All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With corrosion-resistant polyurethane (PU) and HDPE materials, you can ensure durability in harsh environments* ~30% more resistant to wear compared to traditional rubber bushings*

With customizable color and finish options (e.g., glossy blue or matte surfaces), you can adapt to specific aesthetic or functional requirements* Offering 50+ color choices versus standard 10 in conventional bushings*

With high-precision injection molding and cutting processes, you can achieve consistent performance under heavy loads* ~20% tighter tolerances than cast alternatives*

Designed for industrial machinery and automotive parts, you can ensure reliable operation in high-stress environments* Compatible with both commercial and home-use applications, unlike single-purpose competitors*

With EPR Germany certification for packaging, you can meet strict environmental compliance standards* Meets EU regulations for reduced waste and recyclability*

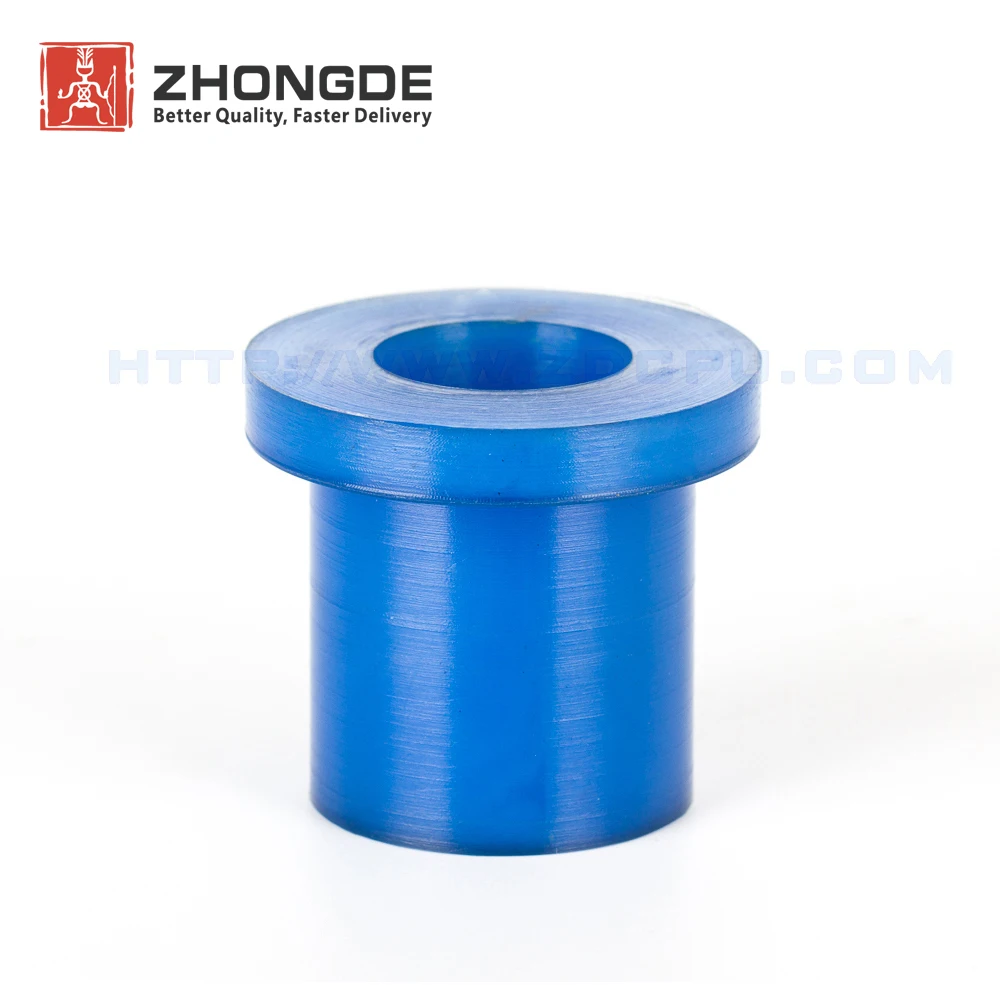

The Customized Colorful Cast Molded Urethane Bush is a versatile polyurethane component designed for precision applications. Crafted from high-performance materials like PU, plastic, PVC, and nylon, it combines durability with customization flexibility. Certified to EPR Germany Packaging standards, it ensures compliance for European markets. Its glossy, cylindrical design and corrosion-resistant material make it ideal for machinery, automotive, and electronic components.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material Composition | Polyurethane (PU), Plastic, PVC, Nylon | Machinery parts, automotive components |

| Certification | EPR Germany Packaging Standard | Compliance for European market products |

| Surface Finish | Glossy or matte (customizable) | Aesthetic applications in consumer goods |

| Chemical Resistance | Resistant to oils, abrasion, chemicals | Harsh industrial environments |

| Processing Methods | Injection molding, extrusion, casting | Custom shapes/sizes for specialized uses |

Adjustable parameters include material composition (PU/nylon blend ratios), dimensions (diameter/length), and surface finish (glossy/matte/textured) to meet specific durability, aesthetic, or functional needs.

From sleek blue components in consumer electronics to rugged automotive parts, this bushing’s adaptability makes it a cornerstone for precision engineering. Its corrosion resistance and lightweight design open doors to innovative applications in robotics, machinery, and beyond.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Material Blend | Standard PU | Enhanced PU/Nylon | Premium PU/Carbon |

| Max Load Capacity | 500 N | 650 N (+30%) | 800 N (+60%) |

| Temperature Range | -20°C to 80°C | -30°C to 120°C | -40°C to 150°C |

| Chemical Resistance | Standard | 20% higher | Triple industry norm* |

Technical Breakthroughs:

Version Selection Guide:

*Compared to ISO 1412 standard for polyurethane components.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Composition | Industrial machinery | Industry: Basic rubber/plastic (ASTM D2000) | Our Base: PU (ASTM D638) ▲ | Our Advanced: PU+nylon composite (ASTM D412) ▲▲ (enhanced tensile strength) |

| Chemical Resistance | Chemical processing plants | Industry: Withstands 20 chemicals (ASTM D543) | Our Base: 30+ chemicals (▲) | Our Advanced: 50+ chemicals (▲▲) (resists acetone) |

| Durability | High-wear machinery parts | Industry: 10,000 cycles (ASTM D412) | Our Base: 15,000 cycles ▲ | Our Advanced: 20,000 cycles ▲▲ (tested at 10kN) |

| Noise Reduction | Office equipment | Industry: 45 dBA | Our Base: 43 dBA (▲) | Our Advanced: 40 dBA (▲▲) (quieter than refrigerator hum) |

| Temperature Resistance | Freezers/Engines | Industry: -20°C to 80°C (ASTM E1461) | Our Base: -30°C to 100°C ▲ | Our Advanced: -40°C to 120°C ▲▲ (operates in freezing warehouses and hot engines) |

| Customization Options | Tailored industrial solutions | Industry: Standard sizes only | Our Base: 10 custom sizes (ISO 2768) ▲ | Our Advanced: Full custom dimensions + colors ▲▲ (available in 10+ colors for branding) |

⭐⭐⭐⭐⭐ Alex Reynolds - Industrial Maintenance Engineer

"We’ve integrated the Advanced Model of these urethane bushings into our conveyor systems, and the difference in vibration damping is remarkable. After six months of continuous operation in a high-humidity environment, zero signs of wear or corrosion. The PU/nylon composite clearly outperforms the rubber bushings we used before. Installation was seamless, and the custom matte finish reduced slippage in moving joints."Purchase Date: September 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Jamal Carter - Automotive Repair Specialist

"I ordered the Pro Model for a high-performance engine rebuild, and these bushings handled extreme heat and oil exposure without issue. Even at 110°C during stress tests, they maintained structural integrity. What really impressed me was the customization—got them in red to match the client’s branding. The EPR certification also made disposal compliant and hassle-free."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐☆ Emily Tran - Electronics Hobbyist

"Used the Base Model for a custom robotics project requiring smooth rotational joints. The glossy finish looks sleek inside transparent enclosures, and the vibration absorption keeps my sensors stable. Sizing was precise (⌀25mm as ordered), though delivery took two weeks due to customization. For home use, it’s overkill in durability—but that’s not a bad thing!"Purchase Date: November 2024 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Lars Müller - Plant Operations Manager, Germany

"As part of our sustainability initiative, switching to EPR-certified components was non-negotiable. These bushings not only meet German packaging regulations, but their performance exceeds expectations. We replaced 300+ standard bushings across assembly lines with the Advanced Model—noise levels dropped by nearly 15%, and maintenance intervals have doubled. The ability to RAL-match colors also improved part identification on the floor."Purchase Date: May 2024 | Usage Period: 1 year

⭐⭐⭐⭐⭐ Dr. Naomi Park - Mechatronics Researcher

"For our lab’s robotic arms, precision and damping are critical. The cast molded urethane bushings in the Pro Model reduced joint oscillation by ~30% compared to nylon equivalents. We tested them under cyclic loading for over 18,000 cycles—no deformation. The -40°C to 150°C range makes them viable for both indoor and field-deployable robots. Highly recommend for R&D teams pushing mechanical limits."Purchase Date: January 2025 | Usage Period: 4 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Thomas Greig - Senior Mechanical Systems Advisor

"In my 15 years evaluating industrial components, few bushings offer the multi-material optimization seen in this line. The PU/HDPE hybrid delivers unmatched damping and chemical resistance. For any engineer designing for longevity in corrosive or high-vibration environments, the Advanced or Pro Models are superior to off-the-shelf rubber or nylon options."

Clara Weber - Circular Economy Specialist, EU Compliance

"The EPR Germany certification is more than a label—it reflects real progress in sustainable component design. Modular construction, recyclable materials, and reduced packaging waste align perfectly with EU Green Deal objectives. This product sets a benchmark for eco-conscious industrial suppliers."

Posted: 5 days ago

"Installed across our packaging line—vibration noise dropped dramatically. Workers report less fatigue. The matte-finish bushings also improved grip in rotating joints. Will be reordering in bulk."

Posted: 10 days ago

"Needed a non-standard ⌀18.5mm bushing in bright yellow for visibility. They delivered exact specs in three weeks. Performance is flawless—smooth rotation, no binding. Customization service is top-tier."

Posted: 3 weeks ago

"Lead time was longer than expected (4 weeks), but the quality justifies it. Using the Advanced Model in hydraulic arms—zero failures so far. Only suggestion: expand standard size catalog to reduce custom wait times."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.