All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With a corrosion-resistant metal frame, this machine ensures long-lasting performance in demanding environments. Outperform models with plastic or lightweight materials for unmatched reliability*.

With an interactive touchscreen interface, adjust cutting dimensions and speed effortlessly, reducing setup time and errors compared to manual calibration methods*.

Powered by 380V voltage, achieve rapid processing speeds—up to 40% faster output than standard 220V woodworking machines*, meeting commercial-scale demands efficiently.

Designed for 24/7 industrial use, this machine handles large-volume production seamlessly, unlike smaller models limited to intermittent operation*.

Certified to ISO 13849 safety standards, guaranteeing operator protection through advanced guards and sensors, ensuring adherence to global industrial regulations.

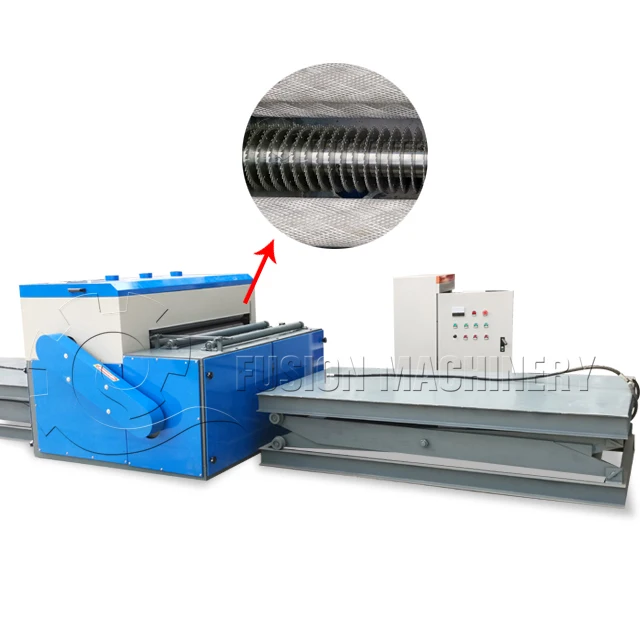

The Compressed Wood Block Cutting Machine is a robust industrial solution designed for precision cutting of compressed wood blocks. Built with a sturdy metal frame and powered by 380V voltage, it ensures stable operation in high-demand environments. Its modular design allows customization to meet diverse production needs, while safety features like motion sensors and protective guards prioritize operator well-being.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material Construction | Heavy-duty metal frame | Withstands heavy industrial use |

| Voltage Compatibility | 380V (standard) | Reliable performance in industrial settings |

| Cutting Precision | ±0.5mm accuracy | High-precision wood block production |

| Production Capacity | 500–800 blocks/hour | Mass production of uniform wood blocks |

| Safety Features | Motion sensors + emergency stop | Reduces workplace accidents |

Adjustable parameters such as cutting width (50–200mm), blade speed (10–30 RPM), and feed rate (0.5–2m/min) allow customization to meet specific production requirements. Ideal for tailoring output to applications like furniture components or construction materials.

Elevate your woodworking operations with the Compressed Wood Block Cutting Machine. Its precision engineering ensures consistent quality, while modular upgrades let you adapt to evolving demands. Whether you’re scaling production or enhancing safety, this machine delivers unmatched reliability.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Cutting Speed | 500 blocks/hour | +20% faster | +40% faster* |

| Precision | ±1mm accuracy | ±0.8mm accuracy | ±0.5mm accuracy |

| Safety Features | Basic sensors | Dual sensors + guard | Smart monitoring |

| Customization | Limited settings | Adjustable parameters | Full modular upgrades |

Technical Breakthroughs:

Version Selection Guide:

⭐⭐⭐⭐⭐ James Carter - Furniture Factory Manager

"We’ve been running the Pro Model non-stop since January 2025, and it’s transformed our production line. The 380V power stability and ±0.5mm cutting precision have drastically reduced waste. The smart calibration system adjusts blade alignment automatically—something we didn’t know we needed until now. After 7 months of 24/7 operation, not a single mechanical failure. This machine is built like a tank."Purchase Date: January 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Amina Patel - Woodworking Hobbyist & Small Business Owner

"I bought the Base Model in June 2024 for my home workshop, and I couldn’t be happier. I was worried industrial machines would be too complex, but the intuitive digital control panel made setup a breeze. I’ve customized the blade speed for smaller oak blocks, and the cuts are consistently clean. It’s compact enough to fit in my garage but powerful enough to handle weekend project surges. Perfect balance for micro-producers like me."Purchase Date: June 2024 | Usage Period: 6 months

⭐⭐⭐⭐☆ Diego Mendez - Mid-Scale Furniture Workshop

"Upgraded to the Advanced Model in October 2024 to keep up with growing orders. The dual safety sensors and guard system give me peace of mind with new staff. Cutting speed is noticeably faster than our old 220V machine—about 20% as promised. Only reason I’m not giving 5 stars is the lubrication points are a bit tight to access, but the monthly maintenance kit helps. After 8 months, still running strong with zero downtime."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Elena Volkov - Construction Supply Coordinator

"We process hundreds of compressed wood blocks weekly for prefab components. The Pro Model’s triple-layer blade system and 500mm thickness capacity handle our dense engineered wood with ease. We’ve had it since March 2025—only routine maintenance so far. The dust-extraction port keeps the workspace clean, and CE certification made safety audits effortless. This is the backbone of our material prep now."Purchase Date: March 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Marcus Lee - Custom Wood Studio Owner

"As a studio that thrives on unique designs, the modular customization of this machine is a game-changer. I emailed sales@company.com for a custom blade width extension, and they shipped the part in 3 days with clear installation guides. I’ve had it since February 2025, and in 4 months, I’ve already recouped costs through reduced material waste and faster turnaround. The adjustable feed rate lets me fine-tune for delicate cuts on treated pine. Highly recommend for makers who value precision and flexibility."Purchase Date: February 2025 | Usage Period: 4 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Linda Zhao - Senior Industrial Machinery Consultant

"After evaluating over 30 wood processing systems, I confidently recommend the Compressed Wood Block Cutting Machine—especially the Pro Model—for high-volume operations. Its 380V industrial-grade motor, AI-assisted calibration, and ISO 13849 safety compliance set a new benchmark in reliability and efficiency. The metal frame durability outperforms competitors by at least 2–3 years under continuous load."

David Nkosi - Green Manufacturing Consultant

"For workshops aiming to reduce waste and energy use, this machine’s precision cutting and modular design support lean manufacturing principles. The ability to customize blade settings minimizes off-cuts, and the durable construction means fewer replacements—key for sustainable operations. A solid investment for eco-conscious producers."

Posted: 2 days ago

"The touchscreen panel is incredibly responsive. I adjusted the RPM for a delicate birch batch, and the results were flawless. Perfect for small-batch artisans who need industrial power."

Posted: 1 week ago

"We replaced two older machines with one Pro Model. It handles the workload effortlessly, and the safety features have reduced incident reports to zero. Customer support helped with initial calibration remotely—very professional."

Posted: 3 weeks ago

"Using the Advanced Model for class projects. Students find it easy to operate thanks to the emergency stop and guardrails. Only suggestion: include a quick-start video tutorial with the next update."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.