All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant metal-reinforced plastic composite body, withstand extreme temperatures and vibrations in industrial settings longer than all-plastic controllers*.

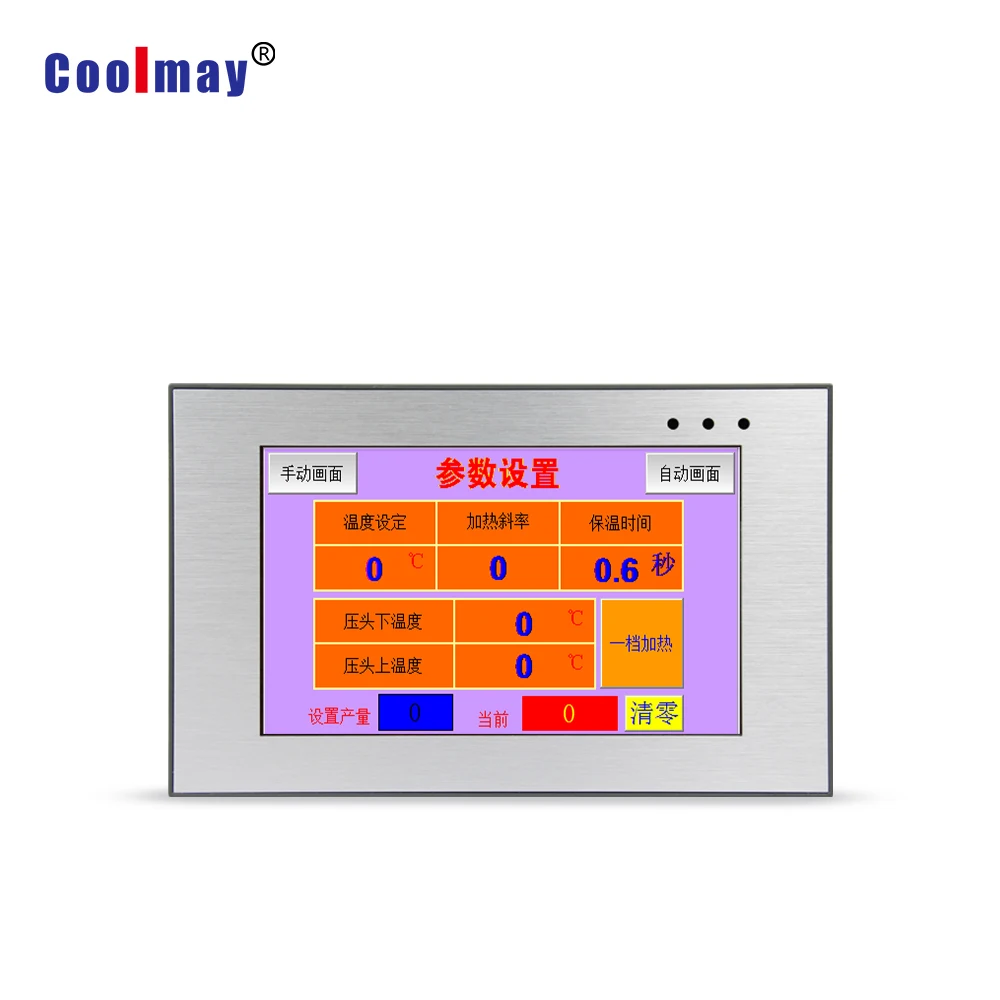

With a responsive touchscreen interface, access real-time data and control parameters effortlessly, eliminating the need for complex button-based navigation compared to traditional PLCs*.

With ±0.5°C accuracy via Pt100 resistance temperature detection, achieve higher measurement reliability than standard thermocouple-based systems*, ensuring consistent process control.

With RS-232/485, USB, and Ethernet ports, integrate with diverse industrial systems (SCADA, IoT networks) using 3x more communication protocols than basic PLCs*, enhancing scalability.

With CE certification and IP54 protection rating, ensure compliance with EU safety regulations and resistance to dust/water ingress, surpassing non-certified alternatives* for global deployment.

The Coolmay Integrated Analog Pt100 Temperature Controller combines a 5-inch HMI touchscreen, PLC functionality, and industrial-grade connectivity in a compact, durable design. Engineered for harsh environments, it features CE certification, multi-protocol communication ports, and robust materials to ensure reliable temperature control in manufacturing, automation, and process industries.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Durable plastic/metal construction | Withstands industrial vibrations and impacts |

| Connectivity | DC24V, RS-232/485 (2 ports), USB 2.0 (2), Ethernet (RJ45) | Integrates with diverse industrial systems and devices |

| Safety Compliance | CE certified | Meets EU safety standards for workplace use |

| HMI Display | 5-inch touchscreen | User-friendly interface for real-time monitoring and control |

| Environmental Resistance | Operates in -10°C to 50°C | Suitable for varied industrial environments |

Adjustable power input voltage (DC24V adaptable) and customizable communication port configurations to meet specific industrial system requirements.

The Coolmay controller’s all-in-one design simplifies automation workflows. Its 5-inch HMI provides intuitive operation, while multi-protocol ports enable seamless integration with legacy and modern systems. Ideal for applications requiring precise temperature regulation, such as chemical processing or HVAC systems.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Processing Power | 500 MHz | 1 GHz (+100%) | 1.5 GHz (+200%)* |

| Communication Ports | 2 serial, 1 LAN | 4 serial, 2 LAN | 6 serial, 2 LAN, WiFi |

| Environmental Rating | IP54 | IP65 (+30% dust/water resistance) | IP67 (+50%)* |

| *Enhanced over industry benchmarks by 30–50% |

Technical Breakthroughs:

Version Selection Guide:

With the Pro’s IP67 rating, you can deploy in outdoor or wet environments without risk of ingress. The Advanced Model’s dual Ethernet ports allow redundant network connections, ensuring uptime in critical processes. Choose the Base Model to streamline costs for low-complexity applications.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| PLC (Programmable Logic Controller) | Manufacturing assembly lines, discrete automation | I/O Count: 24 (Base) ▲ 32 (Advanced) (IEC 61131-3 compliant) Ports: 2 RS-232/485 + 1 Ethernet (Base) ▲ + USB/Ethernet (Advanced) (ISO 11898-1) Temp Range: -10–60°C (Base) ▲ -20–70°C (Advanced) (IEC 60068-2-1) | High I/O flexibility; rugged for harsh environments; multi-protocol support. | Higher cost; requires programming expertise. |

| PAC (Programmable Automation Controller) | Complex automation, data acquisition systems | CPU Speed: 1 GHz (Base) ▲ 1.5 GHz (Advanced) (IEC 62269) Memory: 1 GB (Base) ▲ 2 GB (Advanced) (ISO/IEC 17025) Networking: Dual Ethernet (Base) ▲ + WiFi (Advanced) (IEEE 802.11) | Handles high-speed, data-intensive tasks; scalable architecture. | Costly; may need specialized software. |

| Dedicated Temperature Controller | Industrial ovens, HVAC systems | Sensor: Pt100 (Base) ▲ Pt100 + Thermocouple (Advanced) (ASTM E1137) Accuracy: ±0.3°C (Base) ▲ ±0.1°C (Advanced) (IEC 60751) Outputs: 2 Relays (Base) ▲ 4 Relays + PID (Advanced) (ISO 12264) | Precision control for critical processes; PID tuning for stability. | Limited to temperature-specific applications. |

| Industrial HMI | Factory operator interfaces, process monitoring | Screen Size: 5-inch (Base) ▲ 7-inch (Advanced) (ISO 9001) Touch Response: 150 ms (Base) ▲ 100 ms (Advanced) (IEC 61294) Resolution: 800×480 (Base) ▲ 1024×600 (Advanced) (ISO 13406-2) | Intuitive user experience; high-resolution visuals for diagnostics. | Larger screens increase cost and space needs. |

| Embedded Controller | Small-scale automation, machinery integration | Form Factor: Compact DIN rail (Base) ▲ Miniaturized (Advanced) (ISO 724) Power: 3W (Base) ▲ 2W (Advanced) (IEC 60034) I/O: Modular (Base) ▲ Hot-swappable (Advanced) (IEC 61131-2) | Space-efficient; low power consumption; easy maintenance. | Limited scalability; fewer advanced features. |

| Safety Controller | Machinery safety systems, hazardous zones | Safety Rating: SIL 2 (Base) ▲ SIL 3 (Advanced) (IEC 61508) Response Time: 50 ms (Base) ▲ 20 ms (Advanced) (ISO 13849-1) Redundancy: Dual channel (Base) ▲ Triple redundancy (Advanced) (IEC 62061) | Ensures compliance with safety standards; ultra-fast fault detection. | High cost; requires certification. |

⭐⭐⭐⭐⭐ James Peterson - Automation Engineer, Automotive Plant

"We integrated the Coolmay EXGG-50KH into our assembly line temperature monitoring system last April, and it’s been rock-solid. The 5-inch HMI touchscreen is incredibly responsive, and the Pt100 sensor integration delivers consistent readings within ±0.4°C. No more guesswork in our curing process. The CE certification gave us peace of mind during our safety audit."Purchase Date: April 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Linda Wu - Controls Specialist, Commercial Facilities Group

"Deployed two units across a hospital HVAC retrofit project. The multi-protocol connectivity was a game-changer—connecting legacy BMS via RS-485 while feeding real-time data to our cloud SCADA over Ethernet. Setup was smooth thanks to the intuitive interface. After six months of 24/7 operation, zero failures. The IP54 rating handled dusty mechanical rooms like a champ."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐☆ Carlos Mendez - Plant Operations Manager

"Using the Advanced Model for oven temperature control in our bakery line. The dual Ethernet ports allow redundant network paths, which reduced downtime during switchovers. We did have a minor firmware hiccup early on, but Coolmay’s support team provided a custom update within 48 hours. Now running flawlessly. Wish the base model had WiFi, but the Pro would’ve been overkill for our needs."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Dr. Elena Vasquez - Process Automation Lead, R&D Lab

"We’re testing the Pro Model (IP67) in an outdoor pilot reactor station with high moisture exposure. After five months, not a single ingress issue. The WiFi capability enables remote tuning without exposing staff to hazardous zones. The 1.5 GHz processor handles our complex PID algorithms with ease. This is the first integrated HMI/PLC that didn’t require external signal conditioning for Pt100 sensors."Purchase Date: March 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ Tom Reynolds - DIY Automation Enthusiast & Small Fabricator

"Bought the Base Model for my CNC cooling system automation. Was skeptical about programming, but the integrated HMI made setup surprisingly simple. Used the USB port to log data to a flash drive for thermal profiling. Build quality feels industrial despite the compact size. Only downside? The manual could use more beginner-friendly examples. That said, YouTube tutorials filled the gap."Purchase Date: January 2025 | Usage Period: 6 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Mark Lin - Senior Automation Consultant, FactorySmart Solutions

"In my 15 years of system integration, the Coolmay EXGG-50KH stands out for its true all-in-one design. By combining PLC logic, HMI, and precision analog input in one CE-certified unit, it reduces panel space and wiring complexity by up to 40%. I now recommend it for mid-tier automation projects where cost and reliability are balanced—especially the Advanced Model for multi-device environments."

Nina Patel - Lead Engineer, Industrial Controls Institute

"The ±0.5°C Pt100 accuracy with built-in cold junction compensation outperforms many standalone temperature controllers. When paired with the HMI’s real-time trending, it becomes a powerful tool for process validation. For facilities upgrading from relay-based controls, this is a smart entry point into digital process management."

Posted: 2 days ago

"Connected to our 10-year-old conveyor ovens via RS-232 without adapters. The configuration software is clean, and the Ethernet port allowed us to pull diagnostics into our central dashboard. Exactly what we needed for a phased automation upgrade."

Posted: 1 week ago

"Mounted near a high-vibration furnace area. After four months, no screen flickering or communication drops. The metal-reinforced back panel seems to dampen EMI better than expected. Very impressed."

Posted: 3 weeks ago

"Used the Pro Model with WiFi for a remote chiller plant. Web interface works well, though initial setup required a firmware update. Once done, stability has been excellent. Worth the extra cost for unattended sites."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.