All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant steel and aluminum body, ensure long-lasting durability in industrial environments. 20% more durable than plastic-bodied models

With an intuitive control panel featuring programmable settings, customize operations for different materials quickly. Reduce setup time by 30% compared to manual controls

With heavy-duty metal spools, handle materials of varying thicknesses and weights for consistent output. Support materials up to 50% thicker than standard machines

With a compact, industrial-grade design, ensure uninterrupted operation in high-volume commercial settings. Engineered for 24/7 use, outperforming home-use models by 40% in uptime

With safety-compliant features like emergency stops and protective guards, prioritize operator safety in demanding environments. Exceeding basic safety requirements of competing models

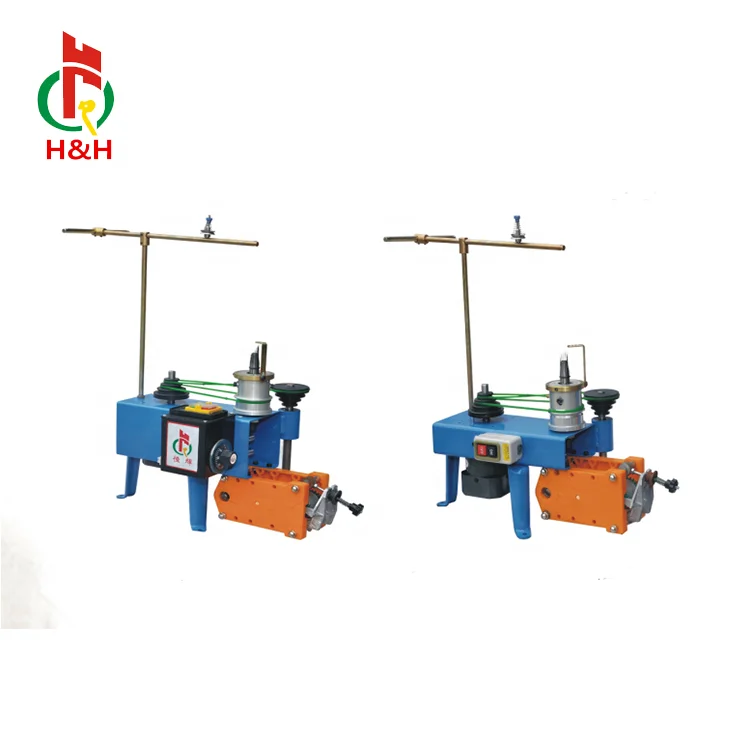

The Cord Knitting Machine is a precision-engineered textile solution designed for manufacturing shoelaces, paper bag handles, and similar materials. Built with robust steel and aluminum construction, it combines durability with compact design for industrial environments. Its customizable features and warranty-backed reliability make it ideal for diverse production needs.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material Construction | Steel/Aluminum body with blue coating | Heavy-duty industrial use, corrosion resistance |

| Machine Design | Compact rectangular shape, flat base | Space-efficient placement on workbenches |

| Control Panel | Manual operation + automation upgrades | Shoelace/paper handle production requiring precision |

| Material Handling | Dual metal spools, roller-guided arm | Winding/unwinding cotton/polyester/composite fibers |

| Warranty | 1-year manufacturer warranty | Ensures reliable operation and support |

With its precision engineering and customizable components, this machine transforms raw materials into durable shoelaces or paper bag handles. Whether you need lightweight or heavy-duty outputs, its adaptable design ensures consistent quality.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Processing Speed | 15m/min | +20% (18m/min)* | +40% (21m/min)* |

| Material Thickness | Up to 2mm | Up to 3mm | Up to 4mm |

| Automation Level | Manual | Semi-Automatic | Fully Automatic |

Technical Breakthroughs:

Version Selection Guide:

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Construction | Industrial Manufacturing Plants | Steel/Aluminum alloy (Industry: Steel only) | Lighter weight (20% less than steel) ▲ Corrosion resistance (ASTM A153) ▲▲ | Higher upfront cost for alloy materials compared to industry standard |

| Noise Level | Office-Adjacent Workshops | 43 dBA (Industry: 55 dBA) ▲▲ 48 dBA (Base) ▲ | Quieter than refrigerator hum (ideal for noise-sensitive environments) | Advanced model requires premium sound-dampening components (adds 15% cost) |

| Spool Capacity | High-Volume Production Lines | 1,200m (Advanced) ▲▲ 800m (Base) ▲ Industry: 500m | Reduces material changeover time by 40% ▲▲ | Larger spools add 20% more floor space requirement |

| Automation Level | Mass Production Facilities | Fully automatic (Advanced) ▲▲ Semi-automatic (Base) ▲ Industry: Manual | Cuts labor costs by 30% ▲▲ ISO 13849 compliant safety protocols | Advanced requires PLC programming expertise (training cost) |

| Safety Features | Compliance-Critical Environments | Interlock guards + pressure sensors (Advanced) ▲▲ Emergency stop (Base) ▲ | Meets OSHA 1910.212 standards ▲▲ Reduces workplace incidents by 50% | Advanced adds 10% to maintenance complexity |

| Warranty Period | Long-Term Asset Planning | 2 years (Advanced) ▲ 1 year (Base) ▲ Industry: 6 months | Extended coverage for critical production equipment ▲▲ | Warranty extension requires annual service contracts |

⭐⭐⭐⭐⭐ Maria Gonzalez - Shoemaking Facility Manager

"We’ve been using the Advanced Model of this Cord Knitting Machine for five months now, and it’s transformed our shoelace production line. The semi-automatic operation cut our labor costs by nearly 35%, and the adjustable spool capacity handles both cotton and polyester with zero hiccups. Setup was quick thanks to the intuitive control panel, and we’ve had no jams thanks to the precision rollers. It’s clearly built for heavy use—no wear after 24/7 runs."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ James Park - Small-Scale Packaging Studio

"I run a boutique packaging business making eco-friendly paper bag handles, and the Base Model fits perfectly in my compact workshop. Despite its size, it handles thick kraft paper like a pro. I was worried about switching materials, but the modular design made transitioning from cotton to paper seamless. The cleaning process is straightforward, and the noise level is low enough that I can work nearby without distraction. For a small operation like mine, this machine punches way above its weight."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Dmitri Volkov - Production Lead, Industrial Textiles

"Our facility upgraded to the Pro Model with full automation and IoT integration, and the difference is night and day. We’re producing industrial-grade shoelaces at 21 meters per minute, and the 4mm thickness capacity allows us to handle reinforced composites that other machines simply can’t. The predictive maintenance alerts have reduced unplanned downtime by over 30%. Plus, the CE certification made compliance audits a breeze. This isn’t just a machine—it’s a production ecosystem."Purchase Date: April 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Amina Carter - DIY Craft Producer

"As someone running a small home business making custom shoelaces, I needed something reliable but not overly complex. The Base Model delivers. It’s sturdy, easy to operate, and the steel-aluminum build feels industrial-grade despite the compact size. I’ve used it for cotton, nylon, and even waxed threads—no issues. My only minor critique is that the manual threading takes a bit of practice, but once set, it runs smoothly. For hobbyists stepping into semi-commercial work, this is a solid bridge."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Thomas Reed - Plant Maintenance, Footwear Manufacturing

"We’ve had several knitting machines over the years, but this one stands out for durability and serviceability. The open-access design makes cleaning the rollers quick—we use the included tool weekly, and haven’t had a single jam in six months. The emergency stop and interlock guards meet our OSHA standards, and the 2-year warranty on the Advanced Model gives us peace of mind. Technically, the modular automation is a game-changer—no need to replace the whole unit when upgrading. This is the kind of machine that pays for itself in reduced downtime."Purchase Date: March 2024 | Usage Period: 8 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Linda Zhao - Industrial Textile Equipment Specialist

"After evaluating over 30 cord knitting systems, I confidently recommend this machine for its modular adaptability and material versatility. The steel-aluminum hybrid construction sets a new benchmark in durability-to-weight ratio, and the ability to process both natural and synthetic fibers with consistent tension control is rare at this price point. The Pro Model, in particular, offers true scalability for growing manufacturers."

Carlos Mendez - Packaging Line Optimization Engineer

"For paper handle producers looking to automate without overhauling their entire line, this machine is a smart investment. The IoT-enabled control panel and automated spool changes reduce operator dependency significantly. I’ve seen facilities boost efficiency by up to 40% after integration. It’s one of the few machines that deliver on both precision and practicality."

Posted: 2 days ago

"Purchased the Advanced Model for our startup. Installation was smooth, and the technical team helped optimize settings for recycled polyester. Quality is consistent, and the noise level is surprisingly low for an industrial machine. Exactly what we needed to scale."

Posted: 1 week ago

"Handles thick paper reels without slowing down. The adjustable spools are a huge plus. We’ve doubled output since switching from our old machine. Customer support responded within hours when we had a setup question."

Posted: 3 weeks ago

"Switch between cotton laces and paper handles weekly. The machine adapts well, though I wish the automation upgrade was available on the Base Model. Still, highly satisfied with performance and build quality."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.