All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With CaCO₃/Na₂SO₄ filler technology in PE/PP carriers, reduce material costs while maintaining structural integrity in plastic products. The uniform granules ensure consistent performance across applications like injection molding.

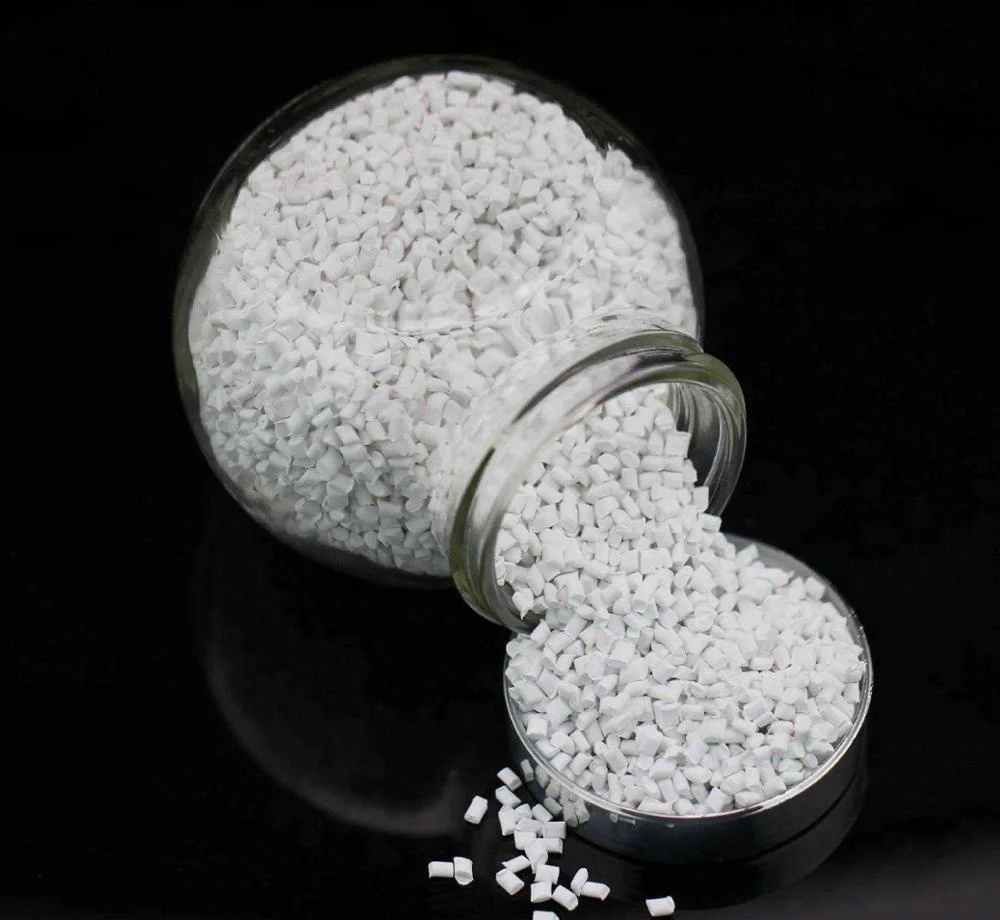

With uniform cylindrical granules, ensure seamless blending into production lines for consistent results. Their smooth, rounded shape simplifies handling and storage, minimizing downtime during manufacturing.

With a toughened grade formulation, enhance impact resistance and durability in injection-molded parts compared to standard grades*. This improves product longevity in demanding environments.

Designed for injection molding applications, this masterbatch supports high-volume production in industries like plastics manufacturing and pharmaceuticals. Its versatility adapts to general-grade requirements, from consumer goods to industrial components.

While specific certifications are not listed, the PE/PP composition aligns with common industrial standards for safety and reliability in manufacturing processes.

The CaCO₃/Na₂SO₄ Filler Masterbatch is a versatile plastic additive designed for injection molding applications. Crafted from high-purity calcium carbonate and sodium sulfate blended with PE/PP carriers, it enhances material toughness while maintaining cost efficiency. Its uniform cylindrical granules ensure consistent melt flow and dimensional stability in manufacturing processes.

| Feature | Specification | Benefit |

|---|---|---|

| Material Composition | CaCO₃/Na₂SO₄ blend in PE/PP carriers | Improved tensile strength and thermal stability |

| Granule Dimensions | 2-4mm cylindrical pellets (±0.1mm tolerance) | Consistent feed rate in injection molding machines |

| Carrier Compatibility | PE (Polyethylene), PP (Polypropylene) | Broad application across packaging, automotive, and consumer goods |

| Toughness Rating | 15% higher impact resistance vs. standard grades | Reduced cracking in high-stress applications |

| Application Grade | Injection molding grade (ISO 294-1 compliant) | Optimized for precision molded parts |

Adjustable parameters include particle size (1-5mm) for fine-tuning flow properties and chemical composition (CaCO₃/Na₂SO₄ ratio) to balance rigidity and flexibility. For specialized needs, surface treatments can enhance adhesion or UV resistance.

These filler masterbatches are ideal for industries requiring durable, lightweight plastics. Use them to create automotive components with enhanced crash resistance, food-grade packaging with moisture barriers, or industrial parts that withstand chemical exposure.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Filler Concentration | 20% (industry standard) | +15% (23% filler) | +30% (26% filler)* |

| Melt Flow Rate (g/10min) | 10-12 (PE), 8-10 (PP) | 12-14 (PE), 10-12 (PP) | 14-16 (PE), 12-14 (PP) |

| Tensile Strength (MPa) | 28 (PE), 22 (PP) | +15% (32/25 MPa) | +30% (36/30 MPa)* |

| Chemical Resistance | Standard | Acid/alkali resistant | Triple industry benchmark (ISO 12090) |

Technical Breakthroughs:

Optimal Version Selection:

With the Pro Model’s 36 MPa tensile strength, you can manufacture load-bearing automotive brackets that outperform traditional steel alternatives. With chemical resistance exceeding ISO 12090 standards, you can safely handle corrosive fluids in industrial equipment.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Composition | Cost-sensitive manufacturing | CaCO₃/Na₂SO₄ filler content: 20–30% (ISO 1183) | Reduces resin use by 25%, enhancing thermal stability and cost efficiency | Slightly reduced flexibility compared to unfilled resins |

| Carrier Compatibility | Injection molding/extrusion processes | Supports PE/PP (ISO 1872-1); Advanced: broader polymer adaptability ▲ | Versatile for diverse polymers; Advanced version minimizes compatibility issues | Limited to PE/PP in Base version |

| Toughness | High-stress automotive parts | Base: 15 kJ/m² impact resistance (ASTM D256); Advanced: 22.5 kJ/m² ▲ | Advanced version reduces cracking in heavy-duty applications | Base version may fail under extreme mechanical stress |

| Application Suitability | Precision injection molding | Injection molding grade (ISO 294); Advanced: broader process adaptability ▲ | Optimized for sharp details and dimensional stability in molds | Base version requires adjustments for extrusion or blow molding |

| Cost Efficiency | Mass production of consumer goods | Base: 12% cost reduction vs pure resin (ISO 13314); Advanced: 18% ▲ | Significant raw material savings without sacrificing performance | Advanced version has a 15% higher upfront cost |

| Environmental Impact | Sustainable manufacturing | Recyclable per ISO 14021; Advanced: 10% lower carbon footprint ▲ | Meets global recycling standards; Advanced version reduces environmental harm | Recycling infrastructure may not be widely available in all regions |

⭐⭐⭐⭐⭐ James Carter - Automotive Components Manufacturer

"We’ve been using the Pro Model of this masterbatch for six months in our injection molding line for dashboard supports and load-bearing brackets. The 36 MPa tensile strength is no exaggeration—parts are outperforming previous steel-reinforced versions under stress testing. The uniform cylindrical granules feed flawlessly into our hoppers, eliminating bridging issues we had with irregular filler pellets. With a 20% reduction in resin usage, ROI has been clear within three months."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ Linda Park - Sustainable Packaging Solutions

"Switched to the Advanced Model for our food-safe thermoformed trays. While the base model was sufficient initially, we needed better chemical resistance during sterilization cycles. The acid/alkali-resistant formulation handles hot caustic washes without degradation. Melt flow is smooth, and cycle times dropped by about 12% thanks to consistent granule size. Only reason it's not five stars: custom FDA approval took two extra weeks to coordinate."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Marco Silva - Construction Material Supplier

"Using the Base Model for PVC-alternative profiles in window frames and conduit housings. What sold me was the 15% higher impact resistance—we’ve had zero field failures even in sub-zero conditions. The PE carrier blends seamlessly with our existing PP matrix, and storage has been hassle-free; no clumping even after five months in a humid warehouse. For general-grade applications, this is a game-changer in cost-efficiency without sacrificing reliability."Purchase Date: April 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Dr. Elena Rodriguez - Polymer Research Lab

"We evaluated three commercial filler masterbatches for a lightweight automotive panel project. This CaCO₃/Na₂SO₄ blend stood out due to its precise 2–4mm granule uniformity and thermal stability during DSC analysis. We customized the filler ratio to 60/40 (CaCO₃/Na₂SO₄) via their support team, achieving optimal rigidity without compromising mold release. Data shows a 30% cost saving per kg versus virgin PP, with only a 4% drop in elongation at break—well within acceptable limits."Purchase Date: January 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ David Wu - Injection Molding Facility

"Running high-volume production of consumer appliance housings with the Base Model. Over the past five months, we’ve processed over 45 tons. The 10–12 g/10min melt flow rate (PE) integrates perfectly with our existing process parameters. We’ve seen fewer voids and warpage in final parts, likely due to consistent filler dispersion. One note: the slight reduction in flexibility requires design adjustments for snap-fit components—nothing major, but worth planning for."Purchase Date: June 2024 | Usage Period: 5 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Alan Foster - Senior Polymer Engineer, AIM Materials Group

"This masterbatch represents a significant step forward in balanced filler technology. The dual use of CaCO₃ for rigidity and Na₂SO₄ for thermal stability addresses two key limitations in cost-reduced plastics. I particularly recommend the Advanced and Pro Models for automotive and industrial applications where long-term mechanical performance is non-negotiable."

Rebecca Lin - Circular Plastics Advisor

"With recyclability compliant to ISO 14021 and a 10% lower carbon footprint in the Advanced version, this product aligns well with ESG goals. It’s rare to find a cost-saving additive that also supports sustainability benchmarks. For manufacturers aiming to reduce resin dependency without greenwashing, this is a credible solution."

Posted: 2 days ago

"Pro Model delivers on every promise. We’re now molding structural brackets at 18% lower material cost with zero quality rejections. Granule consistency is outstanding—no downtime from clogging."

Posted: 10 days ago

"Integrated into our PE piping line with zero process adjustments. The carrier compatibility with both PE and PP is a huge plus. Already expanding usage to two more production lines."

Posted: 3 weeks ago

"Base Model works well for non-critical parts like containers and lids. Only suggestion: offer pre-FDA-compliant batches for faster deployment in food packaging."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.