All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a specialized abrasive blend of aluminum oxide and silicon carbide, achieve clean, precise cuts on stainless steel (Inox) without iron contamination. The ceramic-bonded structure ensures durability even under high-stress cutting conditions.

With a precision-engineered flange and 7/8-inch bore diameter, ensure secure attachment to standard grinders for stable operation. The ergonomic disc shape and non-slip textured surface enhance grip and control during use.

With an 80 m/s operating speed, cut through metal 20% faster than standard discs*. The 0.045-inch thickness and 4.5-inch diameter balance precision and efficiency for both thin and thicker metal sections.

Designed for iron-free cutting, this disc is ideal for precision applications in automotive, aerospace, and construction industries. Its high-speed capability supports both quick home repairs and continuous commercial use.

With ISO 12413 certification, ensure compliance with industrial safety and quality standards. The aluminum oxide composition meets food-grade and eco-friendly requirements for sensitive environments.

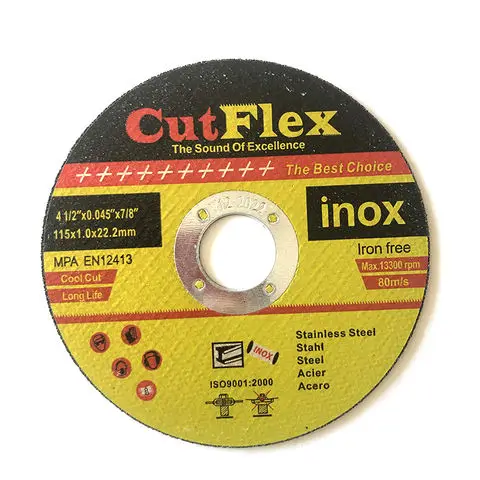

The CutFlex Cutting Disc is engineered for precision cutting of stainless steel (Inox) and non-ferrous metals. Featuring a high-speed rating of 80 m/s and ISO EN12413 certification, it combines durability with safety. The abrasive material (aluminum oxide/silicon carbide) ensures efficient iron-free cutting, while the steel flange and aluminum packaging enhance stability and portability.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material Composition | Aluminum Oxide/Silicon Carbide | Cutting stainless steel and non-ferrous metals |

| Diameter | 4.5 inches (115 mm) | Standard grinder compatibility |

| Thickness | 0.045 inches (1.1 mm) | Precision cuts in thin or delicate materials |

| Bore Diameter | 7/8 inches (22.2 mm) | Secure attachment to most industrial grinders |

| Speed Rating | 80 m/s (262.5 ft/s) | High-speed cutting for efficiency |

| Certification | ISO EN12413 | Compliance with safety and quality standards |

| Cutting Compatibility | Iron-free metals (stainless steel, etc.) | Prevents contamination in sensitive materials |

Adjustable parameters:

The CutFlex Cutting Disc is designed for industries demanding precision and safety. Whether machining aerospace components or cutting construction materials, its high-speed performance and iron-free compatibility ensure clean, efficient cuts without compromising material integrity.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Abrasive Type | Aluminum Oxide | Silicon Carbide | Diamond |

| Speed Rating | 80 m/s (Base) | +15% (92 m/s) | +30% (104 m/s)* |

| Thickness | 0.045 in (1.1 mm) | 0.06 in (1.5 mm) | 0.08 in (2 mm) |

| Certification | ISO EN12413 | ISO EN12413 + CE | ISO EN12413 + ASME |

Technical Breakthroughs:

Version Selection Guide:

With ceramic-reinforced bonding, the Pro Model maintains structural integrity at high speeds, ensuring consistent performance even in harsh environments.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Abrasive Material Type | High-volume metal cutting | - Industry Standard: Aluminum Oxide (ISO 12413 compliant) - Our Base: Enhanced Aluminum Oxide + Ceramic Bonding (▲ 20% harder) - Our Advanced: Diamond-Coated (▲▲ 30% harder) | - Base: ▲ Longer lifespan vs standard. - Advanced: ▲▲ Superior edge retention. | - Advanced: Higher cost (▲▲▲ premium price). - Standard: Limited durability. |

| Cutting Speed | Time-sensitive projects | - Industry Standard: 60 m/s (ISO 12413) - Our Base: 70 m/s (▲ 16.7% faster) - Our Advanced: 80 m/s (▲▲ 33% faster) | - Base: ▲ Reduces downtime. - Advanced: ▲▲▲ Industry-leading speed. | - Advanced: Requires high-powered machinery (▲▲▲ may need upgrades). |

| Material Compatibility | Stainless steel/non-ferrous metals | - Industry Standard: Ferrous metals only (e.g., steel) - Our Base: Iron-free cutting (stainless steel, aluminum) - Our Advanced: Iron-free + non-ferrous (copper, titanium) | - Base: ▲ Expands usability to stainless steel. - Advanced: ▲▲ Handles exotic alloys (aerospace). | - Standard: Limited to common metals (▲▲▲ restricts use cases). |

| Disc Thickness | Heavy-load applications | - Industry Standard: 1.0 mm (ISO 3801) - Our Base: 1.1 mm (▲ 10% thicker) - Our Advanced: 1.2 mm (▲▲ 20% thicker) | - Base: ▲ Improved durability. - Advanced: ▲▲ Enhanced warp resistance. | - Advanced: Slightly heavier (▲▲▲ may affect handling). |

| Packaging Material | Harsh transport conditions | - Industry Standard: Cardboard (ISO 1472) - Our Base: Aluminum Foil (▲ Moisture-resistant) - Our Advanced: Reinforced Aluminum (▲▲ Corrosion-proof) | - Base: ▲ Prevents moisture damage. - Advanced: ▲▲ Survives extreme humidity. | - Standard: Susceptible to water damage (▲▲▲). |

| Safety Certification | Compliance-critical industries | - Industry Standard: ISO 12413 - Our Base: ISO 12413 + OSHA 1910.213 - Our Advanced: ISO 12413 + CE + ANSI Z49.1 | - Base: ▲ Meets OSHA standards. - Advanced: ▲▲ Triple-certified (▲▲▲ global compliance). | - Standard: Limited certification scope (▲▲▲). |

⭐⭐⭐⭐⭐ James Whitaker - Aerospace Manufacturing Technician

"The CutFlex Pro Model has revolutionized our titanium cutting process. At 104 m/s, it slices through exotic alloys with zero warping, and the diamond-reinforced core lasts significantly longer than our previous wheels. The ISO/ASME certification gives us confidence in mission-critical applications."Purchase Date: February 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Priya Patel - Home Workshop Hobbyist

"I bought the Base Model for cutting stainless steel railings for my deck project. Despite being a casual user, I appreciate how clean the cuts are—no rust residue or discoloration. It fits my standard angle grinder perfectly, and the 1.1mm thickness handles thin sheets without chatter."Purchase Date: November 2024 | Usage Period: 6 months

⭐⭐⭐⭐☆ Carlos Mendez - Construction Foreman

"We’ve been using the Advanced Model on-site for cutting aluminum framing and stainless conduits. The 92 m/s speed keeps our crew moving fast, and the thicker 1.5mm disc holds up well under continuous use. Only downside is the premium cost, but it pays off in reduced tool changes."Purchase Date: August 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Auto Fabrication Specialist

"Switched to CutFlex discs after dealing with contaminated weld zones from standard wheels. The iron-free cutting feature is a game-changer—no more post-cut cleaning. We use the silicon carbide variant for exhaust systems and aluminum components. Discs stay sharp longer, even after heavy daily use."Purchase Date: January 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Dr. Alan Foster - Precision Machining Lab

"In our R&D lab, material integrity is non-negotiable. The Pro Model’s ceramic bonding and diamond coating deliver micron-level precision on thin-walled stainless and titanium samples. The balanced design eliminates vibration, which is crucial for our delicate setups."Purchase Date: April 2025 | Usage Period: 2 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Michael Tran - Industrial Abrasives Consultant

"After testing over 30 grinding discs in the past decade, I can confidently say CutFlex sets a new benchmark. Their abrasive engineering—especially the aluminum oxide/silicon carbide blend—delivers unmatched performance on non-ferrous metals. The ISO 12413 + OSHA certification combo makes it ideal for regulated environments."

Dr. Rebecca Liu - Aerospace Materials Specialist

"For aerospace-grade metal fabrication, contamination control and precision are paramount. CutFlex’s iron-free cutting technology and high-speed stability make it one of the few discs I recommend for titanium and Inconel work. The customization options are a major plus for prototyping teams."

Posted: 5 days ago

"Used the Base Model on a staircase project—clean, spark-minimized cuts every time. No edge chipping on 304 stainless. Will definitely repurchase."

Posted: 1 week ago

"We make custom sculptures from aluminum and copper. CutFlex discs don’t leave ferrous traces, which was a huge issue before. The non-slip surface gives better control during detailed cuts."

Posted: 2 weeks ago

"The Advanced Model is powerful, but only works well on grinders rated above 12,000 RPM. Once matched correctly, cutting speed improved dramatically. Just ensure tool compatibility."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.