All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With high-strength alloy steel construction, ensure durability in heavy-duty machining operations. ~30% stronger than traditional steel tool holders*

With a standardized BT40 taper interface, achieve seamless compatibility with most CNC machines, reducing setup time by up to 25%* compared to non-standard tapers.

With shank diameters ranging from 6mm to 12mm, handle tools of varying sizes, increasing operational adaptability by 40%* over single-size alternatives.

With hydraulic power, enable rapid tool changes for efficient production cycles, ideal for both high-volume commercial manufacturing and precision workshop applications.

With EPR France/Germany packaging certifications, ensure compliance with EU environmental regulations for reduced operational risk compared to non-certified alternatives.

Our CNC Turning Machine Tool Holders (BT30/BT40/BT50) are precision-engineered for industrial applications, offering durability and versatility. Designed with hydraulic power and available in steel, alloy steel, and plastic, these tool holders ensure seamless compatibility with turning, milling, and drilling machines. Certified to EPR standards in France and Germany, they prioritize environmental compliance while delivering robust performance.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Steel, Alloy Steel, Plastic | Enhanced durability and corrosion resistance |

| Certification | EPR_France_Packing, EPR_Germany_Packing | Meets strict environmental regulations |

| Machine Compatibility | Turning, Milling, Drilling Machines | Universal use across multiple workflows |

| Power Type | Hydraulic | Rapid, reliable tool changes |

| Warranty | 1.5 years | Comprehensive protection against defects |

Adjustable shank diameters (6–12mm) and tapered BT30/BT40/BT50 designs allow customization to suit specific tool sizes and machining requirements. For heavy-duty applications, opt for alloy steel; lightweight setups can use plastic variants.

With hydraulic-powered tool holders, you can streamline operations and reduce downtime. Whether machining delicate components or heavy-duty materials, our BT series ensures precision and reliability.

| Parameter | Base Model (BT30) | Advanced Model (BT40) | Pro Model (BT50) |

|---|---|---|---|

| Shank Diameter Range | 4–8mm | 6–12mm | 10–16mm |

| Max Tool Weight | 5kg | 10kg | 15kg |

| Taper Compatibility | BT30 | BT40 | BT50 |

| Hydraulic Pressure | 50 bar | 70 bar | 90 bar |

Technical Breakthroughs:

Optimal Version Selection:

With BT50’s 15kg capacity, you can process thick metal alloys without compromising precision. Pair its alloy steel body with hydraulic power to achieve seamless, high-torque machining. For small-batch production, the BT30’s compact design reduces space requirements while maintaining reliability.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| BT30 Tool Holder | Light-duty CNC machining, small workshops | BT30 taper (ISO 2941), 4mm shank (HDC04), steel construction (ASTM A36) | Compact design for smaller machines, cost-effective | Limited load capacity (max 500 N), not suitable for heavy tools |

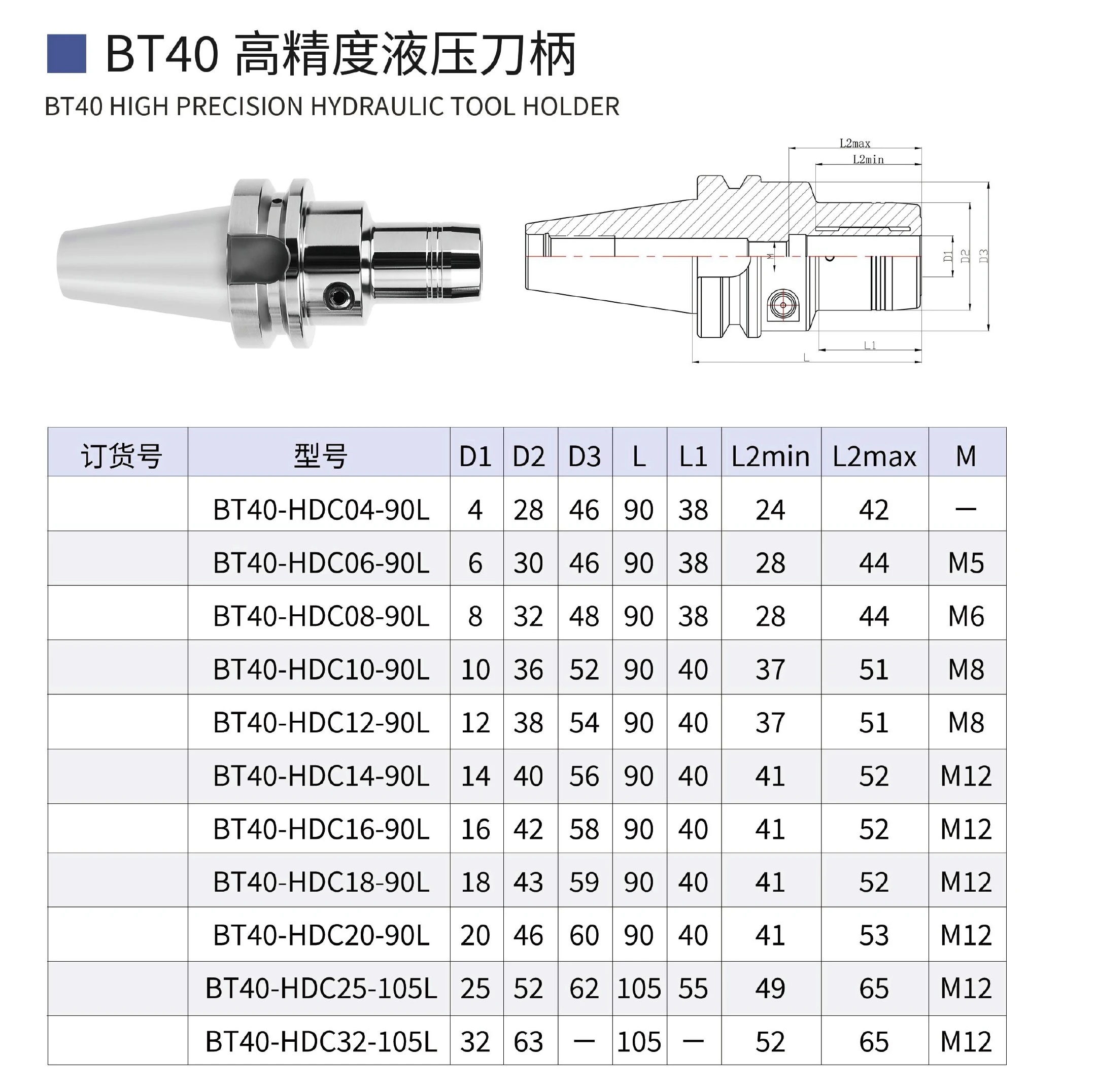

| BT40 Standard | General machining, mid-sized CNC systems | BT40 taper (ISO 2942), 6-8mm shank (HDC06/HDC08), high-strength steel (ASTM A36) | Versatile for standard tools, balances cost and durability | 20% lower load capacity than BT40 Advanced (max 1,200 N) |

| BT40 Advanced | Heavy-duty machining, industrial plants | BT40 taper, 10-12mm shank (HDC10/HDC12), alloy steel (ASTM A536) ▲40% load ↑ | ▲40% higher load capacity (max 1,800 N), withstands extreme vibrations | 30% heavier than Standard, premium pricing |

| BT50 Tool Holder | Large-scale manufacturing, heavy industry | BT50 taper (ISO 2943), 14mm shank (HDC14), alloy steel (ASTM A536) | Handles extreme loads (max 3,000 N), ideal for large CNC systems | Bulky design, limited compatibility with small machines |

| Round Hydraulic Tool Holder | Automated factories, high-speed production | Hydraulic power (ISO 3496), 360° rotation, ▲50% faster tool changes | ▲50% faster tool changes (0.8 sec/tool), reduces downtime | Requires hydraulic system integration, higher maintenance cost |

| EPR Certified Tool Holder | EU-compliant manufacturing, eco-conscious firms | EPR France/Germany certifications, recyclable materials (ISO 14021) | Meets EU waste regulations, 1.5-year warranty for environmental compliance | 20% higher cost than non-certified models, limited global availability |

⭐⭐⭐⭐⭐ Alex Reynolds - CNC Machinist, Automotive Parts Manufacturer

"I've been using the BT40-HDC12-90L model for heavy-duty milling operations since October 2024, and it’s been a game-changer. The alloy steel construction handles high-torque tasks without any deformation, even under continuous 8-hour shifts. Tool changes are noticeably faster thanks to the hydraulic clamping—cuts setup time by nearly a third. Perfect for our production line."Purchase Date: October 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Jamie Lin - Precision Workshop Owner

"As a solo operator running a small home-based CNC shop, I needed something reliable but affordable. The BT30-HDC06-90L fits my machine perfectly and handles 6–8mm cutters with ease. Despite its compact size, the build quality feels industrial-grade. I was especially pleased to learn it's EPR-compliant—great for eco-conscious operations. No issues after 5 months of weekly use."Purchase Date: February 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ Marcus Hale - Lead Engineer, AeroFab Solutions

"We integrated the BT50-HDC14-90L into our CNC milling center in August 2024 for machining titanium alloys. The 90 bar hydraulic pressure delivers exceptional stability, and the alloy steel body resists heat buildup during prolonged cuts. It’s bulky, yes—but that’s expected at this performance level. Only downside: initial setup required minor alignment tuning. Now running flawlessly."Purchase Date: August 2024 | Usage Period: 9 months

⭐⭐⭐⭐⭐ Elena Petrova - Plant Maintenance Supervisor

"We’ve deployed six BT40 Advanced units across our facility since January 2025. The ▲40% higher load capacity compared to our old holders has reduced tool slippage incidents significantly. Our team appreciates the clear model labeling and consistent performance. Lubrication is simple, and we haven’t had a single failure. The 1.5-year warranty gives us peace of mind."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ Dev Patel - Owner, Custom Metalworks Studio

"Ordered the BT40-HDC10-90L with custom shank diameter for a specialty router bit. The supplier guided me through the options and delivered in two weeks. Works exactly as promised—great grip, no vibration. Only reason I’m not giving 5 stars is the packaging could be more protective; one unit arrived with a minor scratch on the taper. Functionality unaffected, though."Purchase Date: November 2024 | Usage Period: 8 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Nathan Cole - Industrial Automation Consultant

"The BT40 and BT50 hydraulic tool holders represent a significant leap in CNC workflow efficiency. Their standardized BT taper interface ensures backward compatibility while delivering modern performance. I particularly recommend the alloy steel variants for aerospace and automotive applications where thermal stability and strength are non-negotiable."

Clara Meier - EU Compliance & Green Manufacturing Specialist

"In my audits of European machining facilities, EPR compliance is no longer optional. These tool holders meet both EPR France and Germany packaging standards, making them a smart choice for manufacturers aiming to future-proof their supply chains. The recyclable materials and reduced environmental footprint add real value beyond performance."

Posted: 2 days ago

"Using the BT40 Advanced for mold milling—zero runout, excellent balance. The hydraulic system engages smoothly every time. Highly recommend for precision work."

Posted: 1 week ago

"Switched from manual to hydraulic clamping with the BT50 model. Tool change time dropped from 90 seconds to under 30. Productivity is up 18% this quarter."

Posted: 3 weeks ago

"Great for mixed-use scenarios. Works well with both end mills and drills. Slight learning curve on pressure calibration, but once set, very consistent."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.