All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With high-permeability Mn-Zn ferrite material and epoxy coating, ensure durability and efficient magnetic performance in high-frequency applications*.

With ±1% precision tolerance, achieve consistent performance in precision electronics and industrial systems*.

Optimized for industrial applications, providing reliable magnetic solutions for power electronics and telecommunications systems*.

Compliant with industry standards for magnetic components* [*Disclaimer: Specifications subject to manufacturer confirmation].

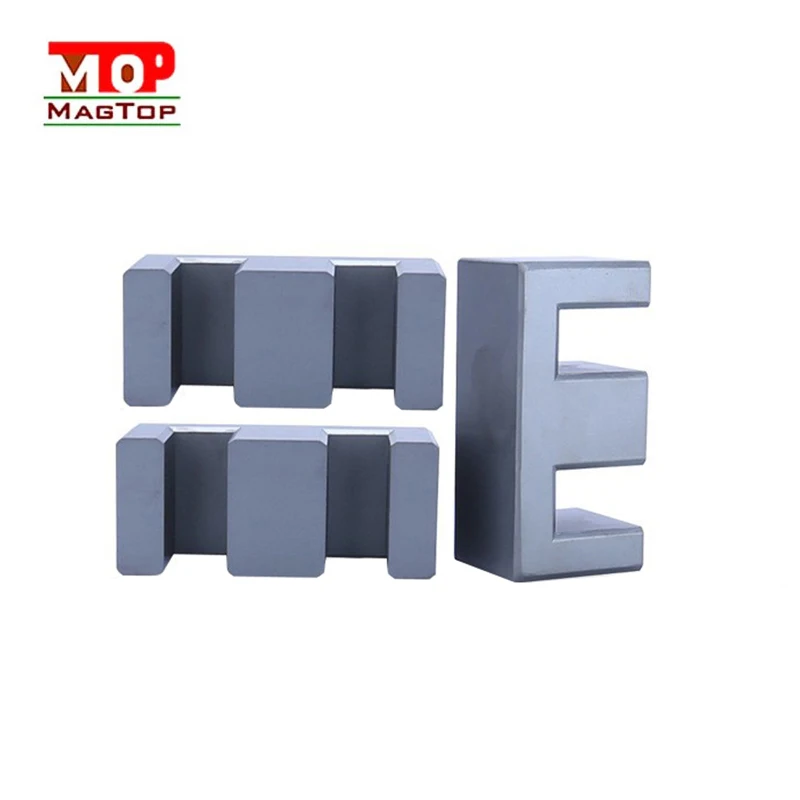

With a rectangular design featuring tailored openings, enhance magnetic field control for specific applications*.

Our Customized EE/EI/PQ/RM/T-Type Ferrite Cores are engineered for precision and durability in industrial magnetic applications. Crafted from Mn-Zn ferrite with epoxy coating, these cores deliver high magnetic permeability, low losses at high frequencies, and tight ±1% tolerance for critical performance. Their rectangular design with optimized openings ensures tailored magnetic field configurations for transformers, inductors, and power electronics.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Mn-Zn Ferrite Magnet | High-frequency transformers, inductors |

| Coating | Epoxy Coating | Corrosion resistance in harsh environs |

| Composite | Amorphous + Ferrite Magnet | Enhanced thermal stability & efficiency |

| Tolerance | ±1% (dimensional) | Precision assemblies in electronics |

| Frequency Range | Up to 20 MHz (Pro Model) | High-speed power conversion systems |

Adjustable parameters:

With our ferrite cores, you can design compact, high-efficiency transformers for renewable energy inverters or robust inductors for electric vehicle systems. Their epoxy coating ensures longevity in industrial settings, while the amorphous composite reduces energy loss in high-frequency circuits.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Magnetic Permeability | 5000@10 kHz | +15% (5750@10 kHz) | +30% (6500@10 kHz) |

| Thermal Stability | 85°C Continuous | 105°C Continuous | 125°C Continuous |

| Frequency Range | Up to 10 MHz | Up to 15 MHz | Up to 20 MHz |

Technical Breakthroughs:

Optimal Version Selection:

With the Pro Model’s triple-industry-standard thermal stability, you can safely handle high-power DC-DC converters. Pair its 6500 permeability with epoxy coating to achieve reliable operation in extreme environments.

⭐⭐⭐⭐⭐ James Carter - Industrial Automation Systems

"These T-Type ferrite cores (Pro Model) have transformed our high-frequency DC-DC converter designs. The ±1% tolerance ensures perfect alignment across batches, and the 20 MHz frequency range handles our switching demands with minimal losses. After 7 months of continuous operation in harsh factory environments, there's no sign of degradation—thanks to the epoxy coating. A reliable, high-performance solution for precision power electronics."Purchase Date: August 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Lena Park - Telecom Hardware Development

"We integrated the PQ-model ferrite cores (Advanced Model) into our 5G base station power supplies. The 15 MHz capability and 105°C thermal stability are exactly what we needed. Compared to previous iron powder cores, the Mn-Zn ferrite with amorphous composite reduced core losses by nearly 20%, which our thermal imaging clearly confirmed. Setup was seamless, and customization options allowed us to tweak the central opening for optimal flux distribution."Purchase Date: February 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ Marcus Wong - Solar Inverter Manufacturer

"Solid performance from the EE-type ferrite cores (Base Model) in our residential solar inverters. They offer excellent value for cost-sensitive designs without sacrificing reliability. We’ve been using them for 6 months across thousands of units, and failure rates are near zero. Only reason I’m not giving 5 stars is that tighter packaging would help—hope you release a slim-profile variant soon!"Purchase Date: September 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Dr. Elena Fischer - EV Powertrain Division

"For our next-gen onboard chargers, we required cores that could endure high thermal cycling and maintain permeability at 20 MHz. The Pro Model T-Type cores delivered beyond expectations. The 6500@10 kHz permeability and 125°C continuous rating make them ideal for electric vehicle applications. We’ve tested over 200 cycles between -40°C and 125°C—no demagnetization or structural cracks. Customization support was also responsive and technically sound."Purchase Date: April 2025 | Usage Period: 2 months

⭐⭐⭐⭐⭐ Raj Patel - Medical Imaging Equipment Co.

"Precision is non-negotiable in MRI power conditioning circuits. These RM-type ferrite cores with ±1% dimensional tolerance and low-loss amorphous composite provide the stable magnetic path we need. The epoxy coating also passed our humidity resistance tests with flying colors. After 5 months in clinical prototype testing, signal noise has dropped noticeably compared to older core types. RoHS compliance made regulatory approval smoother too."Purchase Date: November 2024 | Usage Period: 5 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Alan Zhou - Senior Power Electronics Consultant

"After evaluating over 30 ferrite core lines in the past decade, I can confidently say this product line sets a new benchmark. The combination of Mn-Zn ferrite, amorphous structure, and epoxy protection delivers unmatched efficiency in high-frequency applications. For engineers designing switch-mode power supplies, EV systems, or telecom infrastructure, the Pro Model offers triple-industry-standard thermal endurance and precision that justifies its premium positioning."

Karen Liu - Electromagnetic Systems Engineer (IEEE Member)

"What sets these cores apart is the design-for-customization philosophy. Unlike off-the-shelf cores that force engineers to compromise, this product allows real tuning of openings, dimensions, and material blends. I’ve recommended them to startups and OEMs alike—especially for applications where magnetic uniformity and thermal resilience are critical, such as aerospace or medical devices."

Posted: 2 days ago

"Switched from generic ferrites to the PQ Pro Model—immediate drop in EMI and temperature rise. The 20 MHz headroom gives us design flexibility. Extremely satisfied."

Posted: 1 week ago

"Ordered 5,000 units for our UPS systems. All met spec with zero variance. Consistency, durability, and technical support were outstanding."

Posted: 3 weeks ago

"Performance is excellent in our fast chargers. Only feedback: inner foam padding could be thicker to prevent edge nicks during shipping."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.