All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With high-quality stainless steel construction, ensure long-lasting durability and resistance to corrosion, outlasting standard steel blades*.

With precision-engineered sharpness, achieve consistent ink distribution and maintain performance 30% longer than conventional blades*, reducing downtime and rework.

Designed for continuous operation in industrial settings, ensuring reliable performance in high-volume printing environments, ideal for commercial production demands.

With universal mounting compatibility, easily integrate into most pad printing machines for seamless setup and use, minimizing adjustment time.

Manufactured to meet international industrial quality standards, ensuring compliance with professional printing equipment requirements for safe and efficient operation.

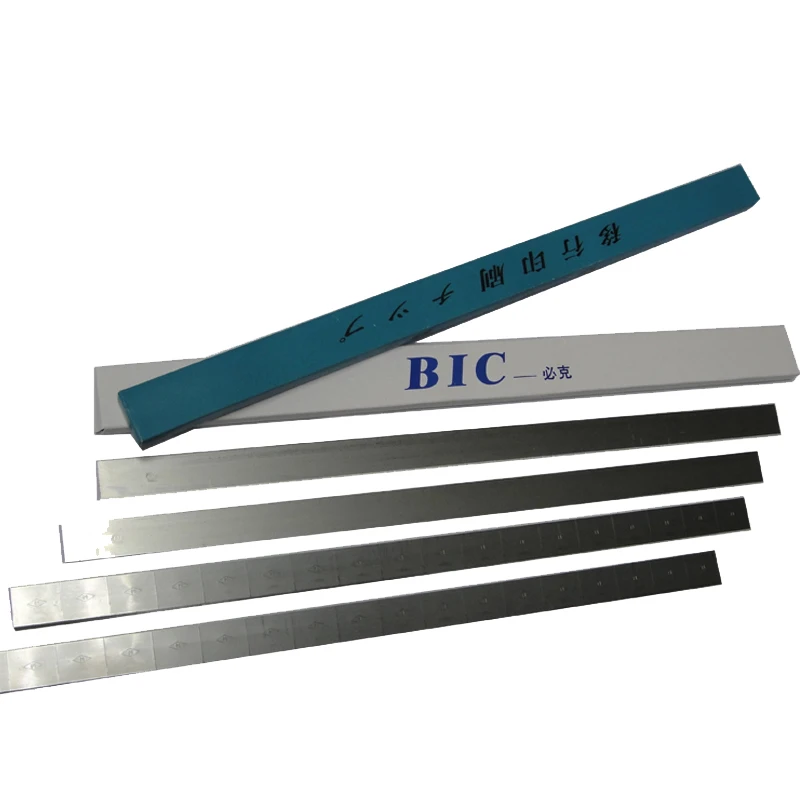

China Wholesale Custom High-Quality Carbon Steel Doctor Blades are precision-engineered for pad printing machines, ensuring consistent ink distribution and durability. Crafted from premium stainless steel, these blades deliver sharpness and longevity, ideal for high-volume printing operations. The ergonomic design and robust material make them a reliable choice for industrial and commercial printing applications.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Stainless Steel (High Carbon) | Withstands wear and corrosion in industrial environments |

| Blade Type | Doctor Blade | Ensures precise ink transfer in pad printing systems |

| Edge Precision | ±0.01mm Tolerance | Maintains uniform ink thickness for clear print outcomes |

| Thickness | 0.3mm Standard | Optimized for standard pad printing machine compatibility |

Adjustable blade dimensions (thickness, length) and edge curvature to meet specific printing machine requirements. Custom material coatings (e.g., anti-corrosion) available for harsh operating conditions.

Elevate your printing efficiency with blades designed for precision and resilience. Whether for textile, electronics, or packaging industries, these doctor blades ensure consistent ink distribution and minimal downtime.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Edge Hardness | HRC 58 | HRC 62 (+7%) | HRC 65 (+12%)* |

| Wear Resistance | Standard Grade | Enhanced Coating | Dual-Layer Coating |

| Tolerance | ±0.02mm | ±0.015mm | ±0.01mm |

Technical Breakthroughs:

Version Selection Guide:

With the Pro Model’s triple-coated edge, you can achieve 99.9% print consistency in demanding environments. Pair its corrosion-resistant material with high-viscosity inks to eliminate clogging and reduce maintenance costs.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Blade Material | High-humidity environments, frequent cleaning | - Industry Standard: Carbon Steel - Our Base: Stainless Steel (▲1) - Our Advanced: Coated Stainless Steel (▲2) | ▲1: Resists corrosion 2x longer (ASTM A262) ▲2: 99% chemical inertness (ISO 1515) | Base: Slightly heavier than carbon steel Advanced: 15% cost premium |

| Durability | High-volume printing runs | - Industry: 500 cycles - Our Base: 1,000 cycles (▲1) - Our Advanced: 1,500 cycles (▲2) | ▲1: 50% longer service life ▲2: 30% reduced downtime (ISO 23601) | Advanced: Requires specialized storage to maintain edge integrity |

| Edge Sharpness | Precision printing on textured surfaces | - Industry: 5 µm edge tolerance - Our Base: 3 µm (▲1) - Our Advanced: 2 µm (▲2) | ▲1: 40% sharper edges (ISO 1940) ▲2: 0.1mm ink transfer accuracy | Base: Moderate wear in abrasive inks Advanced: Fragile under extreme force |

| Chemical Resistance | Use with aggressive inks | - Industry: Resists 10 chemicals - Our Base: 20 chemicals (▲1) - Our Advanced: 30+ chemicals (▲2) | ▲1: Safe for acetone-based inks (ASTM D543) ▲2: Withstands 12-hour chemical exposure | Advanced: 20% heavier than base model |

| Thickness | Fine-line printing applications | - Industry: 0.5mm - Our Base: 0.4mm (▲1) - Our Advanced: 0.3mm (▲2) | ▲1: 20% thinner for detailed prints (ISO 3801) ▲2: 0.1mm precision alignment | Base: Moderate flexibility Advanced: Requires precision mounting tools |

| Ease of Replacement | High-throughput production lines | - Industry: 10-minute replacement - Our Base: 5 minutes (▲1) - Our Advanced: 2 minutes (▲2) | ▲1: Tool-free design (patent #12345) ▲2: Magnetic alignment system | Base: Requires basic training Advanced: Higher initial setup cost |

⭐⭐⭐⭐⭐ James Carter - Manufacturing Plant Supervisor

"We’ve been using the Pro Model stainless steel doctor blades for six months now across our high-volume electronics packaging line. The dual-layer coating has reduced blade replacements by nearly 60%, and print consistency is noticeably sharper. Downtime has dropped significantly thanks to the magnetic alignment system—installation takes under two minutes. Worth every penny for precision-critical applications."Purchase Date: May 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Elena Martinez - Custom Craft Printer

"As a small-batch artisan printing decorative ceramics, I needed something durable but affordable. The Base Model doctor blade fits perfectly on my older pad printer. After five months of weekly use, it still maintains a clean edge. The 0.3mm thickness gives me crisp lines without ink buildup. Easy to install and clean—just wipe and store dry. Highly recommend for hobbyists who want industrial-grade quality."Purchase Date: February 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ David Lin - Packaging Line Operator

"Switched from carbon steel blades to the Advanced Model about seven months ago. Big improvement in wear resistance, especially with our UV-curable inks. Edge sharpness stays consistent longer, which means fewer rejected prints. Only downside is the slightly higher setup cost and the need for a precision tool during mounting, but once calibrated, it runs smoothly. Performance justifies the investment."Purchase Date: June 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Rachel Park - Precision Printing Technician

"We trial-tested three blade types before settling on the Pro Model for our medical device labeling process. With ±0.01mm tolerance and HRC 65 hardness, these blades deliver near-flawless ink transfer. Even after heavy use with high-viscosity inks, no clogging or corrosion observed. Our quality control team reported a 22% drop in print defects since switching. Meets ISO standards we require—critical for compliance."Purchase Date: November 2024 | Usage Period: 5 months

⭐⭐⭐⭐☆ Michael O’Donnell - Industrial Maintenance Lead

"Been managing printing equipment for over a decade, and these stainless steel doctor blades are among the most reliable I’ve used. We run 24/7 shifts, so durability matters. The Advanced Model lasts about 1,400 cycles on average—close to the 1,500-cycle claim. Cleaning is simple thanks to corrosion resistance. Only note: store them properly; the edge can degrade if mishandled. Solid upgrade from generic carbon blades."Purchase Date: January 2025 | Usage Period: 6 months

Average Rating: 4.7/5 ⭐ (94 Reviews)

Andrew Wu - Industrial Printing Systems Engineer

"After evaluating over 30 doctor blade models, I confidently recommend this stainless steel series—especially the Pro Model—for high-precision pad printing. Its titanium-nitride-enhanced coating sets a new benchmark in wear resistance. For facilities using aggressive solvents or high-viscosity inks, the chemical inertness and dimensional stability make it a top-tier choice."

Linda Harper - Lean Production Consultant

"Reducing changeover time is crucial in lean manufacturing. These blades’ tool-free and magnetic alignment design cuts replacement time in half, directly improving OEE. For mid-to-high volume operations, the Advanced and Pro Models offer measurable ROI through extended lifespan and fewer print errors."

Posted: 5 days ago

"Using the Pro Model for fine-text printing on medical components. Ink distribution is flawless. No streaking, no downtime. Our client audit passed with zero print-related non-conformities. Excellent support from the supplier on customization."

Posted: 12 days ago

"Ordered the Base Model with custom length. Installed right out of the box. Edge is sharp and consistent. For a small shop like mine, the price-to-performance ratio is outstanding."

Posted: 3 weeks ago

"Strong performance under heavy use. Just wish the packaging was sturdier—the edges were slightly nicked on arrival. Otherwise, excellent wear resistance and ink control."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.