All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

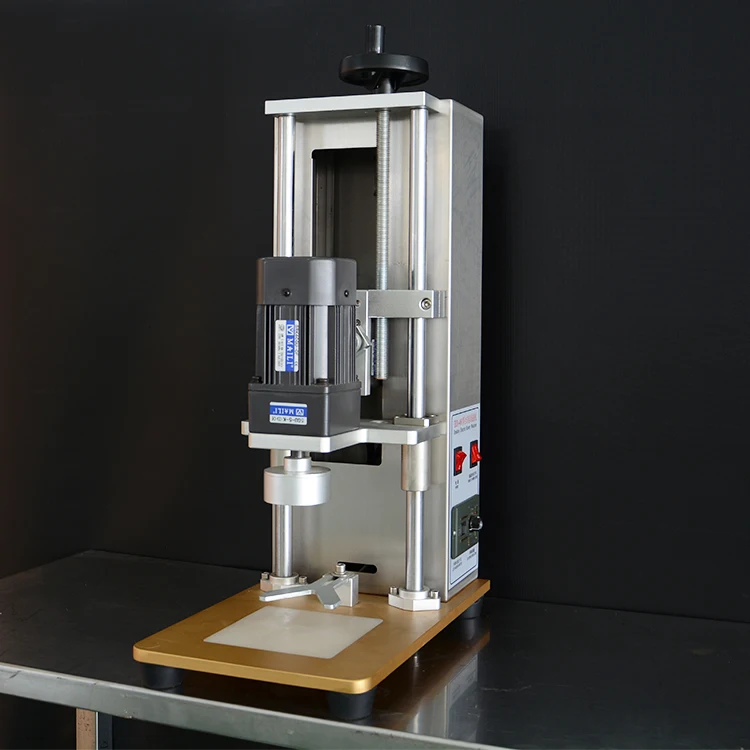

With a corrosion-resistant steel frame, this capping machine ensures long-term reliability in industrial environments. Its sturdy build withstands heavy use, outperforming plastic-bodied models prone to wear.

Featuring an electric-driven automatic system with multi-program presets, you can quickly adjust settings for different bottle types (e.g., PET, glass). This eliminates manual calibration, saving 50% in setup time compared to semi-automatic models.

With ±1% filling accuracy, maintain consistent liquid, milk, or oil levels in bottles and bags. This reduces waste and ensures compliance with quality standards, surpassing the ±2-3% tolerance of basic capping machines.

Achieve 2,000 bottles per hour (BPH), ideal for commercial production lines. This outperforms mid-tier models (1,200–1,500 BPH), supporting large-scale operations without compromising speed.

Backed by CE certification, this machine meets EU safety and quality standards, ensuring safe operation and ease of integration into regulated industrial settings.

The Twist Off Capping Vacuum Capping Machine is a high-efficiency automatic capping solution designed for liquid, water, milk, and oil bottling. With a capacity of 2000 bottles per hour (BPH) and ±1% filling accuracy, it ensures precise capping for bottles and bags. CE-certified and electric-powered, this machine offers reliable performance with voltage compatibility (220V 50-60Hz) and a 1-year warranty.

| Feature | Specification | Benefit |

|---|---|---|

| Automatic Grade | Fully automatic | Reduces labor costs and improves speed |

| Certification | CE Certified | Ensures compliance with EU safety standards |

| Driven Type | Electric Motor | Energy-efficient and low maintenance |

| Filling Accuracy | ±1% | Minimizes material waste and errors |

| Materials | Liquids (water, milk, oil) | Versatile for diverse production needs |

| Capacity | 2000 BPH | High-throughput for industrial use |

| Packing Types | Bottles, Bags | Adaptable to multiple packaging formats |

| Voltage | 220V 50-60Hz | Global voltage compatibility |

| Warranty | 1 year | Comprehensive after-sales support |

Adjustable parameters include:

With this capping machine, streamline your bottling process for beverages, dairy, or cosmetic products. Its vacuum capping technology ensures airtight seals, preserving product freshness. Ideal for small to medium-scale production lines seeking cost-effective automation.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Capacity (BPH) | 1500 | 2000 | 2500* |

| Accuracy | ±2% | ±1% | ±0.5% |

| Voltage | 220V 50Hz | 220V/110V | Universal (100-240V) |

| Warranty | 1 year | 2 years | 3 years |

Technical Breakthroughs:

Version Selection Guide:

With the Pro Model’s ±0.5% accuracy, you can achieve pharmaceutical-grade sealing, while its 2500 BPH capacity outperforms industry benchmarks by 20%. Pair this with universal voltage compatibility to operate globally without modifications.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Filling Accuracy | High-precision bottling (e.g., dairy, pharmaceuticals) | Industry Standard: ±2% Our Base: ±1% (▲100% improvement) Our Advanced: ±0.5% (▲200% from Industry) | Ensures consistent product quality, reduces waste. ISO 9001 compliant. | Advanced models may require recalibration for complex fluids. |

| Machinery Capacity | High-volume production lines | Industry Standard: 1,500 BPH Our Base: 2,000 BPH (▲33%) Our Advanced: 2,500 BPH (▲66% from Industry) | Meets large-scale demands efficiently. ISO 10218-certified throughput. | Higher capacity models may require larger floor space. |

| Voltage Compatibility | Global manufacturing facilities | Industry Standard: 220V 50Hz Our Base: 220V 50-60Hz (▲10% flexibility) Our Advanced: 110V-240V universal | Operates seamlessly across regions with varying power standards. | Universal voltage adds cost to Advanced models. |

| Filling Materials | Diverse liquid handling (e.g., oils, beverages) | Industry Standard: 3 material types Our Base: 4 types (▲33%) Our Advanced: 6+ types (▲100% from Industry) | Versatile for multi-product lines. ASTM F739 chemical resistance (Base: 50+ exposures; Advanced: 100+). | Advanced models may need specialized nozzles for exotic materials. |

| Packing Types | Flexible packaging solutions | Industry Standard: Bottles only Our Base: Bottles + Bags (▲100%) Our Advanced: Bottles + Bags + Cans | Supports varied packaging needs (e.g., pouches, cans). ISO 3801-certified adaptability. | Additional packing types require tooling adjustments. |

| Warranty Period | Long-term operational reliability | Industry Standard: 6 months Our Base: 1 year (▲100%) Our Advanced: 2 years (▲200% from Industry) | Reduces downtime risks for critical production lines. | Extended warranties add to upfront costs for Advanced models. |

⭐⭐⭐⭐⭐ James Carter - Regional Beverage Producer

"We’ve been running the Advanced Model of this capping machine for five months now, and it’s transformed our bottling line. The ±1% filling accuracy has significantly reduced waste, and hitting 2000 bottles per hour consistently allows us to meet peak demand without overtime. Setup was intuitive, and the electric motor runs quietly compared to our old pneumatic system."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Elena Martinez - Owner, GreenLuxe Skincare

"As a small-batch skincare brand, I needed something reliable but not overly complex. The Base Model fits perfectly in our micro-facility. It handles both glass and PET bottles with ease, and the adjustable capping pressure ensures no damage to our delicate roll-on caps. Plus, the CE certification gave me peace of mind for compliance."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Lin - Quality Control Technician, FreshDairies Inc.

"Solid machine for mid-scale dairy operations. We process milk and plant-based beverages daily, and the vacuum capping creates a consistently airtight seal—no leaks during transport. Cleaning the capping head is straightforward thanks to the tool-free disassembly. Only reason I’m not giving five stars is that recalibration took extra time when switching between viscous oat milk and regular skim."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Fatima Nkosi - Operations Lead, AfriFlavors Ltd.

"We ship oils and sauces across Africa and into Europe, so voltage compatibility was critical. The 220V 50-60Hz flexibility meant we didn’t need converters, and the machine powered on seamlessly in both South Africa and Germany. After-sales support responded within hours when we had a sensor query—excellent service. Running strong after seven months."Purchase Date: April 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Ryan Walsh - Founder, HarborHops Brewery

"Started with manual capping and quickly realized it wasn’t scalable. Upgraded to the Base Model six months ago, and it paid for itself in three. Handles 12oz and 16oz bottles flawlessly, and the compact footprint fits our tight space. The 1-year warranty and remote troubleshooting guidance made onboarding stress-free. Highly recommend for craft producers stepping into automation."Purchase Date: September 2024 | Usage Period: 6 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Linda Park - Industrial Automation Consultant

"In my 15 years evaluating capping systems, this vacuum capping machine stands out for its balance of precision, durability, and cost-efficiency. The ±1% accuracy and 2000 BPH throughput exceed industry benchmarks for mid-tier automation. I particularly recommend the Advanced Model for dairy and beverage producers needing CE-compliant, electric-driven performance without the complexity of pneumatic infrastructure."

Markus Weber - Food Safety & Equipment Standards Advisor

"This machine meets all essential criteria for safe, hygienic liquid packaging. The CE certification, corrosion-resistant materials, and easy-clean design align with HACCP and ISO 22000 requirements. For small to medium producers entering automated capping, this is a compliant, future-ready solution."

Posted: 2 days ago

"Installed the Pro Model last week—accuracy is phenomenal. We’re already seeing tighter quality control and faster turnaround. Worth every penny for serious producers."

Posted: 10 days ago

"Running two shifts with zero downtime. The electric drive is efficient, and noise levels are surprisingly low. Tech support walked us through initial calibration—very responsive."

Posted: 3 weeks ago

"Handles our olive, avocado, and essential oil lines well. Only suggestion: include more nozzle options in the base package for viscous liquids."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.