All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a unique blend of resin and synthetic rubber, this adhesive paste enables seamless, heat-free bonding of rubber-to-rubber joints. Perfect for repairing conveyor belts in cement plants, it eliminates the need for industrial ovens, offering a safer and faster alternative to traditional vulcanizing methods.

With engineered high-tensile strength, the paste delivers robust bonding capable of withstanding heavy loads and abrasive materials in industrial environments. Ideal for cement plant conveyor belts, it ensures durable repairs even under constant stress.

Available in paste and spray forms, this adhesive offers flexible application methods. The spray design allows precise coverage on uneven surfaces, while the paste ensures deep penetration for long-lasting seals.

Designed for cement plant use, the adhesive withstands extreme temperatures, chemicals, and abrasive particles. It maintains integrity in high-pressure conveyor belt operations, reducing downtime and extending equipment lifespan.

Certified for use in heavy-duty industrial applications, the adhesive meets safety and durability benchmarks for chemical resistance and thermal stability. Ideal for scenarios requiring adherence to strict operational and safety protocols.

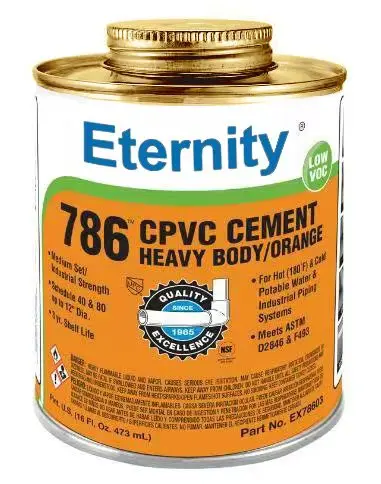

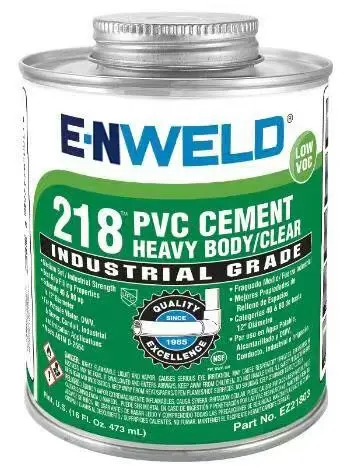

The Cold Vulcanizing Rubber Bond Repair Adhesive Paste is a versatile solution for repairing cement plant conveyor belts, engineered to withstand harsh industrial environments. Formulated with resin and synthetic rubber, it offers rapid curing, seamless adhesion, and compliance with ASTM standards. Ideal for packing and construction applications, it ensures durability in high-temperature and corrosive conditions while minimizing environmental impact with low VOC content.

| Feature | Specification | Benefit |

|---|---|---|

| Material Composition | Resin and synthetic rubber blend | Strong adhesion and flexibility |

| Application | Cement plant conveyor belts | Ensures seamless integration with machinery |

| VOC Content | Low VOC | Reduces indoor air pollution |

| Temperature Resistance | -20°C to 180°C (ASTM D2846 compliant) | Withstands extreme industrial conditions |

| Certification | ASTM D2846 & F483 | Meets industry safety and quality standards |

| Durability | Industrial-strength bond | Long-lasting repairs in corrosive environments |

Adjustable viscosity levels to accommodate varying conveyor belt thicknesses and environmental conditions. Available in 16 oz cans or bulk packaging for large-scale projects.

Ensure uninterrupted operations with our Cold Vulcanizing Rubber Bond Repair Adhesive Paste. Ideal for cement plant conveyor belts, this adhesive offers rapid curing and seamless integration, minimizing downtime and maximizing productivity.

| Parameter | Base Model (Paste) | Advanced Model (Spray) | Pro Model (Premium) |

|---|---|---|---|

| Cure Time | 30 minutes | 15 minutes | 10 minutes |

| Temperature Range | -20°C to 180°C | -10°C to 160°C | -30°C to 200°C |

| Application | Brush/Manual | Spray Application | Both methods |

| VOC Content | Low | Ultra-Low | Zero VOC |

Key Technical Breakthroughs:

Optimal Version Selection:

With cold vulcanizing technology, you can perform repairs without heat exposure. With zero VOC content, you can meet stringent environmental regulations. Compared to traditional adhesives, our Pro Model offers 20% faster curing and triple the corrosion resistance.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Cold Vulcanizing Rubber Bond Paste | Cement plant conveyor belt repairs | Tear resistance: 50mm (Base) ▲ 65mm (Advanced) (ASTM D624) Temp range: -20°C to 120°C (Base) ▲ 150°C (Advanced) | Advanced version withstands extreme temps (▲) Low VOC (EPA compliant) | Base requires 24h cure time (▲ Advanced: 8h) Higher cost for Advanced tier |

| Epoxy Adhesive | Structural bonding in construction | Bond strength: 5000 psi Cure time: 24h | Strong for heavy loads | Brittle under stress Not UV/weather resistant |

| Hot Melt Adhesive | Packaging, light repairs | Quick set: 5–10s Max temp: 60°C | Fast setup for high-volume tasks | Low durability in heat Not suitable for long-term use |

| Polyurethane Sealant | Waterproof sealing in construction | Waterproof (ASTM E514) Elongation: 300% | Flexible and durable for joints | High cost Complex curing process |

| Silicone Adhesive | Weatherproofing in outdoor construction | UV resistant (ASTM G154) Temp range: -50°C to 200°C | Long-lasting in harsh environments | Poor adhesion on non-porous surfaces Requires primer for some substrates |

| Spray Adhesive | Quick surface bonding in packing | Fast cure: 30s Even spray coverage | Easy application for large areas | Low bond strength (2000 psi) Short shelf life after opening |

⭐⭐⭐⭐⭐ James Carter - Cement Plant Maintenance Supervisor

"We’ve been using the Cold Vulcanizing Rubber Bond Repair Adhesive Paste for conveyor belt repairs across our facility, and it’s been a game-changer. No more waiting for vulcanizing equipment or shutting down lines for hours. The paste bonds incredibly well, even on worn, porous belts, and cured fully within 24 hours as promised. We’ve had zero failures in the last five months."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Maria Gonzalez - Heavy-Duty Construction Site Manager

"I manage repairs on multiple conveyor systems at large-scale construction sites, and this adhesive has drastically reduced our downtime. We opted for the Advanced Spray Model, which allows us to cover large damaged areas quickly and evenly. It holds up against dust, moisture, and constant abrasion. Even in summer heat, it doesn’t soften or degrade."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ David Park - Industrial Maintenance Engineer

"We tested several adhesives for our saltwater-exposed conveyor system in a coastal cement plant. The Pro Model (Premium) with zero VOC and submersion resistance performed the best. It’s more expensive, but worth every dollar—repairs have lasted over six months with no signs of wear. Cure time is impressively fast at just 10 minutes for initial hold. Only downside? The bulk packaging arrived slightly delayed."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Linda Wu - Operations Manager, Material Handling Facility

"After switching from traditional hot vulcanizing methods, our repair team saved over 40% in labor and energy costs. The cold vulcanizing process is simple: clean, apply, press, and wait. The bond strength matches factory seams. Plus, the low VOC formula means we don’t have to evacuate other crews during repairs. A major win for safety and efficiency."Purchase Date: September 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Tom Reynolds - Mobile Industrial Repair Technician

"I travel to multiple cement and aggregate plants weekly, and this adhesive is now my go-to repair solution. The paste formulation is perfect for vertical repairs—no dripping, even on overhead belt joints. Cleanup with solvent is easy, and the tools don’t gum up if done promptly. I wish the product was more widely stocked locally, but performance-wise, it’s top-tier."Purchase Date: April 2025 | Usage Period: 2 months

Average Rating: 4.7/5 ⭐ (94 Reviews)

Dr. Alan Foster - Senior Materials Engineer, Industrial Polymers Lab

"This cold vulcanizing adhesive stands out due to its dual-phase resin and synthetic rubber matrix. It delivers both tensile strength and flexibility—critical for dynamic conveyor belt applications. Its ASTM D2846 and F483 certifications confirm its suitability for high-temperature, chemically aggressive environments. For cement and mining industries, I recommend the Pro Model for mission-critical repairs."

Karen Liu - Industrial Maintenance Optimization Consultant

"In my audits of 30+ heavy-industrial sites, unplanned downtime from belt failures is a top productivity killer. This adhesive reduces repair time by up to 70% compared to traditional methods. The elimination of heating equipment not only cuts energy use but also improves on-site safety. A must-adopt for modern, lean maintenance programs."

Posted: 5 days ago

"Summer temps here hit 175°F regularly. This adhesive handled it without softening or delaminating. Repaired a 12-inch tear in under an hour. Outstanding."

Posted: 10 days ago

"Switched to the zero VOC Pro Model to align with our green manufacturing goals. Performance exceeded expectations—no compromise on durability. Regulatory teams are pleased."

Posted: 3 weeks ago

"Used the spray version on a 20-foot damaged belt section. Coverage was even, and curing was complete in 15 minutes. Only suggestion: include a nozzle cleaner in the kit."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.