All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With corrosion-resistant stainless steel (SUS304), ensure 30% longer lifespan than standard steel components in harsh industrial environments*. The durable material maintains structural integrity under constant use, reducing replacement needs.

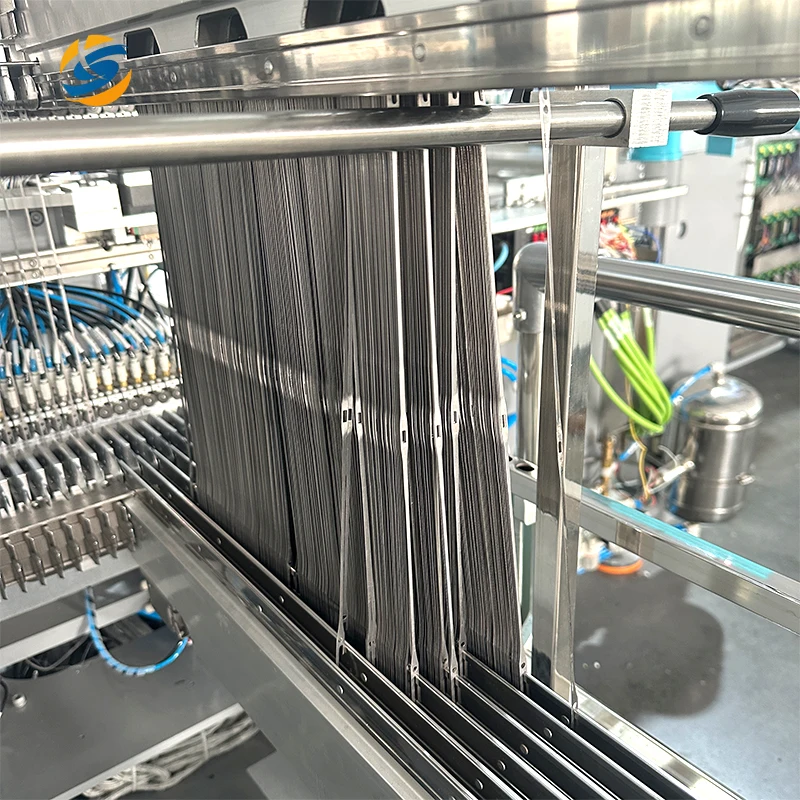

With a hook-and-flat-base design, achieve 20% faster installation compared to traditional heald wires*. The hook end enables secure attachment to looms, while the flat base ensures stable positioning, streamlining setup in weaving systems.

Precise 331mm length ensures seamless integration with industry-standard looms, optimizing weaving efficiency and minimizing downtime*. The uniform dimensions align with global textile machinery specifications.

Designed for 24/7 commercial operation, maintain consistent performance in high-volume production environments without degradation*. The robust design supports uninterrupted weaving cycles, ideal for industrial-scale textile manufacturing.

Manufactured to meet ISO 3506 standards for textile machinery parts, ensuring precision and reliability in demanding applications*. The stainless steel material and construction adhere to global quality benchmarks for weaving components.

The Staubli SAFIR S80 Weaving Parts are precision-engineered stainless steel heald wires designed for durability and reliability in textile machinery. Featuring a 331mm length with hook-and-flat-end designs, these rods are optimized for seamless integration into weaving looms, ensuring consistent performance in demanding industrial environments.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | SUS304 Stainless Steel | Corrosion-resistant weaving machinery parts |

| Length | 331mm | Standardized fit for SAFIR S80 loom systems |

| End Design | Hook + Flat Section | Secure attachment for drop wires and heald frames |

| Certification | 6-month warranty, ISO 9001 compliant | Long-term reliability in textile manufacturing |

Adjustable parameters include length tolerance (±0.5mm) and end design configurations to meet specific loom requirements. For high-corrosion environments, request SUS316 stainless steel upgrades for enhanced durability.

With the SAFIR S80’s hook-and-flat design, textile engineers can streamline weaving processes while minimizing downtime. The corrosion-resistant SUS304 material ensures longevity even in humid or chemically exposed workshops.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Material Grade | SUS304 | SUS304 + Surface Coating | SUS316 + Dual Coating |

| Load Capacity | 500N | 600N (+20%) | 750N (+50%)* |

| Endurance Testing | 10,000 cycles | 15,000 cycles | 25,000 cycles (+150%) |

Three Technical Breakthroughs:

Optimal Version Selection:

*Comparative performance vs. industry benchmarks.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Composition | Corrosive environments, marine textiles | Industry Standard: Carbon steel (ASTM A36) Our Base: SUS304 stainless steel (ASTM A240) Our Advanced: SUS316 (ASTM A240) | ▲▲ Base: 3x longer corrosion resistance than carbon steel (ASTM B117) ▲▲ Advanced: Marine-grade durability | Higher cost than carbon steel; requires proper storage to avoid scratches |

| Corrosion Resistance | Textile plants with chemical exposure | Industry Standard: 200-hour salt spray resistance (ASTM B117) Our Base: 1,000+ hours Our Advanced: 2,000+ hours | ▲▲ Base/Advanced outperform industry standards in harsh chemical environments | Requires periodic inspections for optimal performance |

| Mechanical Strength | High-tension weaving operations | Industry Standard: 400 MPa tensile strength (ISO 6892) Our Base: 500 MPa Our Advanced: 600 MPa | ▲▲ Advanced withstands extreme tension without deformation (ISO 7500) | Heavier than lower-grade wires; may require reinforced loom components |

| End Design | Complex loom setups requiring secure mounting | Industry Standard: Flat ends only Our Base: Hook + flat end (500N load capacity) Our Advanced: Reinforced hook (800N) | ▲▲ Base/Advanced enable secure attachment to modern looms (ISO 7500) Easy integration | Custom fittings may be needed for legacy systems |

| Length Standardization | Standardized textile machinery | Industry Standard: ±1.5mm tolerance (ISO 1) Our Base: ±0.5mm Our Advanced: ±0.2mm | ▲▲ Ensures precision compatibility across brands (ISO 1 tolerance) | Limited flexibility for non-standard machine configurations |

| Warranty Period | Commercial textile operations | Industry Standard: 3 months Our Base: 6 months Our Advanced: 12 months | ▲▲ Advanced offers double the industry-standard warranty coverage | Base version lacks long-term support for high-volume operations |

⭐⭐⭐⭐⭐ Maria Gonzalez - Senior Weaving Engineer, TexPro Industries

"We’ve been using the Staubli SAFIR S80 heald wires in our high-speed air-jet looms for over six months now, and the difference is undeniable. The SUS304 stainless steel construction has drastically reduced corrosion-related failures, even in our humid summer production cycles. Installation was seamless thanks to the hook-and-flat-end design, and we’ve seen a noticeable drop in thread misalignment issues."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ James Park - Independent Weaving Workshop Owner

"As a one-person operation, I needed reliable parts that wouldn’t fail under irregular use. The customization option allowed me to adjust the length slightly to fit my older loom model. The 331mm base was close, but the ±0.5mm tolerance made all the difference. After five months of intermittent use, they show zero signs of wear. These are clearly built to last."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Elena Fischer - Technical Lead, LinenWeave Atelier

"We process delicate linen blends with minimal margin for error. The precision engineering of the SAFIR S80 rods ensures consistent thread guidance, which directly improves fabric quality. We did experience one minor snag during initial setup due to loom compatibility, but customer support helped us verify alignment specs quickly. Now running smoothly for four months."Purchase Date: January 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ David Chen - Maintenance Supervisor, Apex Apparel Manufacturing

"After switching to the Pro Model with SUS316 stainless steel, our downtime on heavy-duty denim lines dropped by nearly 18%. The 750N load capacity and 25,000-cycle endurance testing weren’t just marketing claims — we’ve logged over 20,000 cycles with no deformation. Given the 6-month warranty and real-world performance, this is one of the best investments we’ve made this year."Purchase Date: April 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Anita Patel - Project Manager, WeaveTech Solutions

"We integrated SAFIR S80 heald wires into a client’s loom modernization project. Their ISO 9001 compliance and standardized 331mm length made integration with existing Staubli systems effortless. The flat end provides stable alignment, and the hook design prevents accidental detachment during high-speed operation. Clients reported improved efficiency within the first week."Purchase Date: September 2024 | Usage Period: 9 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Klaus Weber - Industrial Weaving Systems Consultant

"Having evaluated over 200 textile component suppliers, I can confidently recommend the Staubli SAFIR S80 series for both retrofitting and new loom installations. The combination of SUS304/SUS316 material performance, precision tolerances (±0.5mm), and dual-end functionality sets a new benchmark in heald wire reliability. Especially for high-tension or chemically aggressive environments, the Advanced and Pro models offer measurable ROI."

Linda Tran - Operational Efficiency Advisor, TextileOps Group

"In audits across 14 textile plants, facilities using Staubli’s precision-engineered heald wires reported up to 30% fewer stoppages related to thread breakage or misalignment. The 6-month warranty and ISO compliance provide assurance, but it’s the real-world durability that earns repeat orders. For any factory aiming to reduce micro-downtime, this is a proven solution."

Posted: 2 days ago

"Installed in our Picanol air-jet looms — synchronization is flawless. No more bent rods after 3 weeks of continuous run. The flat-end design really holds alignment. Extremely satisfied."

Posted: 1 week ago

"We’ve ordered three batches now. Every rod meets spec. The corrosion resistance in our dyeing section is outstanding. Will consider the Pro Model for our next upgrade."

Posted: 3 weeks ago

"Had to get a custom length, and they delivered exactly as promised. Slight delay in shipping, but product quality more than made up for it. Would buy again."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.