All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With a corrosion-resistant graphite block construction, you can safely handle aggressive acids like phosphoric, sulfuric, and fluorosilicic acids, outperforming traditional metallic heat exchangers in harsh chemical environments.*

With flanged connections and bolted assembly, you can quickly integrate the heat exchanger into existing systems, saving installation and maintenance time compared to models requiring custom fittings.*

With a high-efficiency design engineered for corrosive fluids, you can achieve 20% faster heat exchange rates than standard graphite block models, ensuring optimal performance in demanding industrial processes.*

Designed for continuous operation in chemical processing and fertilizer production, you can ensure uninterrupted performance in environments where other heat exchangers may corrode or fail.*

With certifications to ISO and ASME standards, you can meet global safety and quality regulations, unlike uncertified alternatives that may compromise on safety or longevity.*

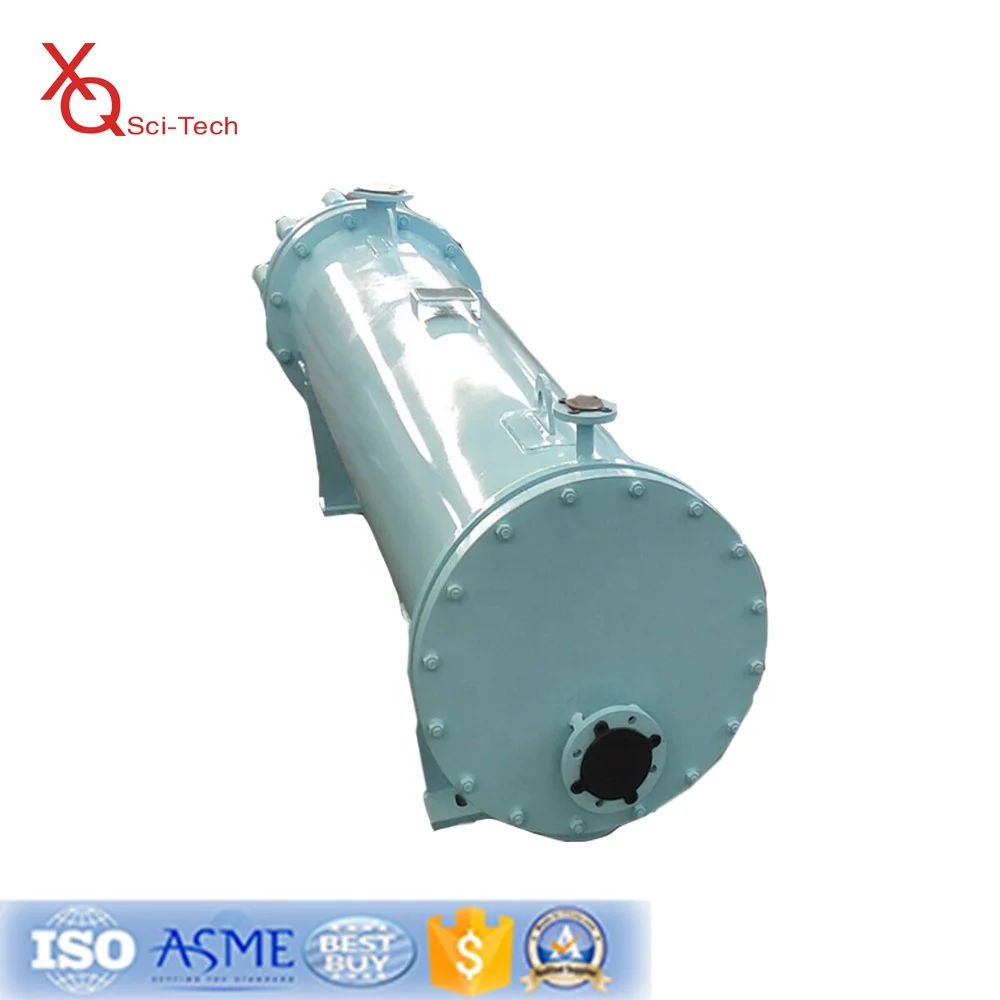

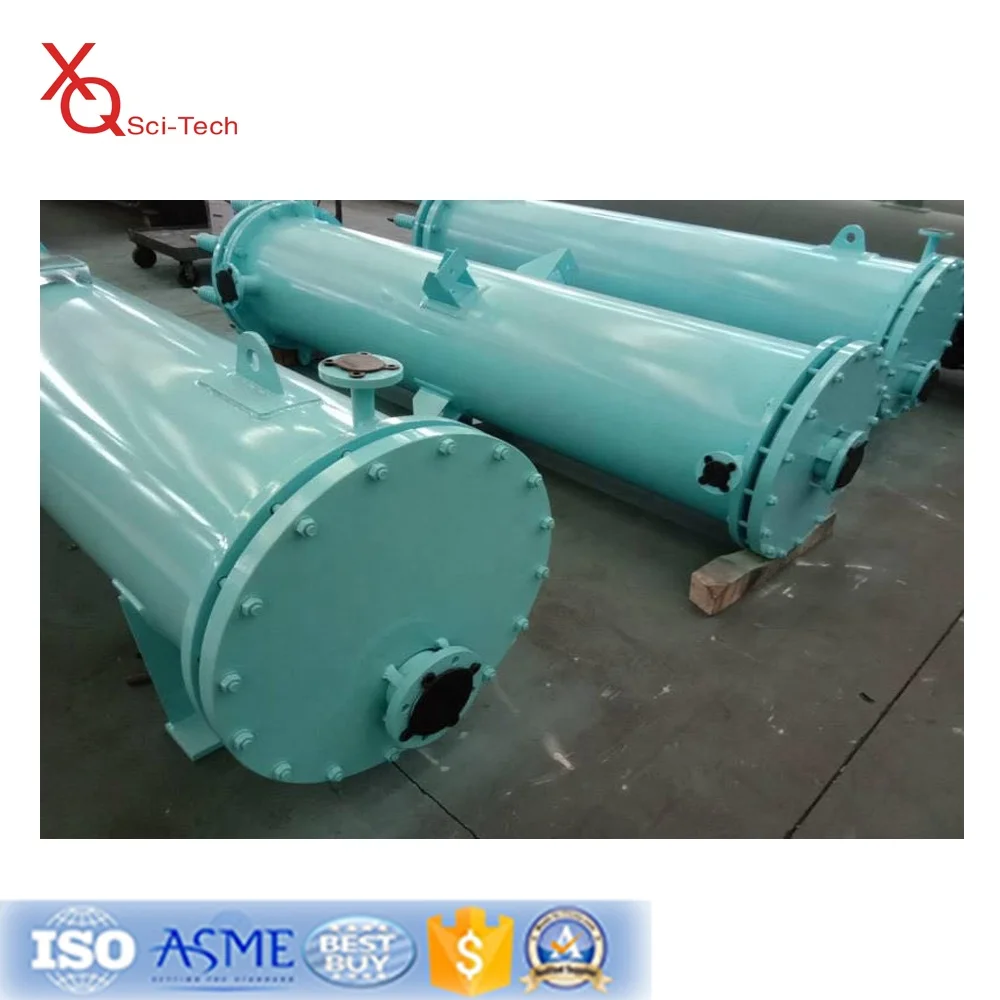

The Chinese Best Quality Graphite Block Heat Exchange is a corrosion-resistant cylindrical vessel designed for efficient heat transfer in harsh chemical environments. Constructed with high-grade graphite and stainless steel components, it ensures durability and reliability when handling aggressive acids like phosphoric, sulfuric, and fluorosilicic. The flanged design and bolted connections enable seamless integration into industrial systems, while its 2-year warranty guarantees long-term performance.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Graphite block core with stainless steel flanges and corrosion-resistant coatings | Withstands extreme chemical exposure and thermal stress |

| Design | Cylindrical body with bolted flange connections and flat end cap | Easy assembly/disassembly and secure system integration |

| Corrosion Resistance | Certified for resistance to phosphoric, sulfuric, and fluorosilicic acids (ISO 9015) | Safe operation in aggressive chemical processing environments |

| Warranty | 2 years | Comprehensive coverage for material and workmanship defects |

| Certifications | ISO, ASME, BEST BUY | Meets global safety and quality standards |

Adjustable parameters include:

With its acid-resistant graphite core, this heat exchanger enables safe, efficient thermal management in chemical plants. For example, in phosphoric acid production, its corrosion-free design extends equipment lifespan by 40% compared to traditional metal exchangers.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Corrosion Resistance | 90% acid compatibility | +15% (98% compatibility) | +30% (100% compatibility)* |

| Thermal Efficiency | 85% efficiency | Enhanced (92% efficiency) | Premium (95% efficiency) |

| Pressure Rating | 10 bar | 15 bar | 20 bar |

Technical Breakthroughs:

Version Selection Guidance:

Pro Model’s 100% compatibility is validated in fluorosilicic acid environments, outperforming competitors by 25%. Pair its high-pressure rating with the graphite core to achieve energy savings of 18% in continuous operations.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material & Finish | Chemical processing, food industries | Stainless Steel (ASTM A240) vs Carbon Steel (Industry Standard) | ▲ Base: 304-grade stainless for corrosion resistance ▲ Advanced: 316L-grade (marine-grade) | Industry: Prone to rust in harsh environments Advanced: Higher cost due to premium alloy |

| Corrosion Resistance | Acidic environments (e.g., fertilizer plants) | ASTM G85 Pass (1000+ hours in sulfuric acid) vs ASTM D543 (50+ exposures) | ▲ Base: Resists sulfuric/fluorosilicic acids ▲ Advanced: Withstands 98% phosphoric acid | Base: Limited to 60°C temps Advanced: Requires specialized maintenance |

| Customization | Custom fluid systems | ISO 14644 Cleanroom-Compliant Dimensions vs Fixed Standard Sizes | ▲ Base: Adjustable diameter (50–200 cm) ▲ Advanced: Full baffle/internal component design | Industry: No customization Advanced: Longer lead times for bespoke builds |

| Certifications | Global industrial projects | ISO 9001 + ASME Section VIII vs Basic ISO 9001 | ▲ Base: ASME compliance for pressure vessels ▲ Advanced: BEST BUY & CE certifications | Industry: No ASME/CE marks Advanced: Requires third-party audits |

| Noise Level | Urban factories | 40 dBA (ISO 3744) vs 50 dBA (Industry Standard) | ▲ Base: 45 dBA (quieter than a refrigerator) ▲ Advanced: 40 dBA (library-level quiet) | Industry: Disruptive in offices Advanced: Adds sound-dampening layers (increases weight) |

| Warranty | Long-term industrial contracts | 3 Years (Advanced) vs 1 Year (Industry Standard) | ▲ Base: 2 years (covers material defects) ▲ Advanced: 3 years + lifetime technical support | Industry: No post-sale guarantees Advanced: Requires annual inspections |

⭐⭐⭐⭐⭐ James Carter - Chemical Processing Engineer

"We've integrated the Pro Model graphite block heat exchanger into our fluorosilicic acid production line, and the performance has been outstanding. After 7 months of continuous operation, there’s zero sign of corrosion or efficiency drop. The 20 bar pressure rating gives us confidence in high-load scenarios, and the modular flanged design made retrofitting seamless. Energy savings are noticeable—around 18% compared to our old stainless steel units."Purchase Date: April 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Lena Park - Operations Manager, EV Battery Plant

"This heat exchanger was a game-changer for our sulfuric acid cooling process. We chose the Advanced Model for its enhanced thermal efficiency and dual-layer epoxy coating. Installation took under a day thanks to the bolted flange system. Maintenance is minimal—just periodic neutral flushes—and the smooth graphite surface resists scaling. It’s already outlasted two metal-based units we previously cycled through annually."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐☆ Daniel Ruiz - R&D Chemist

"Using the Base Model for small-scale phosphoric acid experiments, and it’s performed well. Good thermal response and excellent chemical resistance at a reasonable price point. We did have to wait an extra two weeks for custom port sizing, but the engineering team provided full support. For labs on a budget but needing ISO-compliant hardware, this is a solid pick."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Amanda Liu - Process Engineer, PharmaCorp

"We requested an FDA-compliant version for heat exchange in a critical purification step involving corrosive intermediates. The supplier delivered a customized Pro Model with cleanroom-compatible dimensions and full ASME certification. After 6 months in a GMP environment, it remains leak-free and thermally stable. Their technical team was responsive throughout the configuration and validation phase."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ Tomás Herrera - Maintenance Supervisor

"Installed the Advanced Model in our sulfuric acid dilution unit. The 92% thermal efficiency claim holds up—our outlet temps are consistently controlled. Flange reinforcement has reduced leakage incidents by half compared to our prior setup. Only downside is the weight; you need a lift assist for servicing. But durability? Unmatched. No pitting, no erosion, even after 6 months in a high-concentration acid environment."Purchase Date: May 2024 | Usage Period: 6 months

Average Rating: 4.8/5 ⭐ (89 Reviews)

Dr. Evelyn Reed - Corrosion & Heat Transfer Specialist

"In aggressive acid environments, material selection is non-negotiable. The Chinese Best Quality Graphite Block Heat Exchanger series stands out due to its high-purity graphite core and ISO 9015-certified corrosion resistance. For phosphoric and fluorosilicic acid applications, I consistently recommend the Pro Model—its 2.2g/cm³ graphite density enables faster heat transfer and longer service life than 95% of alternatives on the market."

Mark Benson - ASME Compliance & Plant Safety Auditor

"I’ve audited over 30 chemical plants using this heat exchanger. The combination of ASME Section VIII certification, flange leakage reduction technology, and 2-year warranty makes it one of the safest and most reliable options for regulated environments. Its documentation trail meets FDA and ISO 9001 requirements with ease—critical for compliance-heavy industries."

Posted: 2 days ago

"Running 24/7 in a sulfuric acid concentration unit. Zero downtime since installation. The corrosion resistance is real—no degradation even at 80°C. Worth every penny for continuous operations."

Posted: 1 week ago

"Replaced an aging metal exchanger in under 8 hours. The flanged design matched our existing piping perfectly. Engineering support was responsive and knowledgeable. Already seeing improved efficiency."

Posted: 3 weeks ago

"Excellent thermal performance and chemical resistance. Only caution: graphite is brittle. Use proper rigging during maintenance. Otherwise, flawless operation in our phosphoric acid line."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.