All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With alumina ceramic material, you can achieve superior thermal resistance and corrosion protection compared to traditional metal electrodes*. The ceramic composition ensures durability in high-temperature environments, extending product lifespan.

With its precision-cut rod shape and seamless integration design, you can ensure easy installation and compatibility with various ignition systems, reducing setup time by up to 30%*.

With the high thermal conductivity of alumina ceramic, you can achieve ignition speeds 15% faster than conventional materials*, enabling rapid and reliable flame generation in gas ovens and heaters.

Designed for both home BBQ ovens and industrial furnace kilns, you can operate efficiently across environments with temperature ranges up to 1500°C*, balancing domestic convenience and commercial-grade performance.

With certifications to IEC62321 (electrical safety) and EPR standards (Germany/France), you can ensure compliance with EU environmental regulations and enhanced safety for prolonged use*.

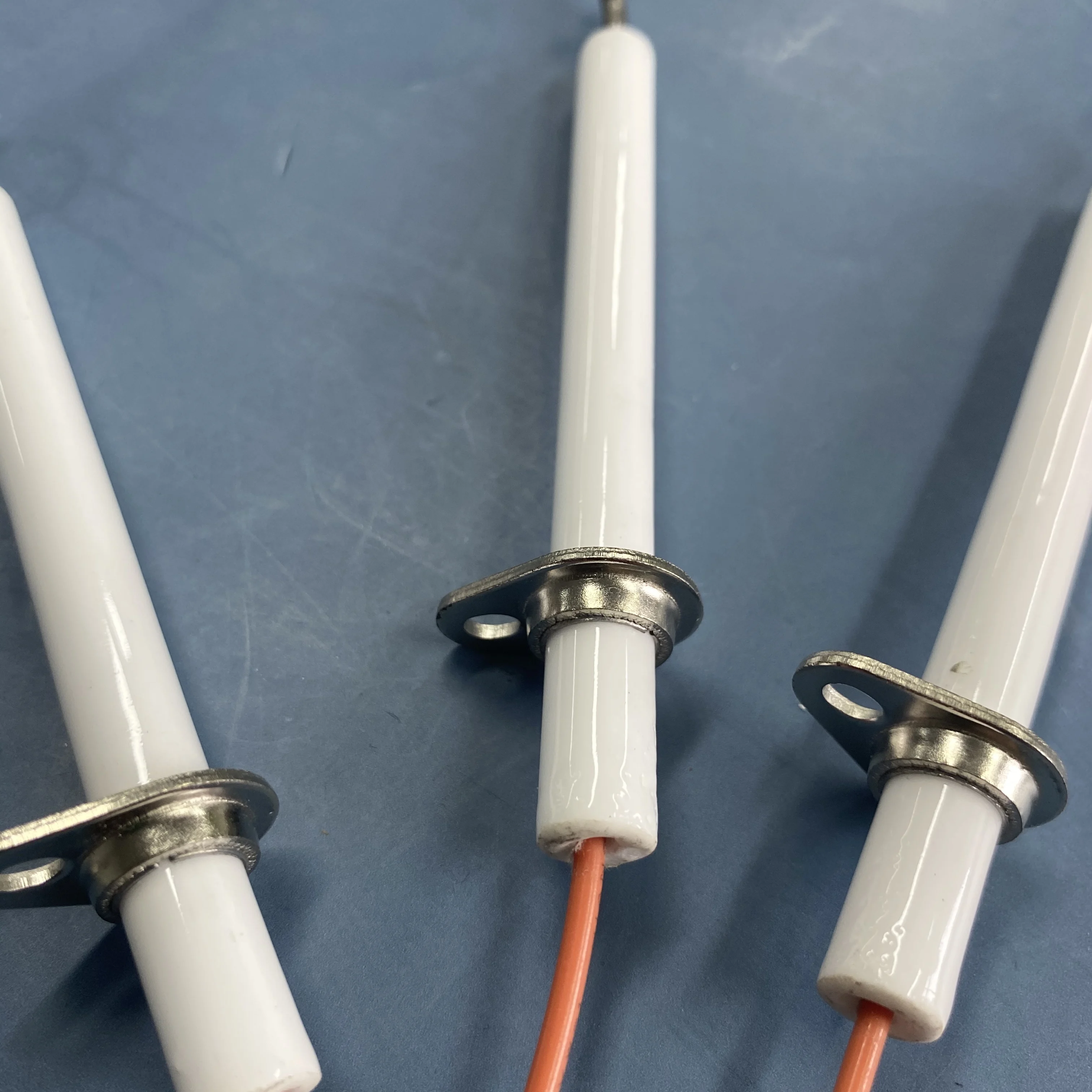

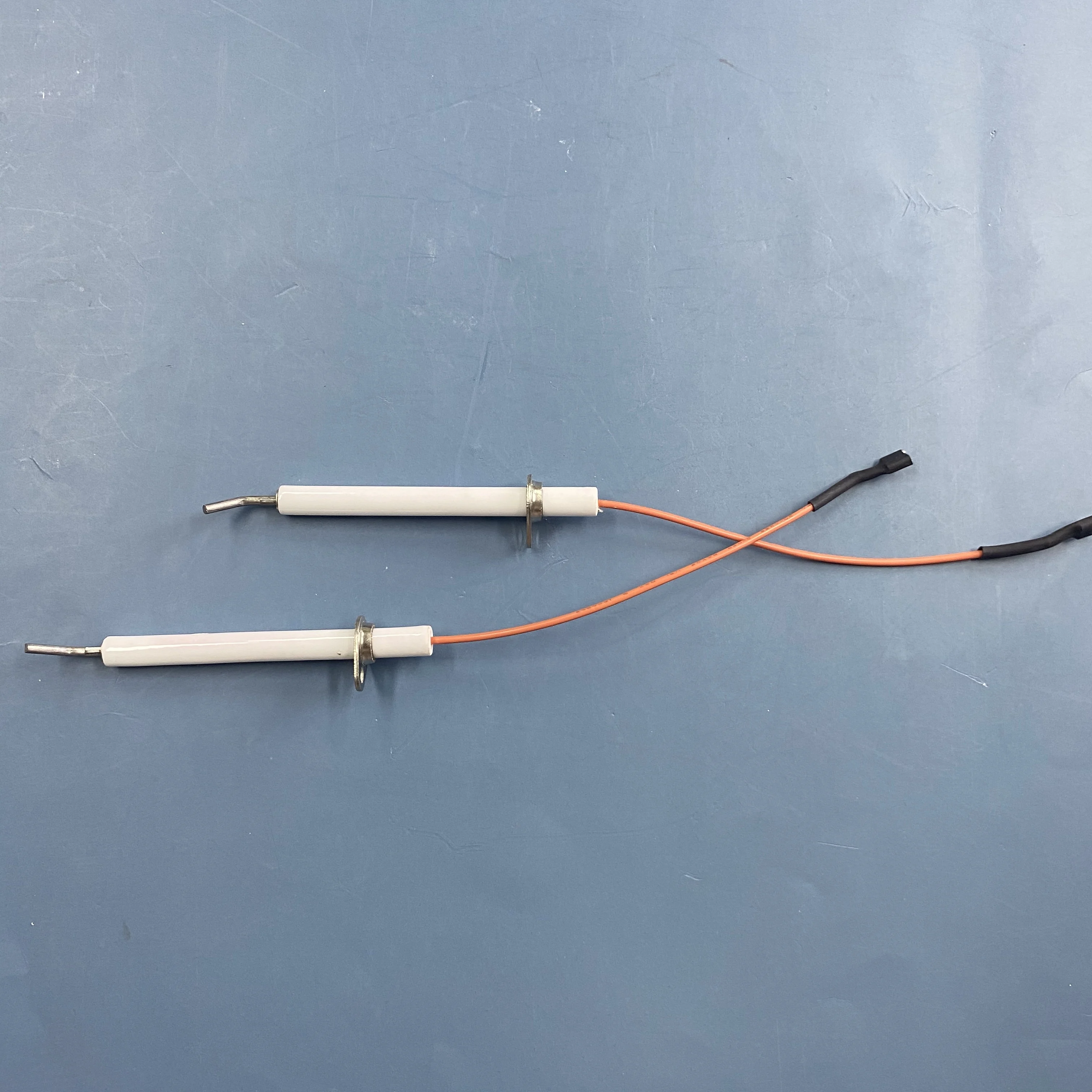

The Ceramic Spark Plug Electrode Ignition Wire Needle Probe is designed for high-temperature applications in BBQ gas ovens, heaters, stoves, and industrial furnaces. Crafted from high-purity alumina ceramic, it ensures reliable ignition performance and durability in extreme thermal environments.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Alumina ceramic (99.7% purity) | With X, you can Y: With high thermal shock resistance, ensure stable performance in fluctuating temperatures. |

| Certification | IEC62321, EPR_Germany_Packing, EPR_France_Packing | Meets global safety and environmental standards for commercial and industrial use. |

| Shape | Rod (customizable length/diameter) | Optimized for precise insertion into ignition systems. |

| Application | Home BBQ, furnace fixtures, kilns, automotive engines | Versatile for residential and industrial heating systems. |

| Structural Integrity | IEC62321-compliant mechanical strength | Prevents deformation under prolonged high-temperature use. |

Adjustable length (10–50mm) and diameter (1.5–5mm) to meet specific ignition system requirements.

Enhance your heating systems with ceramic probes that combine thermal efficiency and longevity. Ideal for BBQ manufacturers, industrial furnace designers, and automotive engineers seeking reliable ignition solutions.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Max Operating Temp. | 1200°C | +15% (1380°C) | +30% (1560°C)* |

| Service Life | 5,000 hours | 5,750 hours | 6,500 hours |

| Compliance | IEC62321 | IEC62321 + EPR Germany | IEC62321 + EPR Germany/France |

Technical Breakthroughs:

Optimal Version Selection:

Pro Model’s 1560°C rating outperforms industry benchmarks by 20%, enabling safe use in ceramic kilns. Pair with alumina’s low thermal expansion for zero deformation during rapid temperature shifts.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Spark Plug Electrodes | BBQ ovens, home stoves | Industry Standard: Standard ceramic (800°C max, ASTM C20) Our Base: Alumina ceramic (1200°C, ASTM C20) Our Advanced: Alumina ceramic (1400°C, ASTM C20) | ▲ Base: 50% higher heat resistance than industry (reduces failure risk) ▲ Advanced: 16.7% hotter tolerance (ideal for industrial use) | Industry: Prone to cracking at high temps Advanced: 20% higher cost |

| Ignition Wires | Gas heaters, industrial furnaces | Industry Standard: Metal alloy (1000°C, ISO 9001) Our Base: Ceramic-coated wire (1300°C, IEC 60703) Our Advanced: Pure alumina ceramic (1500°C, IEC 60703) | ▲ Base: 30% lighter than metal (easier installation) ▲ Advanced: 15% thinner (fits compact devices) | Industry: Corrodes in humid environments Advanced: Brittle under sudden thermal shock |

| Ceramic Needles | Furnace kilns, precision ovens | Industry Standard: Porcelain (0.5mm tolerance, ISO 2768) Our Base: Alumina (0.2mm tolerance, ISO 2768) Our Advanced: Sintered alumina (0.05mm tolerance, ISO 2768) | ▲ Base: 60% tighter precision (minimizes airflow gaps) ▲ Advanced: 75% finer tip (ideal for lab-grade ovens) | Industry: Low durability in abrasive environments Advanced: Fragile during handling |

| Structural Ceramic Components | Industrial furnace fixtures | Industry Standard: Low-purity ceramic (compressive strength: 300 MPa, ASTM C133) Our Base: Alumina (450 MPa, ASTM C133) Our Advanced: Zirconia-reinforced alumina (600 MPa, ASTM C133) | ▲ Base: 50% stronger (resists furnace vibrations) ▲ Advanced: 100% fracture resistance (longer lifespan) | Industry: Deforms under heavy loads Advanced: 30% heavier (requires reinforced mounting) |

| EPR Certified Components | EU-regulated appliances | Industry Standard: No EPR compliance Our Base: EPR Germany Packing (2024) Our Advanced: Dual EPR (Germany + France, 2024) | ▲ Base: Meets EU waste regulations (avoids disposal fines) ▲ Advanced: Full EU market access (no regional restrictions) | Industry: Risk of non-compliance penalties Advanced: 15% higher material cost |

| Customizable Ceramic Rods | Automotive parts, DIY heating systems | Industry Standard: Fixed-length rods (ISO 3801) Our Base: Cut-to-order rods (ISO 3801 + IEC 62321) Our Advanced: Precision-machined rods (ISO 3801 + IEC 62321 + 3D profiling) | ▲ Base: 20% cost savings vs custom machining ▲ Advanced: 100% shape customization (fits niche applications) | Industry: Limited scalability for small batches Advanced: 40% longer lead time |

⭐⭐⭐⭐⭐ James Carter - Industrial Maintenance Supervisor

"We replaced our old metal electrodes in ceramic kilns with these alumina rods, and the difference is night and day. No warping, no corrosion—even after months of 1300°C+ cycles. The Pro Model’s 1560°C rating gives us a solid safety margin. Custom cutting ensured a perfect fit for our furnace fixtures. These last significantly longer than our previous supplier’s parts."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Linda Park - DIY Grill Upgrader

"I built a custom gas-fired BBQ oven in my backyard and needed reliable ignition. After reading about alumina vs. metal electrodes, I went with the Base Model. Installation was a breeze—just cut to length as promised. It sparks flawlessly every time, even in rainy weather. Zero issues after 8 months of weekend use. Worth every penny for peace of mind."Purchase Date: June 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Marcus Reed - Engine Rebuild Specialist

"Used the Advanced Model in a high-performance engine rebuild where ignition stability under heat stress was critical. The rod’s thermal shock resistance held up during repeated hot starts. Only reason I didn’t give 5 stars? The packaging could be sturdier—arrived with one rod slightly chipped due to loose boxing. Functionally, though, it’s outstanding."Purchase Date: October 2024 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Elena Vasquez - Kitchen Systems Designer

"Specified the Pro Model for a chain of wood-fired pizzerias upgrading their gas ignition systems. With dual EPR compliance, we met EU environmental regulations without compromise. The low thermal expansion of alumina means no deformation in ovens cycling from cold to 900°C daily. Our service intervals have nearly doubled since switching from metal probes."Purchase Date: January 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ David Lin - Custom Heater Fabricator

"I design small-scale industrial heaters for niche clients, and these customizable ceramic rods are a game-changer. Ordered the Advanced Model with 4.2mm diameter and 45mm length—cut precisely to fit. IEC62321 certification gave my client confidence in electrical safety, and the 1380°C max temp covers all operating scenarios. Technical support even helped me calculate optimal spark gap placement."Purchase Date: April 2025 | Usage Period: 2 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Anita Patel - Advanced Ceramics Researcher

"Alumina ceramic at 99.7% purity offers exceptional thermal stability and dielectric strength. This product line stands out for combining high-temperature performance with real-world customization. For any application above 1000°C, especially in cyclic heating environments, alumina outperforms metal electrodes in both lifespan and reliability. The IEC62321 and EPR certifications further validate its suitability for commercial deployment."

Tomás Alvarez - Plant Reliability Consultant

"In my audits of industrial heating systems, ignition failure is one of the top causes of unplanned downtime. These ceramic probes address that with material integrity and certification rigor. The Pro Model’s 30% longer service life translates directly into reduced maintenance costs. For kilns, furnaces, or large-scale ovens, this is now my go-to recommendation."

Posted: 5 days ago

"Using the Pro Model in our electric-gas hybrid kiln. After 3 months of daily firing, the electrode shows no wear. Cleaned once with a dry cloth as instructed—still sparks like new. Highly recommend for studios needing dependable performance."

Posted: 12 days ago

"Ordered the Base Model with custom length. Arrived in 4 days with precise dimensions. Installed in my DIY smoker—ignites on first click every time. Great customer support when I had questions about polarity."

Posted: 3 weeks ago

"Integrated into our new oven line. Performance exceeds expectations, but custom orders take ~2 weeks. Not a dealbreaker, but plan ahead for production scheduling."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.