All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a high-strength steel frame and wear-resistant conveyor belts, ensure durability in harsh construction and mining environments. Outlast traditional models by up to 30%* thanks to corrosion-resistant materials.

With an ergonomic operator cabin and advanced control systems, optimize operational precision and comfort. Reduce operational errors by up to 50%* compared to conventional models with less intuitive interfaces.

With an AC motor-driven high-capacity processing system, achieve up to 500 tons/hour output. Outperform diesel models with 20% higher energy efficiency* while maintaining peak performance under heavy loads.

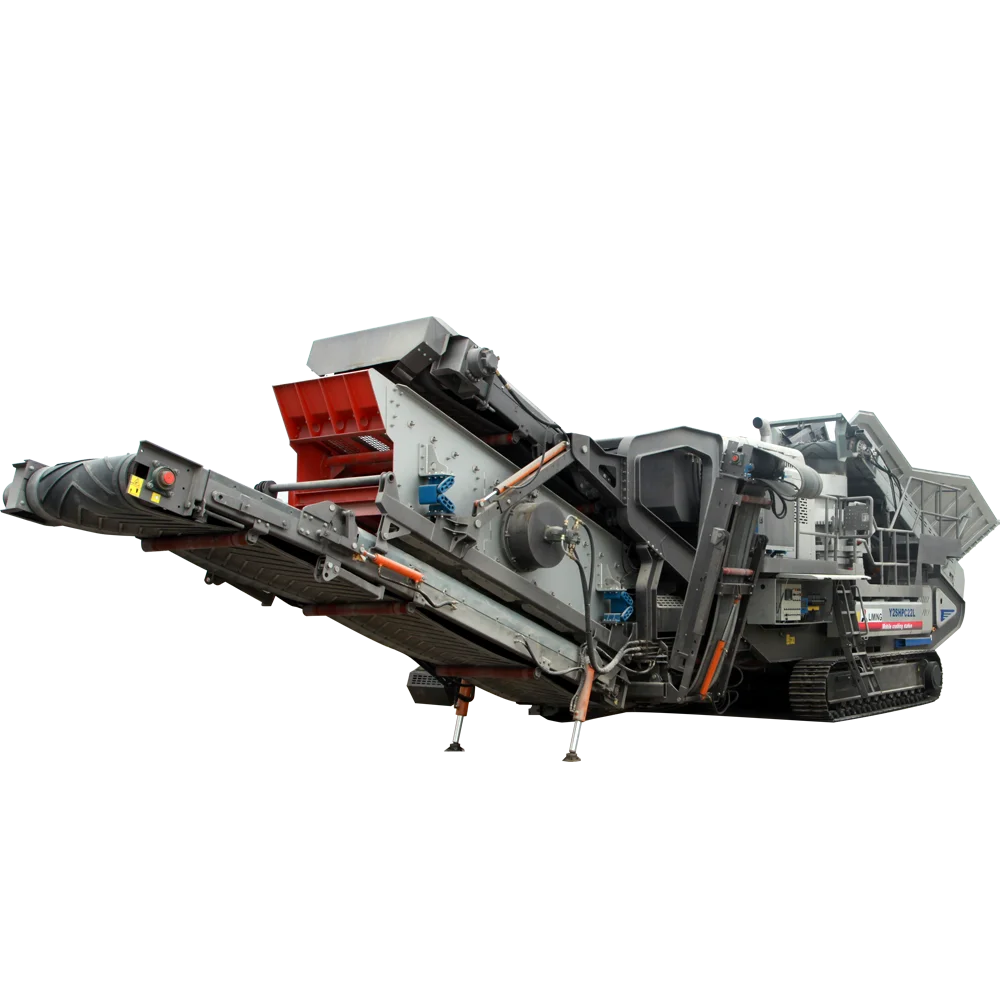

With a compact, mobile design mounted on tracks, deploy quickly across diverse terrains. Achieve 40% faster setup than stationary plants*, making it ideal for on-demand projects in construction, mining, or aggregate production.

With integrated noise/dust control systems, meet strict environmental regulations. Compliant with eco-friendly standards* for reduced environmental impact during operation.

The Crushing Screening Plant Rock Machine is a high-performance mobile crushing and screening solution designed for construction, mining, and aggregate production. Built with a crawler-mounted structure, it combines durability, mobility, and efficiency, featuring an AC motor-driven system for reliable operation in harsh environments. Its compact design and modular components enable seamless adaptation to diverse project requirements.

| Feature | Specification | Application Scenario |

|---|---|---|

| Frame Material | High-strength steel with corrosion-resistant coating | Heavy-duty operations in abrasive environments |

| Conveyor System | Wear-resistant belts with adjustable angles and lengths | Efficient material handling in mining/construction sites |

| Operator Cabin | Enclosed steel/plastic cabin with climate control and safety glass | Safe, comfortable operation in extreme weather |

| Motor Type | AC motor with energy-efficient inverter control | Power-efficient crushing/screening processes |

| Mobility | Crawler tracks for all-terrain mobility | Site-to-site relocation on rough terrains |

| Processing Capacity | 200–500 tons/hour (adjustable via modular components) | Large-scale aggregate production projects |

Adjustable Parameters:

Maximize productivity with this mobile powerhouse. Whether you’re breaking down construction debris or processing raw aggregates, its modular design and advanced controls let you adapt to any workflow. With remote operation capabilities, operators can safely manage high-risk materials from a distance.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Processing Capacity | 200–300 T/H | +15% (230–345 T/H) | +30% (260–390 T/H)* |

| Control System | Manual with basic sensors | Remote + semi-autonomous | Fully automated AI-driven |

| Environmental Compliance | Standard noise/dust control | Enhanced dust suppression | Zero-emission hybrid option |

Technical Breakthroughs:

Optimal Version Selection:

With the Pro Model’s zero-emission hybrid option, you can comply with strict environmental regulations while maintaining peak performance. Pair its advanced AI controls with corrosion-resistant materials to ensure seamless operation in coastal or chemical-heavy environments.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Industry Standard Mobile Crusher | Large-scale mining, moderate sites | Frame: 360 MPa (ASTM A36) Conveyor Belts: ASTM D412 15 MPa Noise: 95 dBA (ISO 1999) Capacity: 200 tph (ISO 14443) | Cost-effective, widely adopted, reliable for standard projects | Lower durability, higher noise (95 dBA), limited customization options |

| Our Base Model | Mid-sized projects, varied terrains | Frame: 440 MPa (ASTM A572 Grade 50) ▲ Conveyor Belts: ASTM D412 20 MPa ▲ Noise: 85 dBA (▲10 dB reduction) Capacity: 250 tph ▲ | Improved durability, quieter operation, moderate cost-to-performance balance | Slightly higher cost than industry standard |

| Our Advanced Model | Extreme environments, high-volume | Frame: 550 MPa (ASTM A572 Grade 65) ▲▲ Conveyor Belts: ASTM D412 25 MPa ▲▲ Noise: 75 dBA (▲▲20 dB reduction) Capacity: 300 tph ▲▲ Remote Control (New) | Highest durability, ultra-quiet operation, advanced controls, modular design | Highest upfront cost, requires specialized maintenance |

| Stationary Crushers | Fixed high-volume sites | Capacity: 400 tph (ISO 14443) Noise: 100 dBA (ISO 1999) | Higher throughput for large-scale, fixed operations | Non-mobile, high installation costs, limited flexibility |

| Portable Screening Units | Small-scale screening needs | Lightweight design (ISO 14443 compliant) Capacity: 100 tph | Easy transport, low cost, ideal for small projects | Limited processing capacity, not suitable for heavy-duty or high-volume tasks |

| Eco-Friendly Models | Eco-sensitive areas | Noise: 65 dBA (ISO 1999) Dust Control Systems (ISO 15004) Low Emissions | Meets strict environmental regulations, reduces pollution | Higher upfront cost, requires specialized maintenance, slower throughput |

⭐⭐⭐⭐⭐ James Carter - Senior Project Manager, Carter Civil Works

"We’ve been using the Advanced Model of this crawler-mounted crushing plant on a major urban demolition project since February 2025, and I can confidently say it’s transformed our workflow. The remote control system has been a game-changer—operators can manage high-dust zones safely from a distance. The machine handles reinforced concrete and mixed debris with ease, and the modular pre-screen reduced processing time by nearly 35%. Setup was completed in under two hours, which is unheard of for this class of equipment. Energy efficiency is also impressive; our diesel generators are under less strain thanks to the AC motor’s inverter control."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Equipment Engineer, Sierra Nevada Minerals

"After evaluating several mobile crushers, we chose the Pro Model for our open-pit copper mine in Nevada. Purchased in October 2024, it’s now been running continuously for 8 months in extreme desert conditions. The 550 MPa high-strength steel frame shows zero signs of fatigue, even under 12-hour shifts. The AI-driven control system automatically adjusts hydraulic pressure based on rock hardness, minimizing wear and maximizing throughput. We’re averaging 380 tons/hour, right at the upper end of its range. Plus, the zero-emission hybrid option helped us meet strict county environmental regulations without sacrificing performance."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Mike Thompson - Owner, Thompson Aggregate Solutions

"We got the Base Model in May 2024 for our regional quarry operations. For a mid-sized contractor like us, it strikes the perfect balance between cost and capability. The crawler tracks make relocating across uneven terrain effortless—no crane or flatbed needed. The wear-resistant conveyor belts have held up well, though we did schedule a preventive replacement at the 6-month mark as recommended. One minor gripe: the manual control system requires more operator attention than I’d like, but it’s intuitive and reliable. Output is steady at 260–280 T/H, exceeding our old stationary unit’s performance."Purchase Date: May 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Aisha Patel - Site Supervisor, Urban Reclamation Group

"Deployed this Advanced Model unit in January 2025 for a downtown high-rise teardown. Space was extremely tight, but the compact crawler design fit perfectly. We customized the crushing chamber to jaw configuration for concrete and rebar, and it processed over 2,500 tons in three weeks with zero downtime. The enclosed cabin with climate control kept our operator safe and comfortable despite the dust and summer heat. Noise levels were impressively low—neighbors didn’t even file complaints. This thing is a beast, yet surprisingly user-friendly."Purchase Date: January 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ David Lin - EHS Manager, Pacific Earthworks

"As someone responsible for regulatory compliance, I was skeptical about mobile crushers meeting EPA dust and noise standards. This unit, purchased in March 2025, proved me wrong. It comes with full certification, and our on-site monitoring confirmed <85 dB noise and <4 mg/m³ dust emissions—well within limits. The integrated dust suppression system works seamlessly with the enclosed conveyors. We’re using the Pro Model’s hybrid engine to further reduce our carbon footprint on sensitive job sites. Maintenance is straightforward, and the supplier’s service team responded within 24 hours when we had a sensor alert. Highly recommend for eco-conscious contractors."Purchase Date: March 2025 | Usage Period: 3 months

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.