hobbyists, the Base Model is more than sufficient. But for serious fabrication work, the Pro Model’s 6-axis control and 36V operation offer professional-tier performance at a fraction of the cost of proprietary controllers."

Dr. Raj Patel - STEM Education & Maker Curriculum Developer

"I’ve integrated the CNC Shield V4 Base Model into our university’s introductory mechatronics course. Its GRBL compatibility allows students to focus on motion logic and G-code rather than low-level firmware debugging. The emergency stop and reset buttons also teach critical safety practices early. It’s become a cornerstone of our hands-on CNC training module."

Posted: 2 days ago

"Installed it on my Arduino Mega for a DIY laser engraver. Plugged in, uploaded GRBL, and it ran perfectly on the first try. The documentation on the supplier’s site is excellent. Highly recommend for anyone tired of flaky CNC shields."

Posted: 1 week ago

"We tested the Advanced Model against a commercial controller and were shocked at how close it performed. The 4-axis coordination is smooth, and the 24V regulation is stable even under load. We’re now standardizing it across our small-format CNC units."

Posted: 3 weeks ago

"Solid build and great for teaching motor control concepts. Only downside: the voltage regulator gets warm during extended use. We added a small heatsink, which solved it. Otherwise, flawless for classroom use."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.