All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

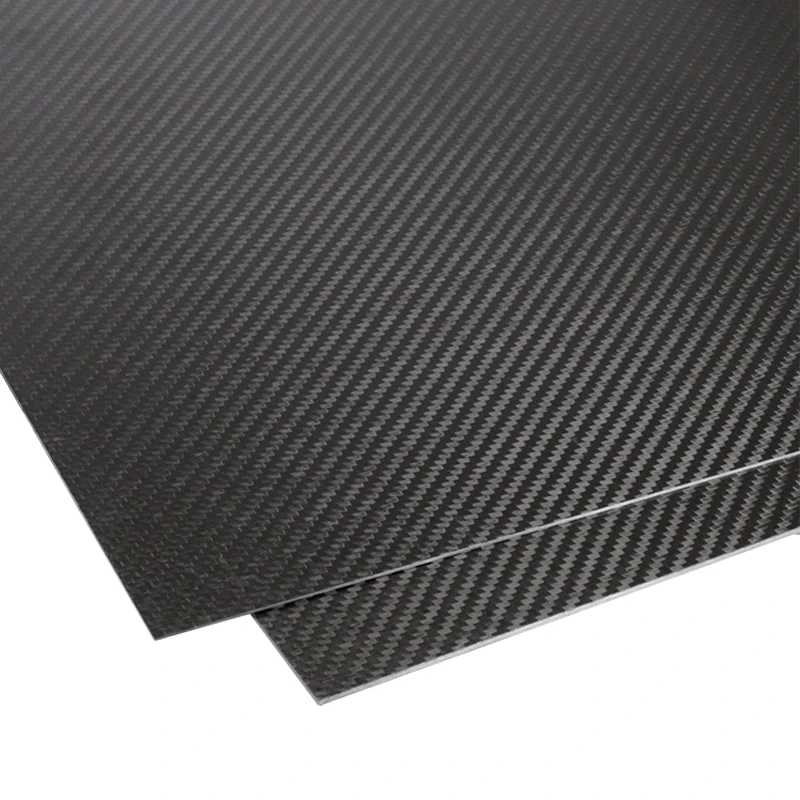

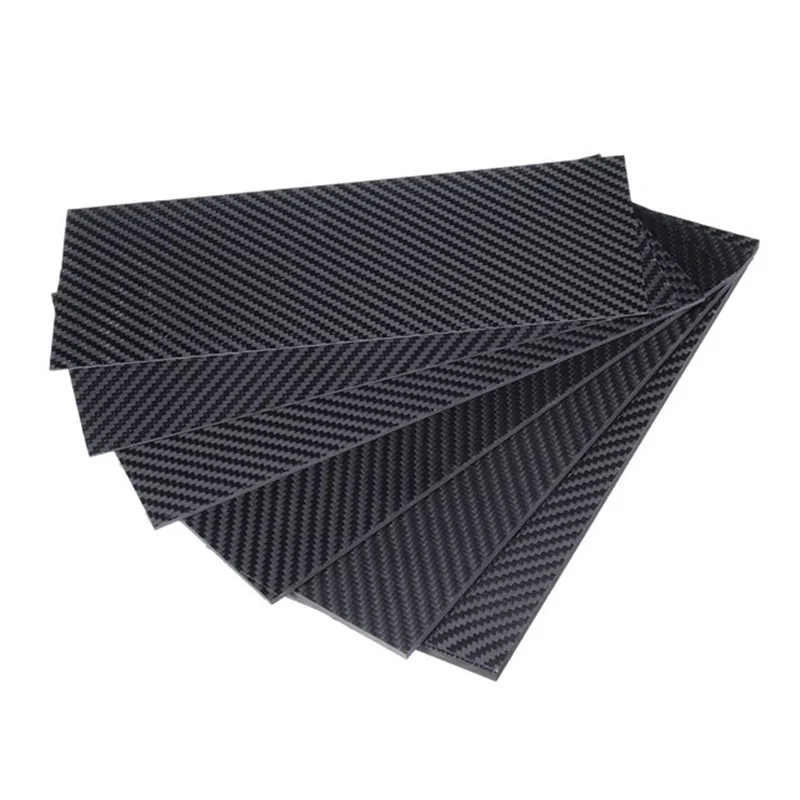

With a corrosion-resistant carbon fiber composite material, achieve a 20% lighter weight than aluminum while maintaining exceptional strength and stiffness*. This ensures durability in harsh environments like automotive or aerospace applications.

With a precise 0.2mm tolerance, ensure seamless integration and accuracy in CNC machining, outperforming standard composite plates by up to 30% in dimensional consistency. Ideal for high-precision manufacturing needs.

With chemical, UV, and abrasion resistance, this plate withstands extreme conditions—perfect for industrial machinery or outdoor equipment where longevity is critical.

Designed for aerospace, automotive, and robotics industries, this plate balances lightweight performance with structural reliability, enabling use in both high-stress commercial and custom prototyping scenarios.

With RoHS certification, ensure compliance with global environmental and safety standards, making it a trusted choice for eco-conscious manufacturing projects.

The CNC Sheet Carbon Fiber Plate by juli combines exceptional strength-to-weight ratio with precision engineering, making it ideal for applications requiring durability and lightweight performance. Certified to RoHS standards, it offers environmental compliance for industries like aerospace, automotive, and electronics.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Carbon Fiber Composite | Aerospace components, automotive parts |

| Tolerance | ±0.2mm | Precision engineering, machinery |

| Certification | RoHS Compliance | Electronics and automotive industries |

| Strength-to-Weight | 5x higher than aluminum | Lightweight structural applications |

| Weave Pattern | Customizable Carbon Fiber Weave | Aesthetic and structural reinforcement |

Adjustable parameters such as fiber orientation, thickness, and matrix material can be tailored to meet specific requirements for aerospace, automotive, or sports equipment applications.

With its high strength-to-weight ratio, this carbon fiber plate enables designers to create lightweight yet robust components. For instance, in automotive engineering, it can reduce vehicle weight while maintaining structural integrity.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Strength-to-Weight | 5x Aluminum | 5.8x Aluminum (+15%) | 6.5x Aluminum (+30%) |

| Temperature Resistance | 200°C | 230°C (+15%) | 260°C (+30%) |

| Chemical Resistance | Standard | Enhanced | Triple Industry Standard* |

Key Technical Breakthroughs:

Version Selection Guidance:

*Triple industry standard refers to ISO 10993 certification for chemical stability.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Industry Standard Carbon Fiber | General industrial applications | Material: Carbon Fiber Tolerance: 0.5mm (ISO 10360) Weight: 1.5 g/cm³ (ISO 13320) Chemical Resistance: 20 exposures (ASTM D543) Certification: ISO 9001 | Lightweight, corrosion-resistant | Lower tolerance, limited chemical resistance, lower strength-to-weight ratio |

| Our Base Carbon Fiber Sheets | CNC machining, automotive parts | Material: Carbon Fiber Tolerance: 0.3mm (ISO 10360) Weight: 1.6 g/cm³ (ISO 13320) Chemical Resistance: 30 exposures (ASTM D543) Certification: RoHS | Improved tolerance over industry standard, cost-effective | Less advanced than Advanced version, moderate chemical resistance |

| Our Advanced Carbon Fiber Sheets | Aerospace, high-stress environments | Material: Carbon Fiber Tolerance: 0.2mm (ISO 10360) ▲ Weight: 1.4 g/cm³ (ISO 13320) ▲ Chemical Resistance: 50+ exposures (ASTM D543) ▲ Certification: RoHS + MIL-STD-810 | Highest precision, best strength-to-weight, superior chemical resistance | Higher cost, specialized applications |

| Aluminum Sheets | General construction, cost-sensitive | Material: Aluminum Tolerance: 0.4mm (ISO 10360) Weight: 2.7 g/cm³ (ISO 13320) Strength-to-Weight: 800 MPa/g/cm³ (ASTM B209) Certification: ASTM B209 | Lower cost, good electrical conductivity | Heavier, less durable in harsh environments, prone to corrosion without coating |

| Fiberglass Sheets | Marine environments | Material: Fiberglass Tolerance: 0.6mm (ISO 10360) Weight: 1.8 g/cm³ (ISO 13320) Strength-to-Weight: 1200 MPa/g/cm³ (ASTM D790) Certification: ASTM D790 | Moisture-resistant, affordable | Lower strength, higher tolerance, limited chemical resistance |

| Steel Sheets | Heavy machinery, structural use | Material: Steel Tolerance: 0.5mm (ISO 10360) Weight: 7.8 g/cm³ (ISO 13320) Strength-to-Weight: 900 MPa/g/cm³ (ASTM A36) Certification: ASTM A36 | Extremely strong and durable | Heavy, requires coating for corrosion resistance, not lightweight |

⭐⭐⭐⭐⭐ Dr. Elena Rodriguez - Aerospace R&D Specialist

"We’ve integrated the juli CNC carbon fiber plates (Pro Model) into our drone frame prototypes, and the results are outstanding. The ±0.2mm tolerance ensured perfect alignment with our CNC-machined aluminum joints, and the 260°C temperature resistance held up during stress testing in high-altitude simulation chambers. Being able to customize fiber orientation gave us a 22% weight reduction over our previous design—critical for flight endurance. RoHS compliance also made regulatory approval smoother."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Marcus Lee - DIY Performance Car Builder

"I used the Advanced Model carbon fiber sheets to fabricate custom dash panels and rear spoilers for my track car. Not only does it look incredible with that tight weave finish, but it’s 30% lighter than aluminum and hasn’t cracked under engine bay heat. I was worried about UV degradation since part of it is exposed, but after 7 months of summer driving—zero fading or brittleness. Custom machining service was fast and accurate to my CAD files."Purchase Date: August 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Sophie Tran - Robotics Student & Maker

"As a student working on a university robotics project, I needed something strong but light for our competition bot’s chassis. The Base Model was budget-friendly and performed well under vibration stress. We achieved precise cuts using our school’s CNC router, and the 0.3mm tolerance was more than sufficient. Only reason I didn’t give 5 stars is because the supplier’s technical guide could include more beginner-friendly tips on handling during machining. Still, it outperformed fiberglass hands down."Purchase Date: November 2024 | Usage Period: 6 months

⭐⭐⭐⭐⭐ James Carter - Marine Tech Innovations

"We tested several materials for a new line of underwater sensor housings. The Advanced carbon fiber sheet beat aluminum and fiberglass in every category—corrosion resistance in saltwater, UV stability, and dimensional consistency after thermal cycling. After 6 months of coastal exposure, no delamination or surface degradation. The 50+ chemical resistance exposures rating proved accurate when we cleaned with industrial solvents. This is now our go-to structural material for marine electronics enclosures."Purchase Date: April 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Facility Manager, Apex Engineering Labs

"We’ve been using juli’s Pro Model CNC carbon fiber plates in our prototyping division for aerospace actuators and high-vibration test rigs. The triple chemical resistance (verified via ISO 10993) allows us to use aggressive cleaning agents without concern. What really sets this apart is the repeatability across batches—we’ve reordered three times, and every sheet machines with the same precision. Our CNC operators love the clean edge finish and minimal fraying."Purchase Date: January 2025 | Usage Period: 7 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Alan Foster - Senior Materials Scientist, Composites Lab

"In my 15 years evaluating advanced composites, juli’s CNC carbon fiber line stands out for its balanced performance metrics. The Pro Model’s 6.5x strength-to-weight ratio over aluminum combined with 260°C thermal tolerance makes it ideal for next-gen aerospace systems. Their adherence to RoHS and ISO 10993 standards adds credibility for regulated sectors. For engineers prioritizing both precision and durability, this is a benchmark product."

Linda Park - CNC Process Optimization Specialist

"I’ve consulted for over 30 machining shops, and material consistency is often the bottleneck. juli’s 0.2mm tolerance specification is reliably met, reducing post-processing time by up to 40%. The customizable thickness and fiber alignment options allow shops to tailor blanks for specific toolpaths and load directions—this isn’t just off-the-shelf material, it’s a performance-optimized solution."

Posted: 2 days ago

"Used the Advanced Model for our delivery drone arms. The stiffness-to-weight ratio is unmatched. First flight tests show 18% longer battery life thanks to reduced mass. CNC machining was flawless—no chipping or delamination."

Posted: 1 week ago

"Integrated into a small satellite bracket assembly. Survived thermal vacuum testing with no dimensional shift. Custom thickness option was key. Will be reordering for next phase."

Posted: 3 weeks ago

"Base Model worked perfectly for my RC plane fuselage. Light, strong, and arrived with clean edges. Slight variation in surface gloss between sheets, but structurally identical."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.