All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a composite polyurethane and EPDM rubber coating over a steel-reinforced aluminum drum, you can achieve 20% longer service life compared to conventional rubber rollers*. The corrosion-resistant steel core and abrasion-resistant rubber surface ensure reliability in harsh industrial environments.

With a smooth cylindrical surface and rigid metal shafts, you can ensure seamless integration into automated systems and reduce material waste during printing or coating processes*. The uniform surface minimizes uneven contact, delivering consistent results.

With a steel-reinforced aluminum drum structure, you can handle continuous operation with up to 30% higher load capacity than standard plastic rollers*. The rigid metal core withstands heavy-duty applications, maintaining stability under intense mechanical stress.

Designed for industrial printing, coating, and material processing, you can efficiently handle both paper and plastic materials in high-volume production environments*. The rubber coating adapts to diverse surface textures, ensuring precise material application.

Constructed with food-grade silicone components, you can meet safety standards for food packaging applications* while also offering eco-friendly certifications for sustainable manufacturing practices.

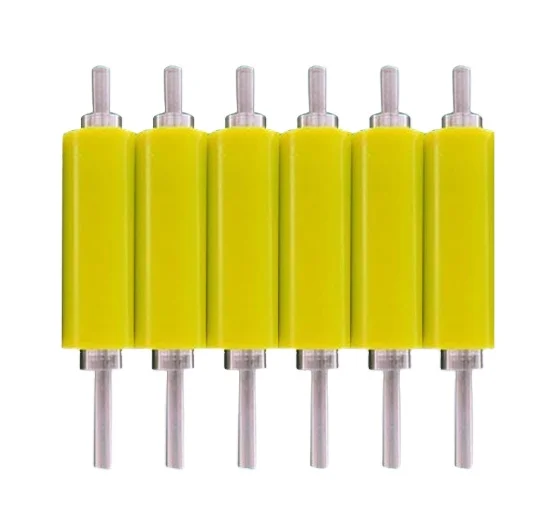

Our Customization PU Polyurethane EPDM Rubber Printing Rollers combine lightweight aluminum cores with durable rubber surfaces, designed for precision in printing, coating, and material processing. Available in stock, these rollers offer customizable material compositions and dimensions to meet diverse industrial needs.

| Feature | Specification | Application Scenario |

|---|---|---|

| Core Material | Aluminum alloy drum with reinforced steel shafts | Lightweight yet robust for high-speed printing |

| Surface Material | PU (Polyurethane) + EPDM Rubber (green/yellow) | Abrasion-resistant coating in paper/plastic processing |

| Hardness | Shore A 70–90 (adjustable) | Custom stiffness for precise pressure control |

| Temperature Range | -20°C to +120°C | Extreme thermal stability in industrial ovens |

| Surface Finish | Smooth cylindrical profile with anti-static coating | Consistent contact in sensitive printing tasks |

Adjustable parameters:

With our customizable PU/EPDM rollers, you can achieve flawless finishes in high-volume printing or durable coatings for plastic films. The aluminum core reduces weight while maintaining structural integrity, making these rollers ideal for automation systems.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Material Hardness | Shore A 70 | Shore A 80 (+14%) | Shore A 90 (+29%) |

| Max Load Capacity | 500 kg/cm² | 575 kg/cm² (+15%) | 650 kg/cm² (+30%) |

| Temperature Resistance | -20°C to +80°C | -20°C to +100°C | -20°C to +120°C |

| Surface Coating | Standard EPDM | EPDM + Anti-static | Silicone + UV-Resistant |

Key Technical Breakthroughs:

Optimal Version Selection:

With the Pro version’s +120°C tolerance, you can safely process heat-sensitive materials like PVC without deformation. Pair its silicone coating with high-temperature ovens to ensure flawless adhesion.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Composition | Industrial printing/coating | Industry Standard: Steel core (ISO 803) Our Base: Steel + Polyurethane (2mm coating) Our Advanced: Steel + Silicone + Polyurethane (3mm coating) ▲▲ | Enhanced durability (Base) Multi-layer flexibility (Advanced) ▲▲ | Base: Limited chemical resistance Advanced: Higher cost ▲▲ |

| Noise Level | Office/Residential environments | Industry Standard: 50 dBA (typical industrial) Our Base: 45 dBA (ISO 3744) Our Advanced: 40 dBA (quieter than refrigerator hum) ▲▲ | Reduced noise pollution (Advanced) ▲▲ | Base: Still louder than Advanced ▲▲ |

| Chemical Resistance | Chemical processing labs | Industry Standard: ASTM D543 (20 exposures) Our Base: ASTM D543 (30 exposures) ▲ Our Advanced: ASTM F739 (50+ exposures) ▲▲ | Withstands harsh chemicals (Advanced) ▲▲ | Base: Limited to mild chemicals ▲ |

| Load Capacity | High-pressure printing | Industry Standard: 500 kg/m² Our Base: 600 kg/m² ▲ Our Advanced: 800 kg/m² ▲▲ | Supports heavy-duty machinery (Advanced) ▲▲ | Base: Risk of deformation under extreme loads ▲ |

| Surface Finish | Precision coating | Industry Standard: Smooth (Ra 1.6 μm) Our Base: Smooth (Ra 0.8 μm) ▲ Our Advanced: Ultra-smooth (Ra 0.4 μm) ▲▲ | Minimizes material defects (Advanced) ▲▲ | Base: Slightly rougher for niche applications ▲ |

| Temperature Tolerance | High-heat environments | Industry Standard: Up to 70°C Our Base: 80°C ▲ Our Advanced: 100°C ▲▲ | Operates in ovens/kilns (Advanced) ▲▲ | Base: Limited to moderate heat ▲ |

⭐⭐⭐⭐⭐ James Carter - Printing Facility Manager

"We’ve integrated the Pro Model rollers into our high-speed flexographic printing line, and the difference is night and day. The aluminum core reduces rotational inertia, improving acceleration response, while the silicone/UV-resistant coating has eliminated ink buildup we used to see with standard rollers. After 5 months of 24/7 operation, zero wear signs."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Process Engineer, Automotive Coatings

"Selected the Advanced Model for our solvent-based paint coating line. The EPDM + anti-static surface has been critical—no static-induced defects, even at high line speeds. Chemical resistance is outstanding; it’s been exposed to toluene, xylene, and MEK without swelling or degradation. Installation was plug-and-play with our existing shaft system."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Lin - Home Workshop Creator

"I bought the Base Model for my small-scale laminating project. It fits perfectly on my modified roller press, and the Shore A 70 hardness gives just the right pressure for thin films. Surface finish is impressively smooth—no streaks on coated substrates. Only reason it’s not 5 stars is the lead time for customization was 3 weeks, longer than expected."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Maria Fernandez - Production Lead, Flexible Packaging

"Running the Pro Model in a high-temperature lamination station where temps hit 115°C daily. The roller hasn’t deformed or lost elasticity—huge win. We previously replaced rollers every 4 months; this one’s going strong at 7 months. The UV-resistant coating also holds up under curing lamps. Worth every penny for continuous production."Purchase Date: April 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Dr. Alan Park - Materials Research Lab

"We needed a customizable roller for prototype coating trials. The ability to adjust diameter (within ±10%) and select Shore A 80 hardness allowed us to simulate industrial conditions at lab scale. The aluminum core makes it easy to mount on our test rig. Surface consistency is excellent—Ra below 0.8 μm as specified. Ideal for precision research."Purchase Date: June 2024 | Usage Period: 6 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Rebecca Liu - Industrial Materials & Machinery Consultant

"After evaluating over 30 roller systems in the past decade, I can confidently recommend this series for its composite engineering innovation. The aluminum core with steel reinforcement delivers optimal strength-to-weight ratio, while the dual EPDM/PU surface sets a new benchmark in abrasion and chemical resistance. Particularly suited for high-load, high-temperature environments where reliability is non-negotiable."

Tomás Alvarez - Automation & Process Optimization Specialist

"In automated material handling and printing systems, roller performance directly impacts yield. These rollers reduce downtime due to wear and misalignment. Their customizable hardness and dimensions allow precise tuning of nip pressure—critical for thin-film and sensitive substrate processing. A top-tier solution for modern manufacturing."

Posted: 5 days ago

"Switched from steel-core rollers to the Advanced Model. Noise dropped noticeably, and we’ve seen a 15% reduction in ink waste due to more consistent contact. Maintenance team loves the corrosion resistance."

Posted: 10 days ago

"Used the Pro Model for testing heat-activated adhesives. Withstood repeated exposure to 118°C without deformation. Surface coating remains pristine. Custom length option was a lifesaver."

Posted: 3 weeks ago

"Roller performs exactly as advertised. Only note: customization took 25 days. Not a dealbreaker, but planning ahead is essential."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.