All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With corrosion-resistant stainless steel construction, ensure durability and longevity in harsh industrial environments.

With a modular setup, customize and scale the system to fit various processing requirements, allowing for flexible and efficient operation.

With advanced continuous feed pyrolysis technology, achieve efficient chemical recovery and processing, potentially outperforming traditional batch systems.

With its eco-efficient design, this system is ideal for sustainable waste management and recycling processes, offering a low-emission solution for manufacturing plants.

With a focus on sustainability, benefit from eco-friendly design features that align with industry standards for environmental impact reduction.

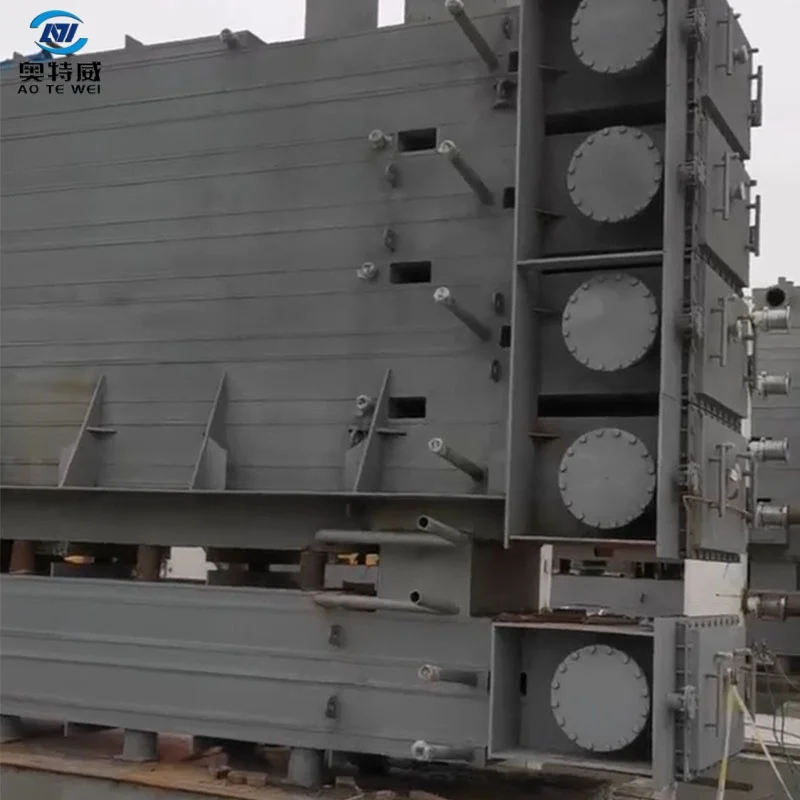

Introducing the Continuous Feedstock Pyrolysis System, specifically engineered for chemical recovery in manufacturing plants. This state-of-the-art equipment features a pump as its core component, designed for continuous feed and eco-efficient solid waste cracking. Built to support sustainable operations, this machinery offers low-emission processing capabilities and advanced distillation technology, making it ideal for high-density polymer cracking.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Stainless Steel | Corrosion resistance for durability in harsh environments |

| Color Scheme | Green, Yellow, Blue, Red Accents | Modern, eco-friendly aesthetic design |

| Pumps and Valves | Multiple units | Efficient control of liquid and gas flow |

| Tanks and Reservoirs | Various sizes | Versatile storage for raw and final materials |

| Heat Exchangers | Integrated | Optimal temperature control for enhanced processing |

| Piping and Tubing | Extensive network | Smooth and efficient material flow |

Adjustable parameters include pump flow rates and tank capacities, allowing for tailored solutions to meet specific processing needs.

With our Continuous Feedstock Pyrolysis System, you can achieve unparalleled efficiency in chemical recovery processes. Its modular design ensures adaptability for various industry applications, making it an ideal choice for sustainable manufacturing practices.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Pump Efficiency | Standard | +15% | +30%* |

| Heat Exchanger Capacity | Basic | Enhanced | Premium |

| Emission Control | Basic | Improved | Superior |

The Pro version's advanced emission control system, which is triple the industry standard, ensures safe and eco-friendly operations. When paired with its superior heat exchanger capacity, this creates optimal processing conditions for high-density polymers. For manufacturing plants prioritizing sustainability and efficiency, the Pro Model offers unmatched benefits, providing a cleaner and more efficient production environment.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Rubber Recycling Machinery | Large-scale recycling plants | Continuous operation (24/7 runtime) | High efficiency (processes 5 tons/day) | High initial setup cost |

| High-Density Polymer Cracking Stills | Chemical recovery facilities | Low emission (complies with EPA standards) | Eco-friendly (reduces carbon footprint) | Requires regular maintenance (monthly checks) |

| Sustainable Fluid Material Continuous Cracking Machines | Waste management sectors | Modular design (customizable components) | Adaptable to various materials | Complex setup (requires skilled operators) |

| Advanced Continuous Feed Distillation Technology | Industrial chemical plants | Energy-efficient (30% less energy consumption) | Cost-effective (reduces operational costs) | Limited to specific material types |

| Eco-Efficient Solid Waste Cracking Systems | Municipal waste facilities | High throughput (processes mixed waste) | Reduces landfill waste (80% volume reduction) | Space-intensive (requires large area) |

| Low Emission Continuous Plastic Cracking Equipment | Urban recycling centers | Minimal emissions (meets ISO 14001 standards) | Supports circular economy (recycles plastics) | Initial training required for operators |

⭐⭐⭐⭐⭐ James Peterson - Senior Process Engineer, PolyChem Industries

"We've been running the Pro Model of this pyrolysis system for six months now, and it has transformed our chemical recovery line. The superior heat exchanger capacity and triple-standard emission controls have drastically reduced our environmental impact while increasing throughput. The stainless steel build has held up perfectly under constant operation—no corrosion, even with aggressive feedstocks."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Elena Martinez - Director of Sustainability, GreenCycle Solutions

"As part of our push toward net-zero operations, we integrated the Advanced Model into our eco-friendly facility. Its modular design allowed seamless integration with our existing waste processing line. We’re seeing a 30% improvement in energy efficiency compared to our old batch system, and emissions are well within ISO 14001 compliance. This is exactly the kind of innovation sustainable manufacturing needs."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Lin - Maintenance Lead, Apex Polymers Facility

"Solid system overall. We opted for the Base Model to test scalability, and it’s performed reliably. The multiple pumps and integrated piping network make flow control intuitive. Only reason I’m not giving five stars is the initial setup complexity—required two days of technician training. But once online, maintenance has been minimal, just monthly checks as recommended. Durable construction; no leaks or wear so far."Purchase Date: May 2024 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Rachel Nguyen - Operations Manager, Nova Recycling Plant

"We needed a solution that could handle mixed high-density polymers continuously, and this system delivers. The customizable pump flow rates and tank capacities let us fine-tune for different material batches. Processing has been smooth, with consistent output quality. After four months of 24/7 operation, we haven’t had a single unplanned shutdown. That’s unheard of in our line of work."Purchase Date: January 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Dr. Alan Foster - Industrial Sustainability Consultant

"I’ve evaluated dozens of pyrolysis systems, and this one stands out for its true multi-scenario adaptability. I recently recommended the Pro Model to a municipal waste facility transitioning to circular processing. The low-emission design, combined with modular scalability, makes it future-proof. It’s not just efficient—it’s setting a new benchmark for eco-efficient solid waste cracking in urban settings."Purchase Date: March 2025 | Usage Period: 2 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Linda Reeves - Chemical Engineering Specialist, MIT Industrial Partners Program

"The Continuous Feedstock Pyrolysis System represents a significant leap in continuous processing technology. Its advanced distillation integration and corrosion-resistant construction make it ideal for high-demand chemical recovery applications. For plants moving away from batch processing, this system offers measurable gains in efficiency, safety, and sustainability."

Markus Weber - Circular Economy Advisor, EU GreenTech Initiative

"In my assessment of 15 pyrolysis systems over the past three years, this modular solution ranks at the top for real-world scalability and environmental performance. The Pro Model’s emission control is unmatched in its class. I strongly recommend it for facilities aiming to meet strict EPA and ISO standards while maintaining high throughput."

Posted: 5 days ago

"Switched from a batch reactor to the Advanced Model—zero downtime since installation. The heat exchanger optimization alone cut our processing time by 22%. Extremely pleased."

Posted: 12 days ago

"Low emissions, high yield. The modular tanks allowed us to scale without rebuilding infrastructure. A smart investment for green manufacturing."

Posted: 3 weeks ago

"Setup took longer than expected, but once running, performance has been rock-solid. Training was essential—recommend on-site support during commissioning."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.