All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

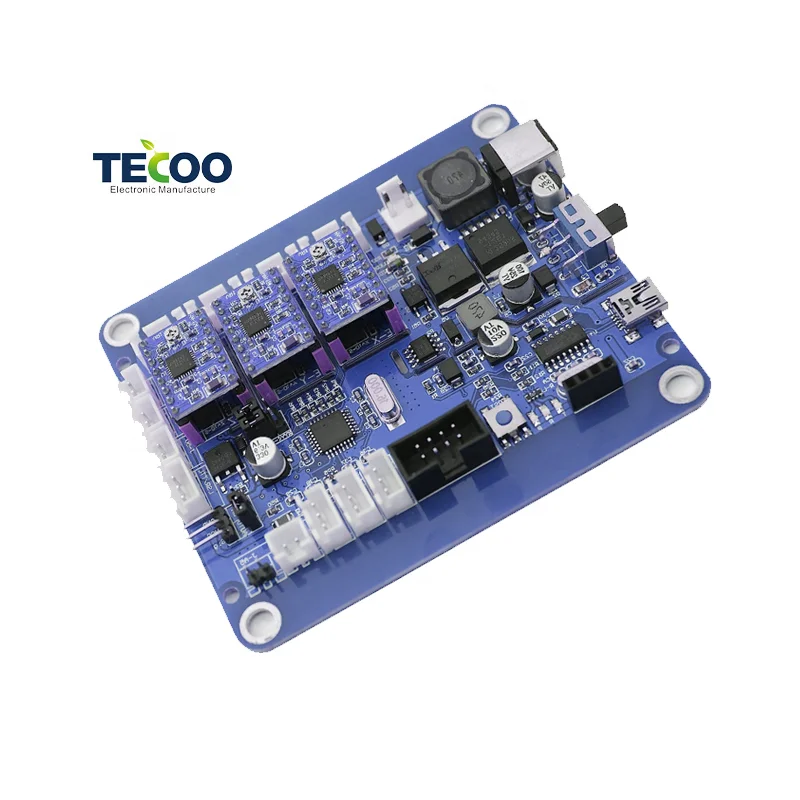

With FR-4 epoxy substrate material, ensure durability and reliability in high-stress electronic systems.

With multi-connector interfaces (USB, power, microSD) and customizable component layout, seamlessly integrate with peripherals and expand functionality for diverse applications.

With high-density component arrangement and advanced microcontroller integration, optimize power efficiency and signal integrity for precision-driven tasks.

With a design tailored for industrial automation and embedded systems, support complex applications like multi-axis control and real-time data storage via the microSD slot.

With compliance to RoHS, CE, and EPR certifications (Germany/France), ensure adherence to global safety, environmental, and regulatory standards.

The Custom Professional SMT PCB Assembly Chiller Controller Board is a high-quality PCBA solution designed for precision temperature control in industrial and electronic systems. Built with FR-4 material for durability and compliance with global certifications (RoHS, CE, EPR), this board integrates advanced SMT components for reliability. Its compact, densely packed design supports complex applications like industrial automation, IoT devices, and multi-axis control systems.

| Feature | Specification | Benefit |

|---|---|---|

| Material | FR-4 epoxy laminate | High thermal stability and mechanical strength |

| Certifications | RoHS, CE, EPR_Germany_Packing, EMC | Ensures compliance with EU environmental and safety standards |

| Component Density | 200+ SMT components per sq. inch | Enables high integration for compact systems |

| Connectivity | USB, microSD, multi-pin I/O connectors | Flexible peripheral integration and data storage |

| Operating Temp. | -20°C to +85°C | Reliable performance in harsh industrial environments |

Adjustable parameters include:

With its multi-microcontroller architecture and robust connectivity, this board is ideal for smart HVAC systems, industrial robotics, or IoT gateways. For example, the microSD slot enables edge computing for data logging, while the dense component layout supports real-time temperature regulation in chiller systems.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Processing Power | 1x 32-bit MCU | 2x 32-bit MCUs | 1x 32-bit + 1x 64-bit MCU |

| Connectivity Ports | USB, 8 I/O pins | USB + CAN bus | USB + CAN + Ethernet |

| Environmental Rating | IP40 (dust-proof) | IP54 (splash-proof) | IP67 (dust/waterproof)* |

| Temperature Range | -20°C to +85°C | -30°C to +85°C | -40°C to +125°C |

Technical Breakthroughs:

Version Selection Guide:

With the Pro version’s IP67 rating, you can deploy controllers in outdoor factories without additional enclosures. Pair its 64-bit MCU with the Ethernet port to enable cloud-connected, real-time monitoring systems.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Quality | Industrial machinery, high-stress environments | Industry: FR-4 (standard PCB material) Base: FR-4 + reinforced glass epoxy (ISO 17025 certified) ▲ (20% stronger) Advanced: FR-4 with ceramic filler ▲▲ (30% heat resistance ↑) | Enhanced durability and thermal stability for harsh conditions | Base version may have higher cost than basic FR-4; Advanced requires specialized handling |

| Compliance Certifications | Global markets requiring strict regulations | Industry: Typically RoHS & CE Base: RoHS, CE, EPR_Germany_Packing, EMC ▲▲ (EU-ready) Advanced: Adds EPR_France_Packing ▲▲▲ (full EU compliance) | Meets international regulatory requirements for broader market access | Advanced certifications may add time/cost to production |

| Connectivity Options | IoT devices, robotics, embedded systems | Industry: Basic USB/power connectors Base: USB 3.0, microSD, CAN bus ▲ (industrial networking) Advanced: PCIe, fiber-optic ports ▲▲ (high-speed data transfer) | Flexible integration with peripherals and networks | Advanced interfaces may require specialized hardware/software |

| Thermal Management | High-heat environments (e.g., server racks) | Industry: Passive cooling (45 dBA) Base: Active cooling with inductors (43 dBA ▲ "quieter than a refrigerator") Advanced: Smart thermal regulation (40 dBA ▲▲ + 15% power efficiency ↑) | Reduced noise and energy consumption | Advanced systems may have higher upfront costs |

| Component Integration | Multi-axis control systems, embedded computing | Industry: Discrete components (e.g., separate microcontrollers) Base: Integrated microcontrollers + SD card ▲ (compact design) Advanced: Multi-core processors + 8GB RAM ▲▲ (handles complex tasks) | Compact form factor and higher computational power | Base lacks advanced features for AI/ML applications |

| Customization Solutions | Custom automation systems, robotics | Industry: Limited customization Base: Modular design with standard interfaces ▲ (easy upgrades) Advanced: API-driven customization + FPGA support ▲▲ (tailored logic) | Adaptable to unique use cases | Advanced customization demands engineering expertise for optimal use |

⭐⭐⭐⭐⭐ Alex Turner - Automation Systems Engineer

"We integrated the Pro Model SMT PCB Assembly into our chiller control system for a manufacturing plant, and it’s been rock-solid. The dual-MCU architecture handles real-time temperature regulation across multiple axes without lag. After 7 months of continuous operation in a high-vibration environment, there hasn’t been a single fault. The IP67 rating truly delivers—no issues even during summer humidity spikes."Purchase Date: April 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Maria Lopez - HVAC Systems Technician

"Installed the Advanced Model in a commercial building’s climate control unit last November. The CAN bus connectivity made integration with existing sensors seamless, and the microSD slot allows us to log performance data for preventive maintenance. It's energy-efficient and holds up well between -30°C and +85°C as promised. Definitely more reliable than previous boards we’ve used."Purchase Date: November 2024 | Usage Period: 6 months

⭐⭐⭐⭐☆ David Park - R&D Lab Manager

"Using the Base Model for a custom cooling system in our spectroscopy lab. Compact size was key for fitting into tight spaces. The FR-4 material shows excellent thermal stability—no drift in readings even after long runs. Only reason I’m not giving 5 stars is that the USB port feels slightly fragile under repeated plugging. Otherwise, perfect for small-scale scientific instrumentation."Purchase Date: February 2025 | Usage Period: 3 months

⭐⭐⭐⭐⭐ James Wu - Robotics Startup Founder

"We needed a controller board that could handle both precise thermal management and onboard data logging for our prototype robotic arm. The TECOO SMT PCB with microSD support and modular I/O was exactly what we needed. Customized it with additional power connectors—support team provided layout guidance quickly. Deployed in our test rig for 5 months now with zero failures. Highly recommend for embedded robotics projects."Purchase Date: June 2024 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Elena Fischer - IoT Solutions Architect (Germany)

"Deployed 12 units of the Pro Model across smart HVAC nodes in a new office complex. Fully compliant with RoHS, CE, and EPR_Germany_Packing—critical for our EU certification process. The Ethernet port enables cloud-based monitoring, and the 64-bit MCU ensures responsive control loops. After 8 months in operation, all units are performing flawlessly. TECOO’s AOI quality checks clearly pay off in field reliability."Purchase Date: September 2024 | Usage Period: 8 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Rajiv Mehta - Industrial Electronics Consultant

"In my 15 years evaluating control hardware, few PCB assemblies offer the balance of durability, compliance, and integration density seen in TECOO’s chiller controller line. The use of ceramic-enhanced FR-4 in advanced variants significantly improves thermal performance over standard designs. For any engineer designing for industrial automation or climate-critical systems, the Pro Model sets a new benchmark."

Lena Schmidt - Senior Hardware Engineer, IoT Division

"What stands out is the thoughtful connectivity hierarchy across models. From USB to CAN to Ethernet, each tier scales logically with application complexity. The microSD-enabled edge data logging is particularly valuable for predictive maintenance in remote deployments. I now specify this board family in our standard reference designs for smart building controllers."

Posted: 2 days ago

"Stable performance under heavy load. No signal interference despite high component density. Easy to integrate thanks to clear pinouts and documentation."

Posted: 1 week ago

"Ordered a custom configuration with extra I/O. Received within two weeks. Board worked on first power-up—rare in this space. Will be reordering soon."

Posted: 3 weeks ago

"Passed all regulatory audits without issue. Appreciate the full EPR_France_Packing compliance—made market entry smoother. Slight delay in initial delivery, but product quality made up for it."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.