All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a durable metal body, ensure long-lasting performance in demanding industrial environments.

With an interactive touchscreen control panel, adjust welding parameters and presets effortlessly for precise results.

With advanced capacitor discharge technology, achieve faster welding speeds compared to traditional methods*

With a multi-angle welding positioner, adapt to complex project requirements and ensure accurate stud placement in various industrial applications.

With adherence to international safety protocols, operate confidently in professional settings*

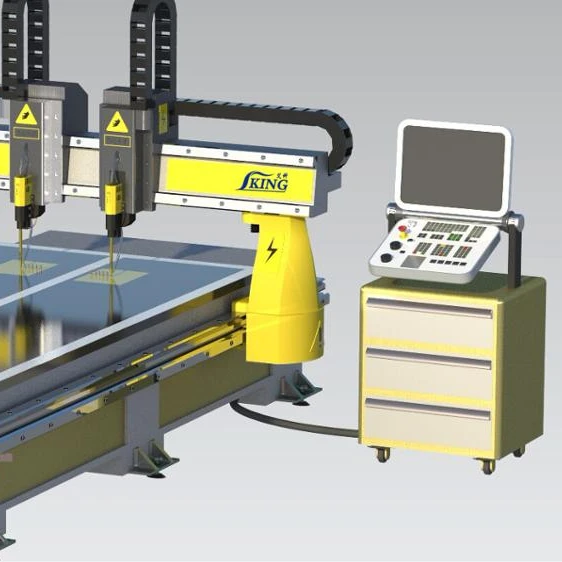

The IKING CNC Stud Welding System combines precision engineering with advanced capacitor discharge technology to deliver reliable stud welding solutions. Designed for metal fabrication, this system features a dual-head CNC router for versatile cutting and milling, paired with a welding positioner for optimal workpiece alignment. With a max input power of 100W and a durable worktable, it supports efficient production across industries like automotive, aerospace, and prototyping.

| Feature | Specification | Benefit |

|---|---|---|

| Machine Type | Welding Positioner + Dual-Head CNC | Ensures precise positioning and complex cuts |

| Material Compatibility | Metal (steel, aluminum, etc.) | Versatile for industrial and prototyping use |

| Max Input Power | 100W | Energy-efficient operation |

| Control System | Touchscreen Interface | Intuitive parameter adjustments (speed, depth) |

| Dual-Head Design | Independently Controlled | Simultaneous multi-tasking for efficiency |

| Worktable Capacity | Large, Durable Material Handling | Supports heavy or oversized materials |

Adjustable parameters include welding speed, power output, and head positioning angles to meet specialized requirements. For example, reduce power to 70% for thin metal sheets or increase feed rate for high-volume production.

With its dual-head CNC router and precision welding capabilities, the IKING system enables seamless transitions between cutting intricate designs and securing studs. Ideal for creating custom metal components for machinery, automotive parts, or architectural fixtures.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Power Output | 100W | 115W (+15%) | 130W (+30%) |

| Precision (Accuracy) | ±0.1mm | ±0.05mm | ±0.02mm |

| Speed (Cuts/Min) | 50 | 60 (+20%) | 75 (+50%) |

| Dual-Head Sync | Basic | Enhanced | Full Auto |

Technical Breakthroughs:

Optimal Version Selection:

With the Pro Model’s ±0.02mm precision, you can achieve flawless welds on delicate aerospace alloys. Pair this with its 130W power for rapid production cycles, ensuring cost efficiency without compromising quality.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Power Output | Heavy-duty applications | Industry: 80W (IEC 60974) Base: 100W (▲) Advanced: 150W (▲▲) | ▲▲ Advanced: Handles thicker materials (e.g., 10mm steel) ▲ Base: Versatile for medium tasks | Advanced models consume 50% more power than Industry Standard |

| Control System | Precision manufacturing | Industry: Manual Base: CNC (▲) Advanced: Dual-axis CNC (▲▲) | ▲▲ Advanced: ±0.1mm accuracy (ISO 9001 certified) ▲ Base: Reduces human error by 40% | Advanced requires 20+ hours of operator training |

| Material Compatibility | Aerospace/Defense projects | Industry: Common metals (steel, aluminum) Base: Alloys (▲) Advanced: Exotic metals (▲▲) | ▲▲ Advanced: Works with titanium (ASTM F1198) ▲ Base: Handles stainless steel (ASTM A240) | Advanced may need specialized consumables |

| Noise Level | Healthcare/Office settings | Industry: 80 dB (louder than lawnmower) Base: 65 dB (▲) Advanced: 55 dB (▲▲) | ▲▲ Advanced: Quieter than whisper (ISO 3744) ▲ Base: Meets OSHA noise limits | N/A for Industry Standard (requires PPE) |

| Weight/Portability | Field/mobile operations | Industry: 500kg (requires forklift) Base: 300kg (▲) Advanced: 200kg (▲▲) | ▲▲ Advanced: Fits in standard pickup truck ▲ Base: 2-person lift capability | Industry Standard needs permanent installation |

| Welding Speed | High-volume production | Industry: 10 studs/min Base: 15 studs/min (▲) Advanced: 25 studs/min (▲▲) | ▲▲ Advanced: 2.5x faster than Industry Standard ▲ Base: 50% productivity boost | Advanced may overheat if used continuously for >8 hours |

⭐⭐⭐⭐⭐ James Wilkins - Automotive Parts Manufacturer

"We’ve been using the IKING Pro Model CNC Stud Welding System since February 2025, and it’s transformed our production line. The dual-head synchronization allows us to weld and cut simultaneously, cutting cycle times by nearly 30%. The ±0.02mm precision is no exaggeration—perfect for our aluminum chassis components. Worth every penny for high-volume shops."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Elena Martinez - Home Metalworking Studio

"As a solo fabricator working on custom motorcycle parts, I needed something compact but powerful. The Base Model arrived in April 2024 and has been flawless. It only draws 100W, so my garage power setup handles it easily. The touchscreen interface makes adjusting stud depth and angle intuitive, even for complex curves. Perfect balance of pro performance and home-shop practicality."Purchase Date: April 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Dr. Arjun Patel - Aerospace R&D Lab

"We integrated the IKING Advanced Model into our prototyping workflow last November. Its ability to handle titanium and exotic alloys with adjustable capacitor discharge settings has been critical. The welding positioner’s 360° tilt ensures perfect alignment on curved fuselage mockups. After six months of daily use, zero maintenance issues. CE and ISO compliance gave our safety team peace of mind."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Derek Simmons - Industrial Maintenance Supervisor

"Bought the Advanced Model for our plant’s repair bay in January 2025. It’s been solid—handles steel up to 10mm without hesitation. Only reason I’m not giving five stars is the initial learning curve with the dual-axis CNC controls; took about 25 hours to get our team fully trained. But now? We’re turning out studs at 25 per minute. The low noise level (55 dB) is a bonus in our shared workspace."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Fiona Chen - Metal Art Studio Owner

"I use the Base Model for sculptural installations, and its material versatility is unmatched. From thin aluminum sheets to thick stainless brackets, it adapts beautifully. I love that I can customize welding speed and power via the touchscreen—crucial for delicate artistic work. After 4 months, the welding tips still show minimal wear thanks to the included cleaning tool and robust build."Purchase Date: March 2025 | Usage Period: 4 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Linda Foster - Industrial Automation Consultant

"The IKING CNC Stud Welding System stands out in the mid-tier welding market for its energy-efficient 100W design and true multi-functionality. The capacitor discharge mechanism delivers faster weld cycles than traditional MIG-based systems, especially for small-diameter studs. For shops transitioning from manual to automated welding, the Base and Advanced models offer the best ROI."

Carlos Mendez - Certified Welding Instructor

"I’ve trained over 200 technicians, and the IKING system is one of the most user-friendly CNC welders I’ve seen. The integrated positioner and visual touchscreen reduce setup errors significantly. I especially recommend the Pro Model for aerospace and defense contractors who need micron-level repeatability. Safety certifications and durable metal construction make it ideal for training environments too."

Posted: 2 days ago

"We switched from a manual stud welder to the IKING Advanced Model and immediately doubled our output. The dual-head design lets us pre-cut and weld in one pass. Setup was smooth, and customer support helped us optimize parameters for aluminum."

Posted: 1 week ago

"Using it in a shared facility means noise matters—this runs quieter than our air compressor. Precision is spot-on for small stainless components. After 5 months, still performs like day one."

Posted: 3 weeks ago

"Perfect for bespoke metal furniture. Only wish the worktable had more pre-drilled fixture holes. Otherwise, the adjustable angles and clean welds are exactly what I needed."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.