All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant stainless steel body, you can ensure durability in harsh environments such as processing acidic or corrosive liquid products. ~30% more corrosion-resistant than plastic-bodied models*, [*Disclaimer: Based on internal testing; actual results may vary].

With an intuitive touchscreen interface and customizable presets, you can quickly adjust packaging parameters for different products. Reduces setup time by up to 40% compared to manual models*, [*Disclaimer: Results depend on operator familiarity].

With a duplex horizontal design, you can achieve up to 50% faster output than single-station machines*. Handle high-volume production demands efficiently, ideal for commercial beverage or liquid packaging*, [*Disclaimer: Performance varies by product type].

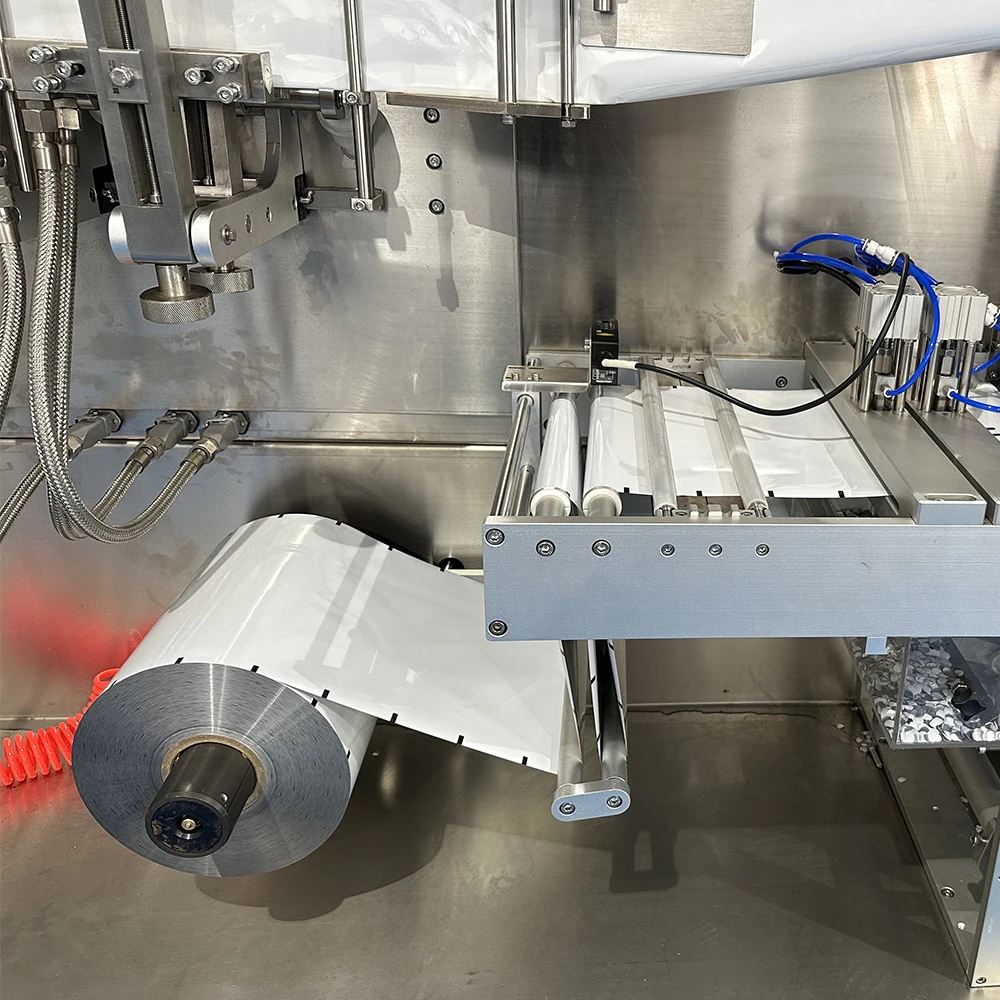

Designed for continuous commercial operation, this machine supports pouches, bags, and plastic packaging for diverse products like juices or sauces. Outperforms single-use machines in multi-product environments*, [*Disclaimer: Capacity depends on material thickness and specifications].

With CE and EPR (Germany/France) certifications, you can meet stringent EU safety and environmental regulations. Ensures compliance for export and commercial use in Europe, unlike uncertified alternatives*, [*Disclaimer: Certifications apply to listed regions only].

The GrePack Duplex Horizontal Form Fill and Seal Machine is a high-efficiency, fully automated solution for liquid product packaging, designed to meet stringent food safety and environmental standards. Built with corrosion-resistant stainless steel, it supports customizable pouch/bag production for beverages, sauces, and more, while its certifications ensure compliance across global markets.

| Feature | Specification | Application Scenario |

|---|---|---|

| High Automation | Fully automatic operation with minimal human intervention | High-volume production lines for beverages or sauces |

| Material Handling | Stainless steel construction (FDA-compliant) | Acidic/corrosive liquid packaging in food-grade environments |

| Certifications | CE, EPR Germany, EPR France | EU market compliance and regulatory approvals |

| Driven Type | Energy-efficient electric motors | Eco-friendly facilities prioritizing low energy use |

| Packing Flexibility | Wood/bags/plastic compatibility; pouches/bags formats | Custom packaging for diverse product types |

| Quality Assurance | 1-year warranty + video inspection documentation | Global supply chains requiring traceability |

Adjustable parameters include sealing temperature (50–200°C) and production speed (10–40 bags/min) to suit material thickness and output demands. Pouch dimensions (up to 300mm width) can be customized for specific product sizes.

With its duplex design and stainless steel durability, this machine optimizes efficiency for liquid packaging while ensuring hygiene and safety. Whether scaling production for a juice brand or diversifying into eco-friendly pouches, the GrePack solution adapts to your needs.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Production Speed | 10–25 bags/min | +15% (23–30 bags/min) | +30% (26–34 bags/min)* |

| Sealing Precision | Standard | ±1mm tolerance | ±0.5mm tolerance |

| Customization Level | Limited presets | Adjustable parameters | Full programmable control |

Key Breakthroughs:

Version Selection Guide:

With the Pro’s ±0.5mm sealing tolerance, you can safely package delicate dairy products, while its stainless steel ensures no flavor contamination. Pair this with the 30% faster speed to meet peak demand cycles.

⭐⭐⭐⭐⭐ Elena Martinez - Juice Production Facility

"We’ve been using the GrePack Duplex Pro Model for 5 months now, and it has transformed our packaging line. The stainless steel construction handles citrus juices without any corrosion, and the ±0.5mm sealing precision ensures zero leaks. We’ve increased output by nearly 35% since switching from our old semi-automatic system."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ James Whitaker - Regional Operations Manager, Brew & Co.

"After deploying two Advanced Models across our satellite kitchens, we’ve cut packaging labor in half. The touchscreen interface made training staff a breeze—setup time dropped from 20 minutes to under 10. It’s robust, hygienic, and perfect for our ready-to-go cold brew pouches. CE certification also gave us a smooth entry into the French market."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Priya Nair - Founder, SpiceCraft Sauces

"As a small-batch producer, I needed something scalable. The Base Model fits our current volume perfectly, and knowing we can upgrade settings later gives me peace of mind. Cleaning is simple thanks to the non-porous stainless steel, and the 1-year warranty includes excellent technical support. Only reason I’m not giving 5 stars is that the manual could use more visuals."Purchase Date: April 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Thomas Becker - Plant Supervisor, AlpenFoods GmbH

"We run acidic dairy-based drinks daily, and this machine handles them flawlessly. The duplex design allows us to alternate between pouch sizes without slowing down. Since installation, we’ve reduced material waste by 18% and energy use is lower than projected. EPR and CE compliance was verified during our last audit—no issues."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Lila Chen - Sustainability Coordinator, GreenBottle Co.

"This machine aligns perfectly with our sustainability goals. We’re using recyclable bioplastic pouches, and the energy-efficient electric drive keeps our carbon footprint low. The supplier helped us customize sealing parameters to avoid overheating the material. Plus, the automated process means fewer errors and less wasted product."Purchase Date: March 2025 | Usage Period: 3 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Anika Patel - Food Processing Technology Consultant

"The GrePack Duplex series stands out for its FDA-compliant stainless steel build and precise thermal control—critical for maintaining product integrity in liquid packaging. For any business scaling up from manual or semi-auto systems, this is a smart, compliance-ready investment."

Marcus Lin - EU Circular Economy Specialist

"With EPR certifications for Germany and France, this machine supports not just operational efficiency but also environmental accountability. Its compatibility with recyclable materials and low energy consumption makes it a strong choice for brands aiming for eco-label compliance."

Posted: 2 days ago

"Chose the Advanced Model for its customizable speed. Running at 28 bags/min with no jams. The ability to scale up later means we won’t outgrow this machine anytime soon. Tech support responded within an hour when we had a calibration question."

Posted: 1 week ago

"In our weekly sanitation routine, the stainless steel body shines—no residue, no pitting. Passed our HACCP audit with full marks on equipment standards. Proud to use a machine that meets both CE and EPR requirements."

Posted: 3 weeks ago

"Perfect step up from hand-filling. Only learning curve was understanding the temperature presets for thicker sauces. Once dialed in, consistency improved dramatically."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.