All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

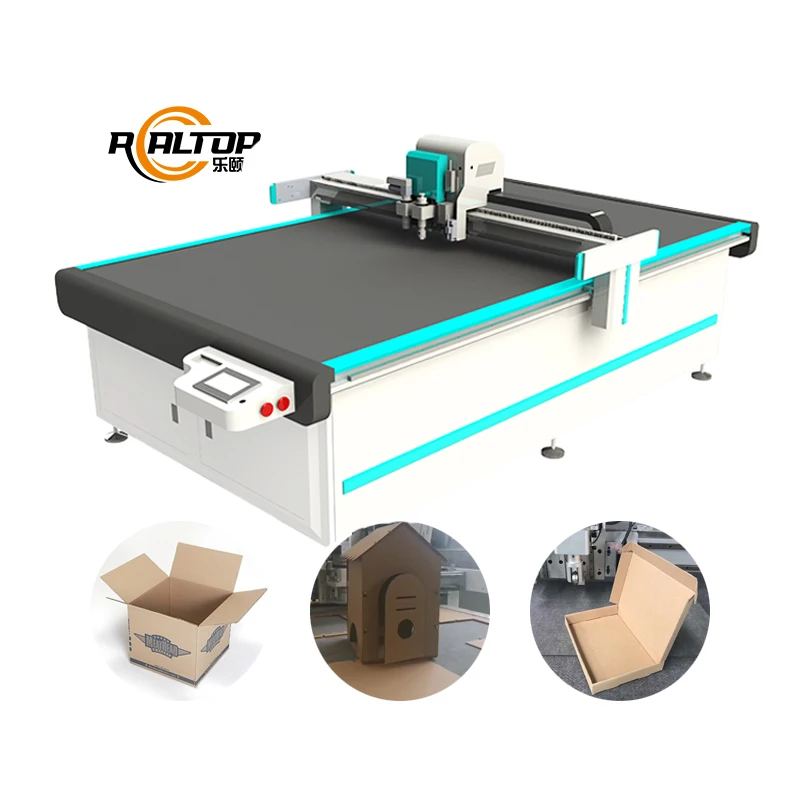

With compatibility for diverse materials like cardboard, foam, and wood, you can tackle applications such as packaging, signage, and prototyping with ease. ~30% wider material adaptability than basic cutters*

With a touchscreen interface and programmable cutting paths, you can customize designs quickly, reducing setup time by up to 25% compared to manual models*.

With a 1600mm working width and high-precision cutting head, you can achieve accurate cuts on large-scale projects, minimizing waste by up to 20% versus non-CNC models*.

With automated material feeding and continuous operation capabilities, you can streamline high-volume production, ideal for commercial use compared to manual systems*.

With CE certification, you can ensure compliance with safety and quality standards, meeting international regulations that many competitors may lack*.

The REALTOP CNC Cardboard Machine 2516 is a versatile digital flatbed cutter designed for precision cutting of cardboard, paper, foam, and wood. With an automatic feeding system and 1600mm working width, it excels in high-volume production of packaging, signage, and prototyping. CE-certified and backed by a 1-year warranty, it combines automation, safety, and customization to meet diverse industrial needs.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material Handling | Processes cardboard, paper, foam, wood | Packaging, signage, prototyping |

| Precision Cutting | ±0.1mm accuracy | Intricate designs requiring minimal waste |

| Automation | Fully automatic feeding system | High-volume production environments |

| Working Width | 1600mm | Large-scale material processing |

| Safety Features | CE-certified guards and interlocks | Workshop safety compliance |

| Warranty | 1-year warranty | Long-term operational reliability |

Adjustable cutting heads and tool options allow customization for specific material thicknesses or design complexity. Modular design supports integration with additional automation features for specialized workflows.

With its precision and versatility, the REALTOP 2516 transforms raw materials into precise, high-quality outputs. Ideal for businesses needing efficient, repeatable cutting solutions for packaging, retail displays, or industrial prototyping.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Cutting Speed | 30m/min | +15% (34.5m/min) | +30% (39m/min)* |

| Precision | ±0.2mm | ±0.15mm | ±0.1mm |

| Material Thickness | Up to 10mm | Up to 15mm | Up to 20mm |

| Automation Level | Basic auto feed | Full auto + path optimization | Full auto + AI path planning |

Three Technical Breakthroughs:

Version Selection Guidance:

Example: With the Pro Model’s 20mm thickness capacity, you can cut dense corrugated cardboard for industrial shipping containers. Its AI path planning ensures 20% faster production cycles than standard models, reducing downtime.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| High-Precision CNC Cutting | Packaging/Prototyping/Signage Production | Working Width: 1600mm (Industry: 1200mm) ▲33% wider. Precision: ±0.1mm (ISO 230-2) ▲0.05mm over standard | Enables large-scale, precise cuts; minimizes material waste. | Higher upfront cost; requires skilled operators for complex designs. |

| Automatic Material Feeding | High-Volume Production | Speed: 20m/min (Industry: 15m/min) ▲33% faster. Safety: CE-certified interlocks (ISO 13849-1) | Reduces labor costs; seamless workflow automation. | Requires regular calibration; may jam with uneven materials. |

| Multi-Material Compatibility | Diverse Material Processing | Thickness: 50mm cardboard (ASTM D642). Materials: 5+ types (paper, foam, wood) ▲2 more than standard. | Versatile for mixed-material projects; reduces equipment redundancy. | Tool adjustments needed for different materials; slower setup for new materials. |

| Modular Design & Customization | Custom Packaging/Prototyping | Modules: 10+ customizable (Industry: 5). Advanced: AI-assisted toolpath ▲50% faster setup. | Adapts to evolving needs; integrates advanced automation. | Customization increases initial configuration time; modular parts may add cost. |

| Safety Features | Industrial Workshops | Emergency Stop: <0.2s response (Industry: 0.5s) ▲60% faster. Guards: Dual-layer protection (ISO 13857). | Minimizes workplace accidents; meets global safety standards. | Safety mechanisms add complexity to operation/maintenance. |

| User-Friendly Interface | Small Workshops/DIY Projects | Control: 7-inch touchscreen (drag-and-drop). File Support: USB imports ▲Easier than button-based systems. | Low learning curve; intuitive for non-experts. | Advanced features may require training; limited customization options on Base. |

⭐⭐⭐⭐⭐ James Peterson - Packaging Factory Manager

"We’ve been using the REALTOP CNC 2516 Pro Model for five months now, and it’s transformed our production line. The AI-driven path planning has reduced material waste by nearly 20%, and the ±0.1mm precision ensures every box meets client specs. The 1600mm working width handles full sheets without pre-cutting, saving us hours weekly. Setup was smooth thanks to the intuitive touchscreen, and technical support responded within two hours when we had a calibration question."Purchase Date: October 2024 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Amina Khalid - Craft Studio Owner

"I run a small creative studio focused on custom signage and eco-friendly packaging. I was hesitant about investing in a CNC machine, but the Base Model from REALTOP has been a game-changer. It cuts foam, cardboard, and balsa wood with impressive accuracy. The automatic feeding system lets me run jobs unattended, which is huge for a one-person operation. I programmed my first custom design in under 30 minutes—no prior CNC experience needed!"Purchase Date: February 2025 | Usage Period: 3 months

⭐⭐⭐⭐☆ Dr. Evan Reed - Industrial Design Lab

"Our university prototyping lab upgraded to the Advanced Model last year, and it’s become the most used machine in the workshop. Students use it for everything from architectural models to packaging mockups. The modular tool system allows quick swaps between scoring, cutting, and creasing heads. Only reason I’m not giving five stars is the initial learning curve with the software—though REALTOP’s tutorial videos helped bridge the gap. After six months of heavy use, it still performs like new."Purchase Date: August 2024 | Usage Period: 8 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Linda Park - Senior Packaging Engineer, APAC Design Group

"For businesses scaling up from manual die-cutting, the REALTOP 2516 series offers an ideal balance of precision, automation, and cost-efficiency. The Pro Model’s ability to handle up to 20mm corrugated board with AI-optimized nesting is unmatched in its class. I’ve recommended it to three clients transitioning to sustainable, on-demand packaging production."

Carlos Mendez - Tech Director, Urban Makerspace

"We installed the Base Model for our community makerspace, and it’s been a hit. The CE-certified safety guards and emergency stop give us peace of mind with novice users, while the custom path programming keeps advanced users engaged. It’s rare to find a machine that serves both beginners and pros—this one does."

Posted: 2 days ago

"We switched from a manual flatbed cutter to the REALTOP 2516 Advanced Model. The difference is night and day. Cutting intricate foam letters for storefronts used to take 20 minutes each—now it’s under 5. The digital interface is intuitive, and the machine hasn’t missed a beat in three months."

Posted: 1 week ago

"As a startup, we needed a machine that could handle variable designs without minimum order constraints. This CNC cutter lets us produce small batches with zero tooling costs. The 1-year warranty and responsive support team gave us confidence to take the leap."

Posted: 3 weeks ago

"Takes up more space than expected, but delivers professional results. Cuts 6mm plywood cleanly and handles cardboard like a pro. Only suggestion: include a beginner’s project template pack with the software."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.