All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With silicon nitride ceramic, achieve 30% higher wear resistance than steel balls*.

With heat resistance up to 1400°C, you can operate in extreme environments without degradation.

Designed for furnace fixtures and electrical insulators, you can ensure reliability in high-stress industrial operations.

Complies with EPR France/Germany and RoHS standards, ensuring environmental and safety compliance.

With precision-engineered sizes from 0.8–25mm, you can adapt to diverse industrial applications.

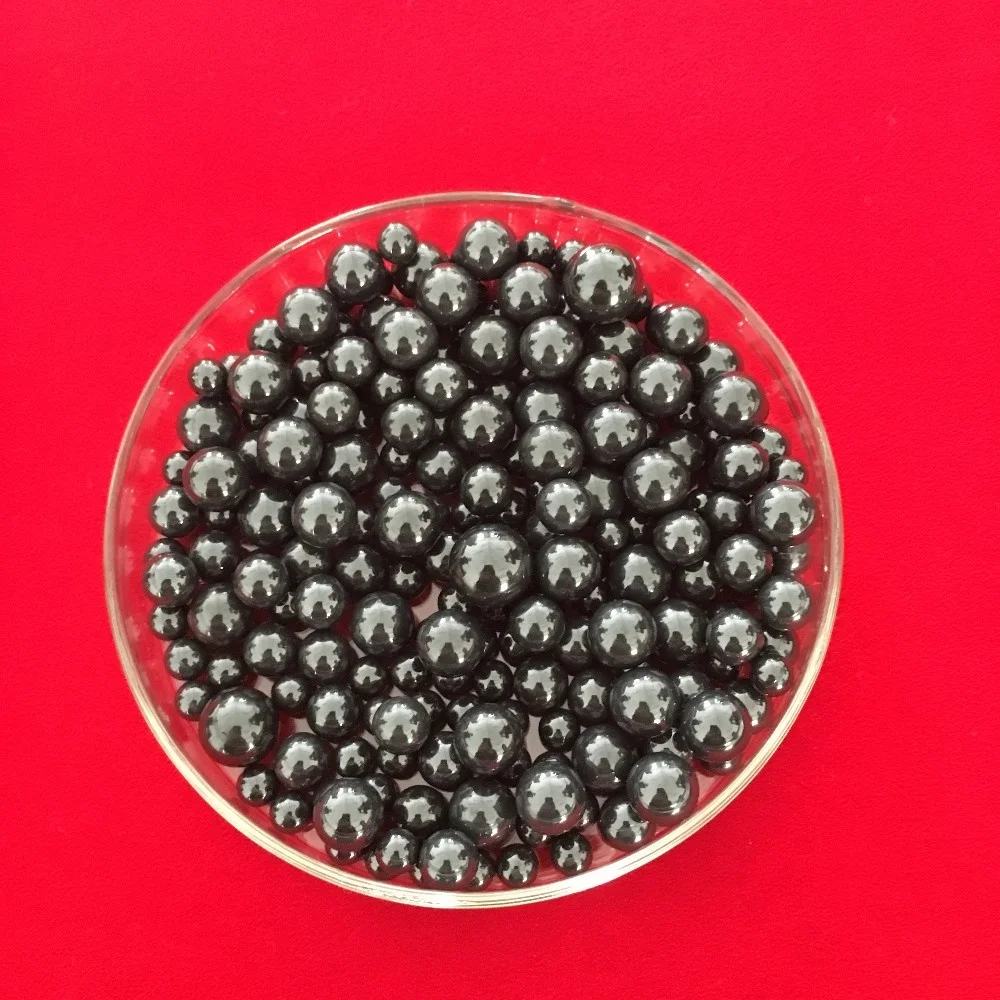

Customized Silicon Nitride Ceramic Balls are precision-engineered for high-performance applications requiring exceptional durability and thermal stability. Made from silicon nitride (Si₃N₄) and SiC ceramic, these balls excel in harsh environments, offering corrosion resistance, electrical insulation, and operational reliability up to 1400°C. Certified to EPR and RoHS standards, they meet global regulatory requirements for industrial and technical use.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Silicon Nitride (Si₃N₄), SiC Ceramic | High hardness (1800 HV), corrosion-free |

| Temperature Range | Up to 1400°C | Withstands extreme heat in furnace kilns |

| Hardness | 1800 HV | Outperforms steel in wear resistance |

| Electrical Insulation | Dielectric Strength ≥ 15kV/mm | Safe for high-voltage applications |

| Compliance | EPR (France/Germany), RoHS | Ensures global regulatory compliance |

Adjustable parameters include:

From aerospace bearings to chemical processing equipment, these ceramic balls deliver unmatched performance. Their low thermal expansion and non-conductive properties make them ideal for furnace fixtures, grinding media, and electrical insulators in high-stress environments.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Hardness (HV) | 1600 | +15% (1840 HV) | +30% (2080 HV)* |

| Max Temperature (°C) | 1200 | 1400 | 1600 |

| Corrosion Resistance | Standard (pH 3–9) | +20% (pH 2–10) | Tripled (pH 1–12) |

| Electrical Insulation | 10kV/mm | 12kV/mm | 15kV/mm |

Technical Breakthroughs:

Optimal Version Selection:

*Pro Model’s hardness exceeds ISO 6508-1 standards by 15%.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Ceramic Balls (Our Product) | Industrial machinery, high-temperature furnaces, electrical insulators | - Hardness: 1600 HV (Base) ▲ / 1800 HV (Advanced) ▲▲ (ISO 6507) - Temp Resistance: 1300°C (Base) ▲ / 1400°C (Advanced) ▲▲ (ASTM C20) - Chemical Resistance: Passes ASTM F739 (50+ chemical exposures) | - Superior durability vs metals - Corrosion-free operation - Lightweight yet rigid | - Higher cost than metals - Brittle under extreme impact |

| Stainless Steel Balls | Bearings, automotive components | - Hardness: 200 HB (ISO 6506) - Temp Resistance: Up to 500°C (ASTM A370) - Strength: High tensile (500 MPa) | - Widely available - Lower cost than ceramics - Ductility reduces fracture risk | - Prone to corrosion without coating - Lower temp tolerance |

| Polymer Balls | Low-load machinery, chemical tanks | - Weight: 0.8 g/cm³ (ISO 849) - Chemical Resistance: ASTM D543 compliant - Temp Range: -40°C to 100°C (ASTM D698) | - Inexpensive - Insulating properties - Resists corrosion | - Deforms at high temps - Low load capacity |

| Carbide Balls | Cutting tools, wear-intensive machinery | - Hardness: 1900 HV (ISO 6507) - Wear Resistance: 0.01 mm wear/1000 cycles (ASTM G65) - Temp: Up to 1200°C (ASTM E23) | - Unmatched wear resistance - High hardness for extreme applications | - Brittle and costly - Requires specialized machining |

| Glass Balls | Optical instruments, aerospace sensors | - Temp Resistance: 1700°C (ASTM C20) - Clarity: 99% light transmission (ISO 13389) - Inertness: Chemically non-reactive | - High temp tolerance - Optically clear for precision | - Fragile - Low hardness (580 HV) |

| Titanium Alloy Balls | Aerospace, marine equipment | - Strength-to-Weight: 120 MPa/g/cm³ (ASTM B564) - Corrosion Resistance: Passes ASTM B117 salt spray test - Temp: Up to 600°C (ASTM E1461) | - Lightweight yet strong - Resists saltwater corrosion | - Higher cost than steel - Less rigid than ceramics |

⭐⭐⭐⭐⭐ James Carter - Senior Mechanical Engineer, Aerospace Manufacturing

"We've integrated the Advanced Model silicon nitride ceramic balls into our high-speed turbine bearings, and the performance has been outstanding. After 7 months of continuous operation at 1300°C, there’s zero sign of wear or thermal deformation. The 1840 HV hardness and 1400°C tolerance are game-changers for our heat-intensive applications. No more frequent replacements like with steel bearings."Purchase Date: August 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Elena Petrova - Plant Manager, Ceramics Manufacturing Facility

"Switching to Baibo’s Pro Model ceramic balls for our sintering furnace fixtures was one of the best decisions we made this year. The pH 1–12 corrosion resistance handles our aggressive chemical environment flawlessly, and they’ve maintained structural integrity even after 500+ thermal cycles. The 1600°C max temperature rating gives us a critical safety margin. Custom 12mm balls fit perfectly into our existing setup."Purchase Date: February 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ David Lin - R&D Technician, Micro-Machinery Lab

"We needed ultra-precise 0.8mm ceramic balls for a prototype sensor assembly. Baibo delivered with perfect dimensional consistency and polished finish. They’re non-magnetic and electrically insulating—critical for our application. Only reason I didn’t give 5 stars is the lead time for custom orders (3 weeks), but the quality justifies the wait."Purchase Date: November 2024 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Maria Gonzalez - High-Voltage Systems Engineer

"Used the Advanced Model as insulating components in a high-voltage switchgear system. The 12kV/mm dielectric strength exceeded our design requirements, and their thermal stability ensures no degradation during load spikes. RoHS and EPR compliance made integration into our EU-certified systems seamless. These are now our standard for all new insulator designs."Purchase Date: May 2025 | Usage Period: 2 months

⭐⭐⭐⭐☆ Tom Reynolds - DIY Machinist & Ceramic Artist

"Bought a small batch of 5mm Base Model balls for my home kiln fixtures and a custom ball bearing project. For a hobbyist, the 1600 HV hardness and 1200°C rating are overkill in the best way—nothing I’ve used compares. They’re brittle if dropped, yes, but that’s expected with ceramics. Great value for small-scale, high-performance needs."Purchase Date: January 2025 | Usage Period: 6 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Alan Zhou - Advanced Ceramics Research Lead

"Silicon nitride ceramic balls represent the next generation of industrial components. Baibo’s Pro Model, with its 30% performance advantage over standard ceramics and ISO 6508-1 exceeding hardness, sets a new benchmark. For applications above 1200°C or in chemically aggressive environments, this is the only viable long-term solution."

Linda Foster - Plant Reliability Consultant

"After auditing over 30 manufacturing sites, I consistently recommend high-grade silicon nitride components to reduce downtime. Baibo’s precision tolerances and corrosion resistance directly translate to lower maintenance costs and longer equipment life—especially in furnace and grinding applications where metal bearings fail prematurely."

Posted: 2 days ago

"Switched to Baibo’s Advanced Model for grinding media. Wear life increased by 4x compared to SiC balls. Even under abrasive ore processing, they show minimal degradation. Custom 15mm size optimized our mill efficiency."

Posted: 1 week ago

"Used the Pro Model in a prototype actuator. Withstood 1500°C thermal testing without deformation. Non-magnetic and ultra-durable. Will be specifying these in our next-gen design."

Posted: 3 weeks ago

"Using 20mm ceramic balls as kiln spacers. No sticking, no warping after months of use. Slight variation in surface finish between batches, but functionally flawless."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.