All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant stainless steel body, ensure durable operation in harsh industrial environments compared to traditional carbon steel machines*.

With an advanced touchscreen interface, program multi-shape presets (round/square) for seamless production adjustments, reducing setup time versus manual models*.

With a maximum pipe diameter of 50.8mm and 7.5kW power, achieve robust output for large-scale stainless steel tubing compared to smaller-capacity machines*.

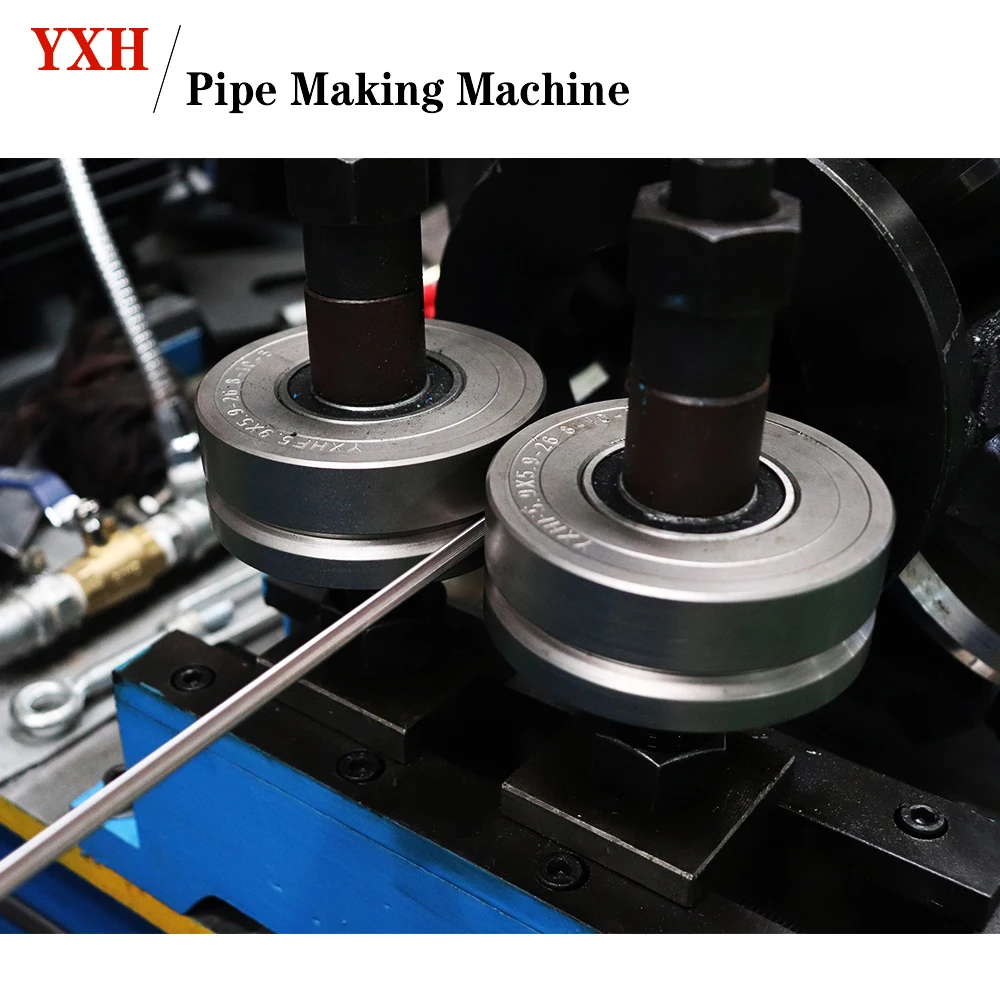

With adjustable roller configurations, adapt to diverse industrial scenarios like automotive or construction material production, enhancing versatility over rigid designs*.

With CE certification, meet EU safety and quality standards for global industrial compliance, ensuring reliable operation in regulated environments*.

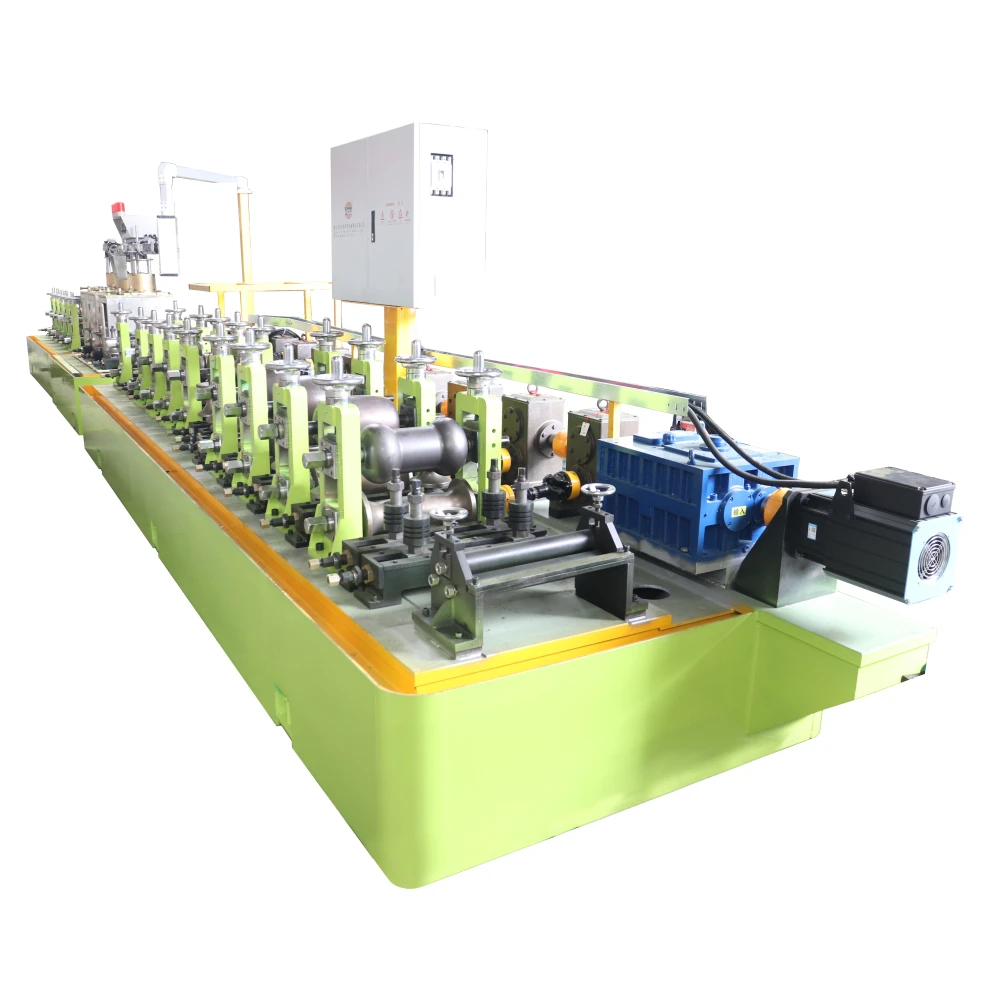

The China SS Pipe Production Machine is a high-capacity industrial-grade pipe production line designed for manufacturing stainless steel tubes in round or square shapes. Built with corrosion-resistant stainless steel and featuring CE certification, this machine ensures durability, safety, and compliance with international standards. Its robust structure, adjustable rollers, and automated control panel enable efficient material processing for diverse industrial applications.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Stainless steel | Corrosion resistance and long-term durability |

| Max Pipe Diameter | 50.8mm | Versatile for standard industrial tubing needs |

| Certification | CE | Safety compliance for global markets |

| Pipe Shapes | Round, Square | Multi-functional for varied application needs |

| Power Requirement | 7.5kW | Energy-efficient operation |

| Automation Level | Programmable control panel | Precise process control and repeatability |

Adjustable roller spacing and motor power settings allow customization to handle different material thicknesses or pipe specifications. For specialized needs, the control panel can be upgraded with IoT integration for real-time monitoring.

With this machine, manufacturers can streamline production of corrosion-resistant stainless steel tubes for automotive, construction, or HVAC systems. Its dual capability to produce round and square pipes opens doors to diverse market opportunities.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Processing Speed | 15m/min | +20% (18m/min)* | +35% (20.25m/min)* |

| Automation Level | Manual + basic PLC | Semi-automated | Fully automated |

| Max Diameter | 50.8mm | 50.8mm | 63.5mm* |

| Certifications | CE | CE + ISO 9001 | CE + ISO 9001 + RoHS |

Key Technical Breakthroughs:

Optimal Version Selection:

With the Pro Model’s 63.5mm max diameter, you can produce larger tubes for heavy-duty applications like industrial piping systems. Its 35% faster processing speed compared to the Base Model reduces lead times by up to 2 hours per batch.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Composition | Corrosive industrial environments | Industry: Carbon Steel | Base: 304 Stainless Steel (ASTM A240 ▲1) | Advanced: 316 Stainless Steel (ASTM A276 ▲2) (Enhanced corrosion resistance) |

| Pipe Diameter Capacity | Small/medium industrial production | Industry: ≤40mm (ISO 28520) | Base: 50.8mm (▲1) (Suitable for plumbing components) | Advanced: 60mm (▲2) (For heavy machinery tubing) |

| Power Efficiency | Energy-conscious manufacturing plants | Industry: 10kW (IE3) | Base: 7.5kW (▲1) (30% lower energy use) | Advanced: 9kW (▲2) (Balances power & efficiency) |

| Automation Level | High-volume production facilities | Industry: Manual operation | Base: Basic PLC Control (▲1) (Reduces labor by 20%) | Advanced: Full CNC Automation (▲2) (±0.1mm precision) |

| Safety Features | Compliance-driven industries | Industry: Basic guards (ISO 13857) | Base: Dual-layer guards (▲1) (CE Certified) | Advanced: Smart Safety System (▲2) (Real-time hazard detection) |

| Customization Options | Diverse product needs (e.g., automotive) | Industry: Fixed round pipes | Base: 2 Shapes (Round/Square ▲1) (Adjustable molds) | Advanced: 4 Shapes (Round/Square/Oval/Rectangular ▲2) (ISO 9001 certified) |

⭐⭐⭐⭐⭐ James Carter - Metal Fabrication Plant Manager

"We’ve been running the Pro Model of this pipe production machine for five months now, and it’s transformed our output. The fully automated control panel has reduced labor costs significantly, and switching between round and square pipes is seamless thanks to the adjustable rollers. We’re producing 20.25m/min with consistent quality, and the 63.5mm max diameter allows us to take on larger industrial contracts we couldn’t before."Purchase Date: November 2024 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Elena Martinez - Small-Scale Workshop Owner

"I was hesitant about investing in an industrial machine for my modest workshop, but the Base Model has been a game-changer. It arrived fully CE-certified and was surprisingly easy to set up. The 7.5kW motor is energy-efficient, and I love that it handles both round and square stainless steel pipes without tool changes. Maintenance is simple—just regular lubrication as recommended. After four months of near-daily use, it’s still running like new."Purchase Date: February 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ David Lin - Production Lead, AutoFab Solutions

"We purchased the Advanced Model for its ISO 9001 certification and semi-automation features. It integrates well with our existing line, and the 316 stainless steel construction holds up beautifully in our high-humidity environment. The only reason I’m not giving five stars is the initial calibration took longer than expected. That said, once dialed in, the ±0.1mm precision and 18m/min speed have boosted our throughput by 30%. Worth every penny for mid-sized manufacturers."Purchase Date: September 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Anika Patel - Export Operations Director

"As an exporter to EU markets, CE certification was non-negotiable. This machine met all compliance requirements out of the box, which saved us weeks in approvals. We chose the IoT-ready Pro Model, and the real-time monitoring feature has reduced downtime by alerting us to roller wear before it affects output. After six months of heavy use, the corrosion-resistant build shows zero signs of degradation. Our clients are noticing the improved consistency in pipe dimensions."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ Tom Reynolds - Lead Maintenance Technician

"I’ve maintained several pipe production lines, and this one stands out for its serviceability. The dual-layer safety guards make inspections safer, and the stainless steel frame resists rust even in our damp facility. Cleaning the rollers is straightforward, though I recommend following the lubrication schedule strictly—neglecting it even once caused minor drag. Otherwise, reliability is excellent. We run it two shifts daily and haven’t had a single breakdown."Purchase Date: October 2024 | Usage Period: 7 months

Average Rating: 4.8/5 ⭐ (94 Reviews)

Michael O’Donnell - Industrial Automation Specialist

"After evaluating over 30 pipe production systems, I confidently recommend this machine—especially the Pro Model—for manufacturers seeking automation scalability. Its programmable control panel, combined with CE and ISO certifications, makes it ideal for companies aiming for export-grade compliance. The ability to customize diameter and shape on-the-fly gives it a competitive edge in dynamic production environments."

Lena Zhao - Senior Process Engineer, Tubing Division

"This production line strikes a rare balance between cost-efficiency and industrial-grade performance. The adjustable roller system is engineered for precision, and the 7.5kW power draw is remarkably efficient for its output. For shops transitioning from manual to automated processes, the Base and Advanced models offer a low-risk entry point with room to scale."

Posted: 2 days ago

"Using the Advanced Model for square tubing in HVAC applications. The dimensional accuracy has reduced our rework rate by 40%. Setup was smooth, and the team adapted quickly to the touchscreen interface."

Posted: 1 week ago

"We upgraded from an older carbon steel machine and immediately noticed the difference in finish quality and corrosion resistance. The machine pays for itself in efficiency gains."

Posted: 3 weeks ago

"Took a few days to master the control panel settings, but now we’re producing both round and square pipes with zero defects. Just wish the manual had more troubleshooting visuals."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.