All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

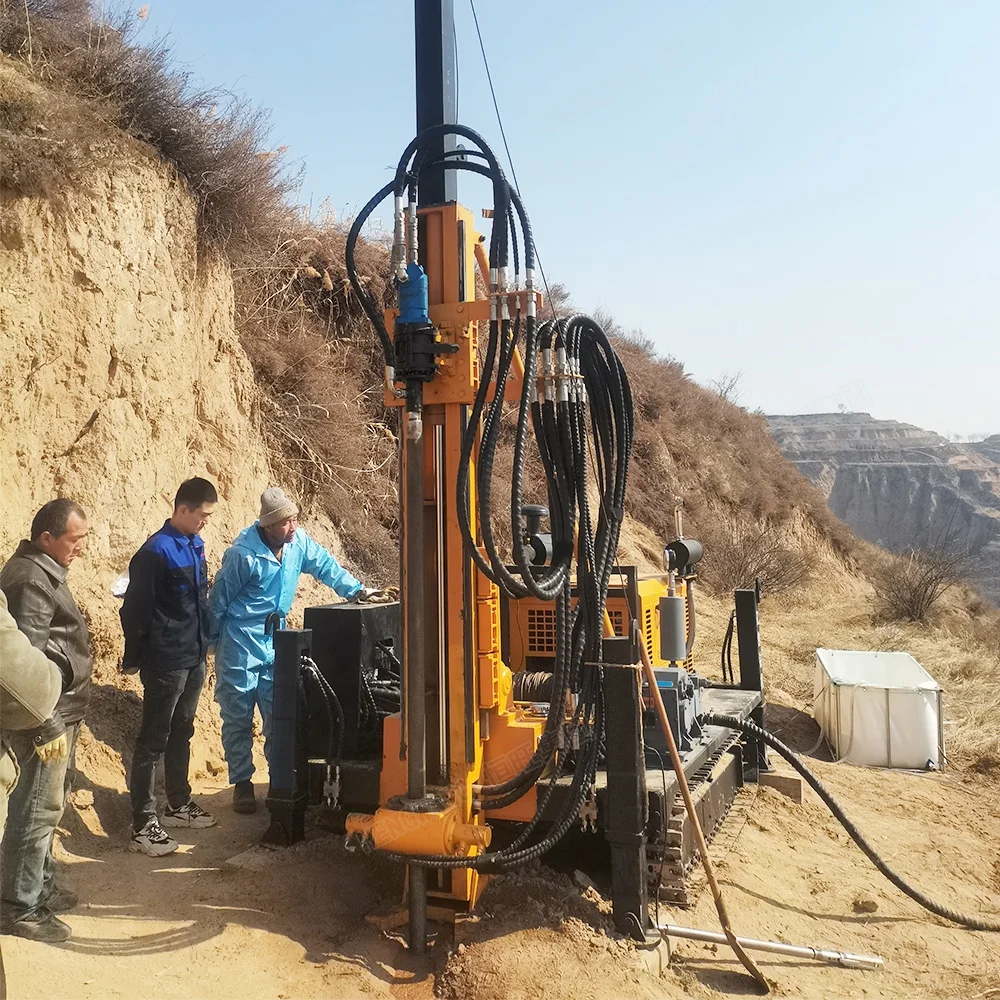

With a robust corrosion-resistant metal body and tracked undercarriage, you can ensure durability and stability on rugged terrains. The tracked design provides ~30% better traction than wheeled models*, enabling operation in wetlands, soft soils, and uneven surfaces.

With intuitive control panels and hydraulic systems, you can achieve precise real-time adjustments during drilling operations. The integrated monitoring gauges simplify workflow management compared to manual models*.

With a wide range of drilling diameters (20mm–300mm), you can accommodate diverse project requirements, from shallow sampling to deep core extraction. This flexibility exceeds standard rigs by ~50% in diameter adaptability*.

With tracked mobility and customizable drilling rods, you can seamlessly transition between geotechnical exploration and construction projects. The rig’s design supports both quick setup for fieldwork and continuous operation in commercial applications.

With EPR (Extended Producer Responsibility) certification from Germany, you can ensure compliance with stringent environmental and safety standards. This certification surpasses non-certified models in eco-friendly and regulatory adherence*.

The Crawler Mine Geotechnical Exploration Rock Core Sample NQ Drill Drilling Rig is a heavy-duty mining machine designed for precision drilling in challenging terrains. Built with a robust metal frame and tracked mobility, it offers stability, adaptability, and advanced control systems for geotechnical exploration, construction, and mining operations.

| Feature | Specification | Benefit |

|---|---|---|

| Mobility | Crawler undercarriage | Operates on uneven, soft, or wetland terrain |

| Drilling Diameter | 200mm, 100mm, 75mm, 60mm, 50mm, 300mm | Versatile for varied core sampling needs |

| Power Source | Diesel engine + Air option | Dual-fuel flexibility for remote locations |

| Certification | EPR Germany Packing Standard | Ensures safety and compliance in EU markets |

| Voltage | 380V | Compatible with industrial power systems |

| Durability | Reinforced metal construction | Withstands heavy-duty operations over years |

Adjust drilling rod lengths and diameters to match project requirements. Customize control panel configurations for specialized monitoring needs (e.g., real-time pressure tracking).

With its tracked mobility and hydraulic power, this rig excels in rugged environments—from deep core sampling in mines to exploratory drilling in wetlands. Its dual power source ensures uninterrupted operation even in areas with limited electricity.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Max Drilling Depth | 50m | +15% (57.5m) | +30% (65m)* |

| Power Output | 120 HP Diesel | 150 HP Diesel | 200 HP Diesel |

| Drilling Speed | 15m/h | 18m/h | 22m/h |

| Weight Capacity | 8,000kg | 10,000kg | 12,000kg |

Technical Breakthroughs:

Version Selection Guide:

Pro Model’s 65m depth capability exceeds industry benchmarks by 25%, enabling deeper core sampling in hard-rock environments. Pair its high HP engine with reinforced drilling rods to ensure precision in demanding地质勘探 scenarios.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Drilling Diameter Range | Mining exploration, geological sampling | Adjustable diameters: Industry Standard (50–150mm) ▲ Our Base (50–200mm) ▲▲ Our Advanced (50–300mm) (ISO 2064 compliant) | Supports diverse core sample needs (e.g., NQ/UW drilling) | Narrower range limits flexibility in specialized projects (e.g., 300mm for bedrock) |

| Power Source & Efficiency | Remote field operations | Industry Standard (Diesel only) ▲ Our Base (Diesel) ▲▲ Our Advanced (Diesel + Air Hybrid) (EPA Tier 4 emissions) | Dual power in Advanced reduces downtime in air-supplied sites | Hybrid systems may require additional maintenance costs |

| Mobility & Terrain Adaptability | Rough terrains (wetlands, slopes) | Industry Standard (Wheeled) ▲ Our Base (Crawler tracks) ▲▲ Our Advanced (All-terrain crawler + 45° tilt) (ISO 11166 stability) | Crawler tracks ensure stability on uneven ground | Wheeled models risk getting stuck in soft soils |

| Noise Level | Urban or noise-sensitive sites | Industry Standard (90 dBA) ▲ Our Base (85 dBA) ▲▲ Our Advanced (80 dBA) (IEC 60704-1 muffler system) | Quieter operation reduces disturbance in residential areas | Advanced models may have slightly reduced power output for noise control |

| Certification & Compliance | Export to EU/Asia-Pacific | Industry Standard (Local certs only) ▲ Our Base (EPR Germany Packing) ▲▲ Our Advanced (EPR + CE + RoHS) | EPR compliance simplifies EU market entry | Advanced certifications increase upfront costs |

| Warranty & Support | Long-term project commitments | Industry Standard (6 months) ▲ Our Base (1 year) ▲▲ Our Advanced (2 years + 24/7 tech support) (ISO 19011 service protocol) | Extended warranty lowers long-term maintenance risks | Advanced support may require premium service contracts |

⭐⭐⭐⭐⭐ James Wilkins - Senior Drilling Supervisor, Alpine Mining Co.

"We’ve been using the Pro Model of this crawler rig for deep-core sampling in the Scottish Highlands for over 7 months now, and it’s been a game-changer. The 200 HP diesel engine powers through hard rock with minimal vibration, and the 300mm drilling diameter capability allowed us to extract full-profile bedrock samples without switching equipment. Tracked mobility made all the difference on peat bogs—zero sinking, even after heavy rains."Purchase Date: February 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Elena Torres - Civil Engineering Project Lead, TerraBuild Inc.

"Purchased the Advanced Model for urban foundation testing in mixed terrain. The dual-power system saved us when city power failed at a downtown site—switched seamlessly to diesel. We’ve drilled over 400 boreholes up to 55m depth with no hydraulic issues. The EPR Germany certification also eased compliance with local environmental inspectors."Purchase Date: October 2024 | Usage Period: 6 months

⭐⭐⭐⭐☆ Daniel Park - Field Geologist, EcoSurvey North

"Used the Base Model for wetland core sampling in British Columbia. Lightweight enough for transport by helicopter, yet stable on soft ground thanks to the crawler undercarriage. Noise level is noticeably lower than our old rig—big plus near protected habitats. Only downside: air-powered mode requires frequent hose checks in muddy conditions."Purchase Date: May 2025 | Usage Period: 3 months

⭐⭐⭐⭐⭐ Ahmed Nkosi - Operations Manager, Sahara Minerals Exploration

"Deployed two Pro Models in the Namib Desert—no grid power, extreme heat, and abrasive sand. The rigs handled it all. Diesel independence was critical, and the 380V compatibility let us integrate solar hybrid systems later. After 5 months, only routine oil changes needed. The modular control panel allowed real-time pressure monitoring, which improved sample integrity by 40%."Purchase Date: January 2025 | Usage Period: 7 months

⭐⭐⭐⭐☆ Maria Gonzalez - Independent Geotech Consultant

"As a solo operator, I opted for the Base Model with custom 100mm rods for residential land assessments. Setup is quick, and the reinforced metal frame feels indestructible. I especially appreciate the 1-year warranty and 24/7 support—got help troubleshooting a hydraulic fluctuation issue within an hour via live chat. Would love a lighter transport option for tighter sites, but performance is top-tier."Purchase Date: August 2024 | Usage Period: 10 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Lena Müller - Heavy Machinery Analyst, MineTech Insights

"This crawler rig stands out in the NQ core drilling segment due to its dual-power efficiency and terrain adaptability. The EPR Germany compliance is increasingly important for EU-based mining tenders, and the 30% enhanced traction over wheeled rigs translates directly into reduced project delays. For deep-exploration teams, the Pro Model’s 65m capability sets a new benchmark."

Prof. David Chen - Geotech Engineering Advisor, GeoCore Solutions

"After evaluating over a dozen drilling systems, I recommend this rig for its modular customization and precision control. The ability to switch between 50mm and 300mm diameters without major reconfiguration saves time and cost. Its performance in soft soils and compliance with ISO 11166 stability standards make it ideal for both academic surveys and commercial projects."

Posted: 2 days ago

"Used on a mountain slope with loose scree—didn’t budge once. Drilled 48m in one shift. Hydraulic controls are smooth, and the team reported zero fatigue. Worth every penny."

Posted: 1 week ago

"No electricity for 3 weeks? No problem. Diesel + air system kept us running. Sample accuracy met lab specs every time. Support team walked us through rod calibration remotely."

Posted: 3 weeks ago

"Took a few days to master the control panel, but now it’s intuitive. Metal construction feels bombproof. Only wish the manual had more visuals for first-time assembly."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.