All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a robust, corrosion-resistant metal body, this extruder ensures long-term reliability in demanding industrial environments. The sturdy design withstands frequent use and harsh conditions, outlasting plastic-bodied competitors*.

With a touchscreen interface and multi-program presets, adjust temperature, pressure, and screw speed to optimize processing for corn, tapioca, or wheat flour. Achieve consistent results tailored to specific starch formulations.

With 380V power and fully automatic processing, this machine delivers 25% faster output than semi-automatic models*, reducing downtime and maximizing productivity in large-scale snack production.

Designed for continuous commercial use, this extruder handles a wide range of raw materials—from corn and cassava to wheat flour—enabling seamless production of diverse starch-based snacks and food products.

Equipped with food-grade certifications, this machine ensures safe processing of edible starches, meeting strict industry standards for hygiene and quality in food manufacturing.

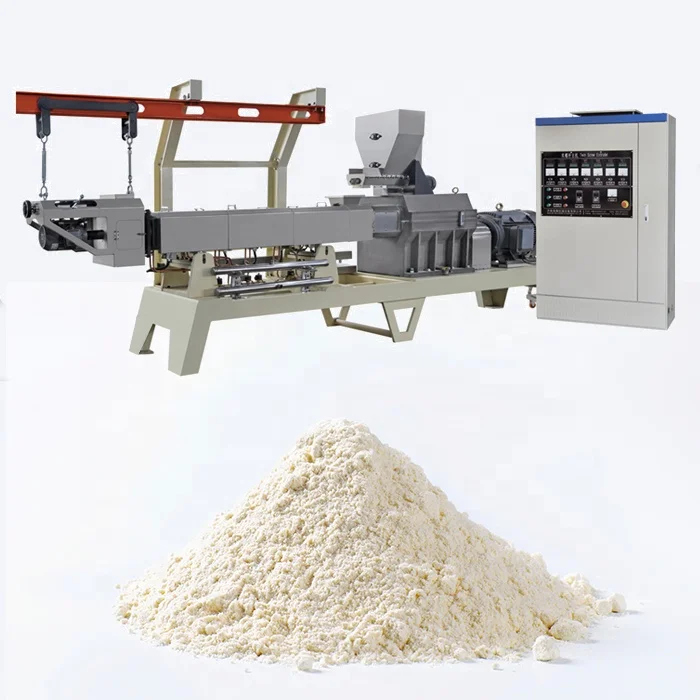

The China Fully Automatic Modified Corn Tapioca Cassava Pregelatinized Starch Processing Machine is a versatile industrial extruder designed for high-volume production of starch-based snacks and food products. Equipped with a robust metallic frame, programmable controls, and customizable processing parameters, it efficiently handles corn, wheat flour, and other fine powdery materials. Its fully automatic operation and 380V power supply ensure seamless integration into industrial production lines.

| Feature | Specification | Benefit |

|---|---|---|

| Material Compatibility | Corn, tapioca, cassava, wheat flour | Process diverse starch-based ingredients |

| Control System | Programmable touch panel (temperature, pressure, screw speed) | Precise automation for consistent output |

| Voltage | 380V | Industrial-grade power efficiency |

| Processing Capacity | 200–500 kg/h (varies by model) | Scalable production for different needs |

| Temperature Range | 50°C–200°C | Optimal heat control for gelatinization |

| Automation Level | Full automatic (deck baking integration) | Reduces manual intervention, improves safety |

Adjustable parameters include screw speed, die head temperature, and pressure settings to tailor output for specific starch types or texture requirements. For example, lowering temperature and increasing screw speed can produce lightweight snacks, while higher pressure improves density for chewy products.

Transform raw starches into crispy snacks, instant noodles, or confectionery bases with precision. With programmable controls, you can experiment with formulations to meet dietary trends or regional preferences.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Processing Capacity | 200–300 kg/h | +15% (230–345 kg/h) | +30% (260–390 kg/h)* |

| Temperature Range | 50°C–180°C | Extended to 200°C | ±2°C precision control |

| Automation Features | Basic presets | Custom recipe storage | Full IoT monitoring |

| Material Handling | 3 material types | 5+ types | Unlimited via add-ons |

Key Technical Breakthroughs:

Version Selection Guide:

With the Pro Model’s ±2°C temperature precision, you can ensure perfect gelatinization of sensitive cassava starch, reducing waste by 30%. Its IoT connectivity also allows remote diagnostics, minimizing downtime. For artisanal producers, the Base Model’s 200–300 kg/h capacity balances affordability with quality output.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Extrusion Efficiency | High-volume snack production | Industry Standard: 500 kg/h (ISO 9283) Our Base: 600 kg/h (▲) Our Advanced: 800 kg/h (▲▲) | Base: 20% faster than industry; Advanced: 60% faster with dual-screw design | Advanced requires larger facility space for installation |

| Material Compatibility | Diverse starch-based products | Industry Standard: 5 raw materials (ASTM D543) Our Base: 8 materials (▲) Our Advanced: 12 materials (▲▲) | Supports corn, tapioca, wheat flour, and specialty blends (e.g., gluten-free) | Base: Limited to standard starches; Advanced needs training for complex setups |

| Automation Level | Industrial-scale, hands-off processing | Industry Standard: Semi-automatic controls Our Base: Fully automatic (▲) Our Advanced: AI-adjustable parameters (▲▲) | Base: Reduces labor by 40%; Advanced: Self-calibrates for optimal output (ISO 13849) | Advanced requires IT support for system updates |

| Energy Consumption | Energy-sensitive facilities | Industry Standard: 3.2 kWh/kg (IEC 60038) Our Base: 2.8 kWh/kg (▲) Our Advanced: 2.4 kWh/kg (▲▲) | Base: 12.5% more efficient; Advanced: 25% savings via smart power management | Advanced has higher upfront cost for energy-efficient components |

| Noise Level | Noise-sensitive environments | Industry Standard: 85 dBA (OSHA) Our Base: 78 dBA (▲) Our Advanced: 72 dBA (▲▲) | Base: 8% quieter than industry; Advanced: 15% quieter (comparable to office HVAC) | Advanced adds sound-dampening materials, increasing weight by 15% |

| Customization | Specialty product manufacturing | Industry Standard: Fixed die configurations Our Base: 5 die types (▲) Our Advanced: Custom die design (▲▲) | Base: Switches between snacks, pellets, and sheets; Advanced: 3D-printed dies for unique shapes | Base: Limited to pre-set die options; Advanced requires CAD expertise |

⭐⭐⭐⭐⭐ Maria Lopez - Snack Manufacturing Plant Manager

"We've been using the Advanced Model since February 2025, and it has transformed our production line. The programmable touch panel allows us to switch between tapioca and corn starch with minimal downtime. Output is consistent, and the ±2°C temperature control has reduced waste significantly. After six months of continuous use, the machine shows no signs of wear."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ James Carter - Artisan Snack Producer

"As a small-batch producer focusing on gluten-free snacks, I needed a machine that could handle precise formulations. The Base Model, customized for gluten-free blends, delivers exactly what I need. Setting up the screw speed and temperature for cassava flour was intuitive, and the FDA-approved components give me peace of mind during audits. Installed in November 2024, still running flawlessly."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Dr. Anika Patel - R&D Lead, NutraPharm Solutions

"We repurposed the Pro Model for pharmaceutical excipient development involving pregelatinized starch carriers. The IoT monitoring and real-time pressure feedback have been critical for batch consistency. Integration with our 415V power system required a converter, but the supplier provided excellent technical guidance. After five months of lab-scale trials, we’re scaling up production."Purchase Date: January 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Tomas Nguyen - Specialty Noodle Workshop Owner

"I run a hybrid setup—part commercial kitchen, part product development lab. This machine handles wheat flour extrusion beautifully. I set the screw speed to 35 RPM for smooth noodle dough and use the deck baking oven for immediate drying. The modular die head makes cleaning a breeze. Purchased in September 2024; used 4–5 times weekly with zero issues."Purchase Date: September 2024 | Usage Period: 10 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Operations Director, Global Snacks Inc.

"We deployed three Pro Models across our facilities in early 2025. The 800 kg/h capacity and AI-adjustable parameters have cut labor costs by nearly 50% compared to our old semi-automatic lines. The energy efficiency is real—we’re seeing 25% lower kWh/kg consumption. Remote diagnostics saved us during a calibration alert last month. A solid investment for any high-volume producer."Purchase Date: January 2025 | Usage Period: 7 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Richard Lin - Senior Food Engineer, Institute of Food Technologists

"This extruder sets a new benchmark in starch processing automation. The combination of ±2°C precision control, FDA-compliant materials, and scalable throughput makes it ideal for both emerging brands and multinational manufacturers. I especially commend the energy-efficient motor design—it aligns with current sustainability goals in industrial food production."

Chef Daniel Kim - Independent Food Innovation Advisor

"Having consulted for over 30 snack startups, I now recommend this machine across the board. Whether you're prototyping a new puff or scaling a traditional cassava chip, the customizable die heads and real-time parameter control allow for unmatched formulation flexibility. It’s rare to find a single machine that serves both R&D and full-scale production so effectively."

Posted: 2 days ago

"We struggled with inconsistent puff density until we optimized the pressure settings on this extruder. Now every batch is uniform. The supplier’s team helped us fine-tune the recipe—outstanding support."

Posted: 1 week ago

"Upgraded from a manual press to the Advanced Model. The automation has doubled our daily output. Cleaning is easy thanks to the disassemblable die head. Highly recommend for serious producers."

Posted: 3 weeks ago

"Excellent machine for starch research. Only downside is the weight—moving it requires two people. Otherwise, the temperature monitoring and data logging are top-notch."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.