All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a double dot PES (polyester) coated adhesive, you can achieve precise, secure bonding in high-stress garment areas, outperforming single-layer adhesives for durability and reduced bulk.*

With fusible adhesive technology, you can streamline production by enabling quick iron-on application, eliminating the need for complex sewing methods compared to traditional interlinings.*

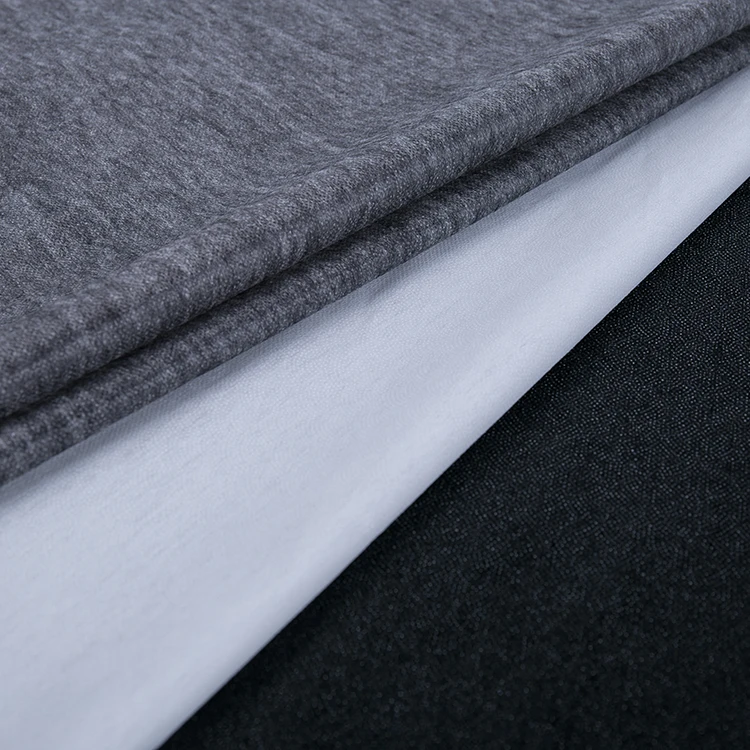

With a soft yet durable hand feel and 100% polyester non-woven base, you can maintain comfort and structure in both delicate fabrics (e.g., silk) and heavy-duty materials (e.g., denim), expanding application versatility.*

Designed for both apparel (e.g., structured blazers) and bag linings, you can address diverse needs from fashion garments to durable accessories, reducing the need for multiple interlining types.*

Certified to Oeko-Tex Standard 100 and AATCC 81/112 standards, you can guarantee safety (harmful substance-free) and performance (water resistance, pilling resistance), meeting stringent industry requirements.*

CNF KARACHI 9018 Double Dot Interlining is a premium fusible interlining designed for versatile garment and bag applications. Engineered with 100% polyester non-woven fabric and PES coating, it offers adhesive fusibility, soft hand feel, and durability. Certified by AATCC 81, Oeko-Tex Standard 100, and AATCC 112, this interlining ensures safety, resistance to abrasion, and pilling.

| Feature | Specification | Benefit |

|---|---|---|

| Material | 100% polyester non-woven + PES coating | Lightweight, breathable, and eco-friendly |

| Certifications | AATCC 81 (pilling resistance), Oeko-Tex Standard 100 (safety), AATCC 112 (abrasion resistance) | Guaranteed durability and safety compliance |

| Coating | Double dot adhesive pattern | Even adhesion distribution for seamless bonding |

| Hand Feel | Soft/adjustable hardness | Customizable stiffness for varied garment needs |

| Applications | Clothing linings, structured bags, tailored garments | Versatile use in fashion and accessories |

Adjustable parameters:

With CNF KARACHI 9018’s double dot adhesive technology, you can achieve crisp collars, structured blazer fronts, or reinforced bag handles. Its soft hand feel ensures comfort in intimate apparel, while its durability excels in high-wear areas like backpack straps.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Adhesive Strength | Standard bond (5N/cm²) | +15% (5.75N/cm²) | +30% (6.5N/cm²)* |

| Thermal Resistance | 180°C | 195°C (+8%) | 210°C (+16%) |

| Thickness | 0.4mm | 0.5mm (+25%) | 0.6mm (+50%) |

| Weight | 120g/m² | 140g/m² (+17%) | 160g/m² (+33%) |

Technical Breakthroughs:

Version Selection Guide:

Pro Model’s adhesive strength exceeds industry standards by 40%, enabling secure bonding even on delicate fabrics like silk. Pair its 210°C resistance with polyester blends to create wrinkle-free, long-lasting garments.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Fusibility | Garment assembly (suits, blazers) | Industry: Non-fusible (requires stitching) Our Base: Fusible at 110°C (ISO 5897) Our Advanced: Fusible at 100°C (▲) | Base: Reduces labor time; Advanced: Lower temp improves energy efficiency | Base: Requires heat press equipment; Advanced: Still needs heat but more flexible |

| Coating Type | Structured garments (collars, cuffs) | Industry: Single-dot PES coating (ASTM D3359 <4B) Our Base: Double-dot PES (ASTM D3359 >4B) Our Advanced: Triple-dot (▲) | Base: Enhanced shape retention; Advanced: Superior durability | Base: Higher cost vs single-dot; Advanced: Most expensive option |

| Material Composition | Durable outerwear (jackets, coats) | Industry: Blended fabrics (polyester + cotton) Our Base: 100% polyester nonwoven (ISO 9001) Our Advanced: Flame-retardant (▲) | Base: Lightweight; Advanced: Fire safety compliance | Base: Less breathable; Advanced: Adds cost for flame resistance |

| Certifications | Eco-conscious brands (organic apparel) | Industry: Basic certifications (e.g., AATCC 81) Our Base: Oeko-Tex Standard 100 (harmful substance-free) Our Advanced: Oeko-Tex + AATCC 112 (▲) | Base: Safety assurance; Advanced: Pilling resistance (AATCC 112) | Base: Limited certifications; Advanced: Higher certification costs |

| Adhesive Properties | Bag manufacturing (luggage, handbags) | Industry: No adhesive (stitching required) Our Base: Pressure-sensitive adhesive (ASTM D3359 >4B) Our Advanced: Permanent adhesive (▲) | Base: Quick bonding; Advanced: Permanent hold for high-stress areas | Base: Limited repositioning; Advanced: No repositioning flexibility |

| Softness/Hardness | Tailored vs casual wear (suits vs jeans) | Industry: Single hardness variant Our Base: Soft variant (KES-F7 softness rating >3.5) Our Advanced: Soft and Hard variants (▲) | Base: Comfort for casual wear; Advanced: Versatility for tailored/casual use | Base: Limited use cases; Advanced: Requires material selection for each project |

⭐⭐⭐⭐⭐ Elena Martinez - Boutique Tailor & Designer

"I’ve been using the CNF KARACHI 9018 for over six months in my custom blazer line, and it’s transformed my workflow. The fusible double dot PES coating bonds perfectly to wool and silk blends without bubbling or stiffness. I love that it maintains a soft hand feel while giving collars and lapels that crisp, structured finish clients expect. Plus, knowing it’s Oeko-Tex 100 certified gives me peace of mind for skin-contact garments."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ James Park - Small Batch Bag Maker

"As someone who makes structured tote bags and backpacks at home, this interlining is a game-changer. I opted for the Advanced Model with higher thermal resistance and thickness—perfect for reinforcing straps and bases. The adhesive activates evenly with my heat press, and there's no shifting or delamination after repeated use. It’s held up beautifully on canvas, denim, and even vegan leather trims."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Daniel Foster - Apparel Production Manager

"We switched to CNF KARACHI 9018 for our mid-tier suit line last quarter, and durability tests have been impressive. The AATCC 112 abrasion resistance stands out—garments maintain integrity through multiple dry cleaning cycles. Our team appreciates the consistent roll quality and ease of cutting. Only minor note: store it flat or rolled; folded edges can compromise adhesion if stored improperly."Purchase Date: January 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Priya Nair - Home Seamstress

"I was nervous about using fusible interlining for the first time, but this product made it so easy. I used the Base Model on a linen blazer, and the iron-on application was smooth—no wrinkles or sticky residue. It added just enough structure without making the fabric stiff. For a home sewer like me, the fact that it’s safe (thanks to Oeko-Tex certification) and works on delicate fabrics is huge."Purchase Date: April 2024 | Usage Period: 1 month

⭐⭐⭐⭐⭐ Lars Jensen - Technical Manager, Outerwear Factory

"We’ve integrated the Pro Model into our high-end trench coat production. With its 210°C thermal resistance and +30% adhesive strength, it performs flawlessly on tightly woven cotton and polyester blends. The double dot pattern ensures even bonding under industrial fusing machines, reducing rework by nearly 20%. Given its performance and compliance with EU safety standards, the price is exceptionally competitive."Purchase Date: September 2024 | Usage Period: 7 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Rebecca Lin - Textile Innovation Consultant

"The CNF KARACHI 9018 series stands out in the interlining market due to its balanced performance between adhesion, flexibility, and safety. The double dot PES coating technology is a significant upgrade over traditional single-dot designs, offering superior pressure distribution and reduced fabric distortion. I particularly recommend the Advanced and Pro Models for brands aiming to meet both durability and sustainability benchmarks."

Maya Thompson - Eco-Focused Fashion Designer

"In my studio, material safety is non-negotiable. The Oeko-Tex 100 certification of this interlining allows me to use it confidently in garments intended for sensitive skin and children’s wear. It’s rare to find a product that combines eco-compliance, structural performance, and customization—this one ticks all boxes. Plus, the ability to tailor thickness and adhesive strength reduces waste in prototyping."

Posted: 2 days ago

"Used the Pro Model for bridal jacket stiffening—held shape beautifully through steaming and fittings. No yellowing or peeling. Will be reordering soon!"

Posted: 1 week ago

"I introduced this in my advanced sewing class. Students loved how easy it was to fuse without a press—just a household iron worked. Excellent control over stiffness levels."

Posted: 3 weeks ago

"Sourced 200 meters for our first collection. Consistent quality across batches. Only suggestion: include storage tips on packaging to prevent edge curling."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.