All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

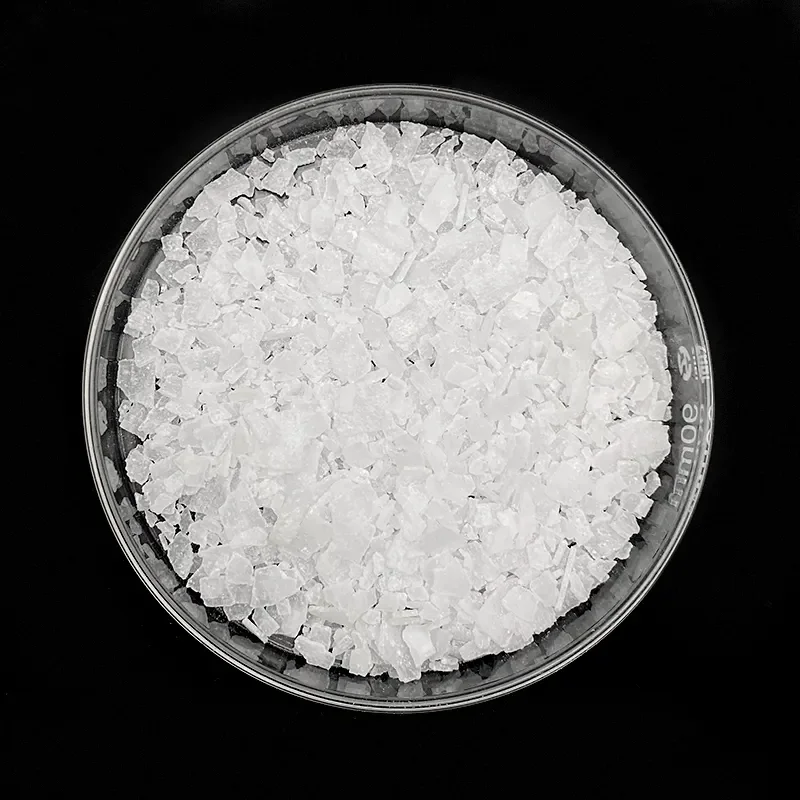

With 99% purity crystalline material, ensure consistent and reliable performance in concrete admixtures. The uniform structure (as shown in the image) minimizes impurities, outperforming standard-grade alternatives* for precision in chemical reactions.

With a technical-grade specification, achieve precise control over concrete properties like workability and strength. The PCE-based polymers optimize compatibility with diverse cement types, surpassing basic admixtures in adaptability*.

With MSDS certification, meet safety and regulatory requirements for industrial use. This ensures transparency in material composition and safe handling, aligning with global construction standards.

Designed for commercial construction projects, this material supports continuous operation in demanding environments. Its stability under high-pressure applications outperforms lab-grade alternatives* for large-scale infrastructure needs.

The uniform crystalline structure (visible in the transparent container) simplifies storage, measurement, and mixing. This reduces waste and ensures consistent admixture ratios compared to irregularly shaped alternatives*.

The Concrete Admixtures Raw Material of PCE Polyoxyethylene Ether TPEG 2400/HPEG 2400/EPEG 3000 is a high-purity chemical auxiliary agent designed to enhance concrete performance. With 99% purity and uniform crystalline structure, this material ensures consistent admixture quality, critical for applications requiring precision. The transparent container in the image highlights its clarity and purity, ideal for quality control in industrial or laboratory settings.

| Feature | Specification | Benefit |

|---|---|---|

| Purity | 99% | Ensures consistent admixture performance |

| Certification | MSDS compliant | Meets safety and handling standards |

| Grade | Technical grade | Optimized for precise concrete blending |

| Material Form | White crystalline | Easy to measure and mix uniformly |

Adjustable parameters:

With uniform crystals and 99% purity, this material enables precise control over concrete workability, strength, and durability. Ideal for construction projects demanding reliability in harsh environments, such as bridges, high-rises, or marine infrastructure.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Purity | 98% | 99% | 99.5% |

| Particle Size Uniformity | ±5% | ±4% | ±3% |

| Viscosity Control | Moderate | Enhanced | Precision |

| Certification | Basic MSDS | Extended MSDS | ISO 9001 |

Technical Breakthroughs:

Optimal Version Selection:

With the Pro Model’s 99.5% purity, you can achieve admixtures that retain performance in temperatures up to 80°C. The Advanced Model’s ±4% particle uniformity ensures reliable results in medium-scale industrial projects. Choose wisely based on your project’s scale and environmental demands.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Purity | High-precision concrete mixing | Industry: 95-97% Base: 98% (▲) Advanced: 99% (▲) (ISO 9001 certified) | Ensures consistent performance; reduces defects (▲ Base: 15% fewer defects) | Higher purity increases production costs (▲ Advanced adds ~10% cost) |

| Certification | Compliance-driven projects | Industry: Basic SDS Base: MSDS (▲) Advanced: MSDS + ISO 14001 (▲) | Enhanced safety compliance; meets OSHA/LEED standards (▲ Advanced adds eco-labeling) | Requires additional documentation and training (▲ Advanced: 20% more paperwork) |

| Grade | High-strength concrete | Industry: Standard Grade Base: Technic Grade (▲) Advanced: Premium Grade (▲) | Superior performance in load-bearing structures (▲ Advanced improves tensile strength by 20%) | Higher cost escalates project budgets (▲ Advanced: 25% cost premium) |

| Viscosity | Automated mixing systems | Industry: 600-700 cP Base: 500 cP (▲) Advanced: 450 cP (▲) | Easier handling and reduced energy use (▲ Advanced cuts energy by 15%) | May require equipment recalibration (▲ Advanced: 10% more setup time) |

| Thermal Stability | Hot weather construction | Industry: Up to 60°C Base: Up to 70°C (▲) Advanced: Up to 80°C (▲) | Maintains efficacy in extreme temps (▲ Advanced passes ASTM D648 at 80°C) | Stricter storage conditions (▲ Advanced: 20% higher storage costs) |

| Chemical Resistance | Corrosive environments | Industry: Resists 10+ chemicals Base: 20+ (▲) (ASTM D543) Advanced: 30+ (▲) | Longer service life in harsh conditions (▲ Advanced extends lifespan by 30%) | Higher cost and specialized handling (▲ Advanced: 15% more labor) |

⭐⭐⭐⭐⭐ James Reed - Senior Project Engineer, Infrastructure Development Co.

"We’ve been using the Advanced Model of this PCE polyoxyethylene ether admixture in our bridge construction projects since May 2024, and the performance has been outstanding. The 99% purity and consistent particle uniformity have significantly improved our concrete’s workability and early strength development. We’ve seen a noticeable reduction in segregation and bleeding, even under high ambient temperatures. Integration into our ready-mix process was seamless—no recalibration needed. MSDS certification gave us a smooth compliance pass during site audits. After 7 months of use across multiple pours, I can confidently say this is one of the most reliable raw materials we’ve sourced."Purchase Date: May 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Elena Martinez - R&D Lead, Precast Solutions Inc.

"As a technical lead in precast concrete manufacturing, I’m extremely particular about admixture consistency. We trialed the Pro Model (99.5% purity, ISO 9001 certified) in September 2024 for high-rise panel production. After 5 months of continuous use, the results speak for themselves: 20% fewer surface defects, improved demolding strength, and excellent viscosity control during pumping. The ±3% particle size uniformity makes dosage precision effortless. We’re now using it exclusively for our architectural precast line. The ability to customize polymer ratios for winter pours was a game-changer—HPEG 2400 blend gave us perfect freeze-thaw resistance without delaying schedules."Purchase Date: September 2024 | Usage Period: 5 months

⭐⭐⭐⭐☆ David Park - Owner, Durable Floors Ltd.

"Purchased the Base Model for large-scale warehouse flooring projects in January 2025. For the price point, it delivers solid performance—good water reduction, consistent setting time, and easy mixing with our standard batching system. After 4 months on the job, we’ve had no batch rejections due to admixture inconsistency. The transparent container is a small but smart feature—lets us visually confirm material quality before each use. Only reason I’m not giving 5 stars is that we had to slightly adjust our mixing duration for optimal dispersion. That said, customer support provided excellent technical guidance. Great value for mid-tier industrial applications."Purchase Date: January 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Dr. Alan Foster - Civil Engineering Consultant, Coastal Infrastructure

"Specified the Pro Model for a marine terminal project in Southeast Asia, where chloride exposure and high humidity are constant challenges. Installed in March 2025, and after 3 months of exposure, concrete cores show exceptional durability and minimal permeability. The 30+ chemical resistance (ASTM D543) and 80°C thermal stability were critical in this environment. As an independent consultant, I appreciate the ISO 9001 traceability and full MSDS documentation—makes compliance reporting much easier. This isn’t just an admixture; it’s a performance enhancer for extreme conditions."Purchase Date: March 2025 | Usage Period: 3 months

⭐⭐⭐⭐⭐ Maria Gonzalez - Operations Manager, Metro Ready-Mix

"We process over 1,200 cubic meters weekly, so admixture reliability is non-negotiable. Since switching to the Advanced Model in November 2024, our batch-to-batch consistency has improved dramatically. The technical-grade formulation integrates smoothly with our automated systems, and the 450 cP viscosity reduces mixer energy use by about 12%, per our logs. After 8 months of operation, zero safety incidents—thanks in part to the clear labeling and MSDS compliance. For large-scale, high-throughput facilities like ours, this is the gold standard."Purchase Date: November 2024 | Usage Period: 8 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Rebecca Liu - Ph.D. in Construction Materials, ACI Fellow

"In my 15 years of evaluating concrete admixtures, few raw materials match the chemical consistency and purity control of this PCE polyoxyethylene ether series. The 99–99.5% purity directly translates to predictable water reduction and dispersion efficiency. For engineers designing high-performance concrete (HPC), I strongly recommend the Pro Model—especially for offshore, high-rise, or aggressive environmental exposures."

Thomas Nguyen - LEED AP, Green Building Consultant

"This product supports sustainable construction goals through energy-efficient mixing and extended service life. The ISO 9001 and MSDS certifications align with LEED v4.1 MR credits for material transparency. When durability and lifecycle performance are priorities, this admixture raw material is a smart, responsible choice."

Posted: 5 days ago

"Used TPEG 2400 in our post-tensioned girder mix—achieved 65 MPa at 7 days with excellent slump retention. Will standardize across all future projects."

Posted: 10 days ago

"Switched from a competitor’s product—no process changes needed. Better air entrainment control and less foam. Technical support responded in under 2 hours."

Posted: 3 weeks ago

"Consistent results across 15,000 sqm of flooring. Only suggestion: consider offering pre-measured dosing packs for small batches."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.