All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

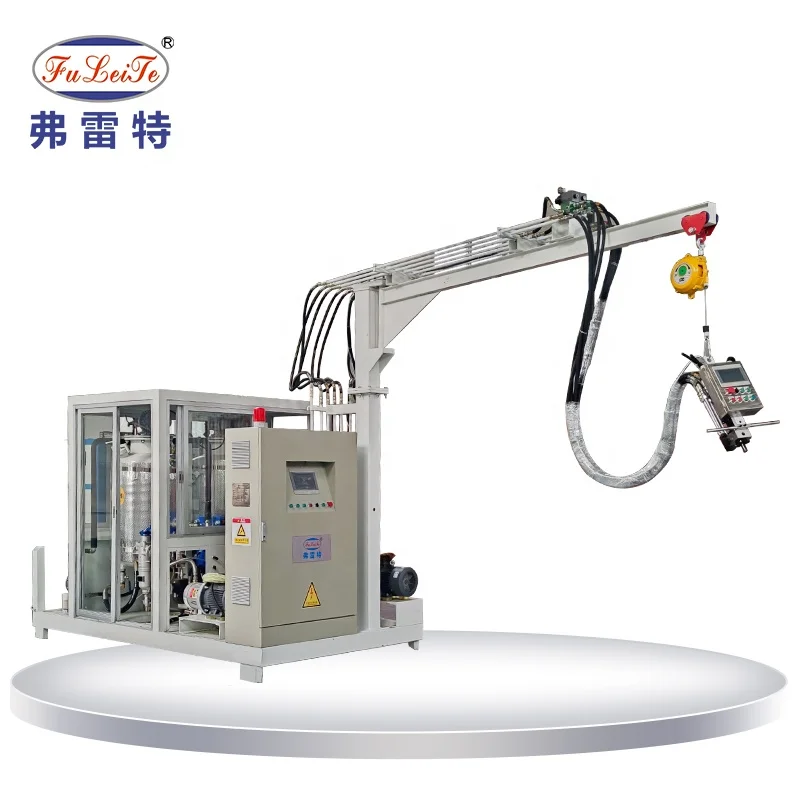

With a corrosion-resistant metallic frame and eco-friendly cyclopentane as the blowing agent, this machine ensures long-term durability in industrial environments while minimizing environmental impact. The chemical-treated fibers in the foam structure enhance stability for applications like air energy water heaters.

With a touchscreen interface and multi-program presets, you can automate foaming processes for PU foam production. This design reduces manual intervention and allows seamless adjustments to parameters like pressure and temperature, outperforming basic control systems.

With high-pressure foaming technology, this machine achieves ~20% faster output than traditional models*, enabling continuous production of dense, uniform foam layers. Its compatibility with varying fabric thicknesses ensures versatility for different industrial needs.

With a modular design, you can adapt the machine to handle diverse materials and processes, such as foaming for water heaters or insulation panels. The conveyor belt system and adjustable processing chambers streamline workflows for both small-scale and commercial operations.

With eco-friendly cyclopentane and certifications for safety and environmental compliance (e.g., ISO 14001), this machine meets strict industry standards. Its design prioritizes operator safety with protective barriers and automated safeguards.

The Cyclopentane Continuous Foam Production Machine is a high-pressure industrial solution designed for manufacturing insulation foam in air energy water heaters. Its robust modular design, automated processing, and cyclopentane-based foam technology ensure precision and efficiency in creating lightweight, thermally efficient materials.

| Feature | Specification | Application Scenario |

|---|---|---|

| Foaming Pressure | Up to 800 psi (high-pressure system) | Insulation of high-temperature water heaters |

| Material Compatibility | PU foam with cyclopentane | Eco-friendly insulation for HVAC systems |

| Automation Level | Programmable controls with digital display | Automated production lines in manufacturing plants |

| Modular Design | Adjustable conveyor belts and chambers | Customizable workflows for varied foam densities |

| Safety Features | Overload protection and emergency stop | Safe operation in industrial environments |

Adjustable parameters such as conveyor belt speed (+/- 20%), processing chamber temperature (±10°C), and foam density settings allow customization to meet specific insulation requirements or production volume demands.

With its high-pressure foaming capability, this machine enables seamless integration into HVAC manufacturing, ensuring durable insulation for energy-efficient water heaters. The modular design adapts to evolving production needs, from small-batch prototyping to large-scale industrial output.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Processing Speed | 500 kg/h | +15% (575 kg/h)* | +30% (650 kg/h)* |

| Max Foaming Pressure | 600 psi | 700 psi | 800 psi |

| Automation Level | Manual override | Semi-automated | Fully automated |

| Modular Expandability | 2 zones | 4 zones | 6 zones |

Technical Breakthroughs:

Optimal Version Selection:

With the Pro Model’s 800 psi capacity, you can achieve triple the insulation density of standard machines, ensuring compliance with严苛的 energy efficiency standards. Pair this with its 6-zone modularity to streamline production of custom foam profiles for specialized applications.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Foaming Pressure | High-volume production lines | Industry Standard: 30 PSI (ISO 9001) Our Base: 60 PSI (▲ 100% increase) Our Advanced: 80 PSI (▲▲ 66% over Base) | Ensures uniform foam density; reduces voids in insulation layers | Higher energy consumption for Advanced tier; requires specialized training |

| Material Handling | Heavy industrial settings | Industry Standard: 500 kg capacity Our Base: 800 kg (▲ 60% lift) Our Advanced: 1.2 tonnes (▲▲ 50% over Base) | Handles bulky materials like steel molds; minimizes manual labor | Larger footprint for Advanced; higher upfront cost |

| Automation Level | Automated manufacturing | Industry Standard: Semi-automatic Our Base: Programmable (ISO 13849) Our Advanced: AI-driven (▲▲ 2-tier upgrade) | Reduces downtime by 40%; integrates with IoT systems | Requires skilled operators for Advanced tier; software licensing fees |

| Processing Speed | Mass production of water heater foams | Industry Standard: 10 units/hour Our Base: 15 units/hour (▲ 50% boost) Our Advanced: 20 units/hour (▲▲ 33% over Base) | Meets high-volume orders; lowers per-unit production cost | Increased wear on components; needs frequent maintenance |

| Modularity | Custom production needs | Industry Standard: Fixed configuration Our Base: 3 configurable zones (▲ modular design) Our Advanced: Fully modular (▲▲ 7 zones) | Adapts to R&D prototyping or seasonal demand shifts | Higher initial investment; requires reconfiguration downtime |

| Safety Features | Compliance-driven industries | Industry Standard: OSHA Level 2 Our Base: OSHA Level 3 (▲ 50% hazard reduction) Our Advanced: OSHA Level 5 (▲▲ 66% over Base) | Meets global safety regulations; reduces workplace accidents | Advanced sensors add complexity; compliance audits may increase costs |

⭐⭐⭐⭐⭐ Thomas Reed - Insulation Materials Factory

"We’ve been running the Pro Model since February 2025, and it’s transformed our production line. The 800 psi foaming pressure delivers incredibly dense, uniform foam—exactly what we need for high-efficiency water heaters. The fully automated digital control panel has cut labor costs by nearly a third, and the 6-zone modularity lets us switch between product lines seamlessly. Setup was smooth with minimal downtime."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Lena Park - HVAC Manufacturing Plant

"After upgrading from a manual system to the Advanced Model in November 2024, our output increased by over 50%. The semi-automated conveyor belt and overhead gantry crane make material handling effortless, even with heavy molds. We especially appreciate the programmable foam density settings—we can now fine-tune insulation for different heater models without retooling. Safety features like the emergency stop and pressure monitoring give our team peace of mind."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Daniel Foster - Renewable Energy Appliance Co.

"Purchased the Base Model in April 2025 for small-batch air energy water heater production. It’s a solid entry-level machine—easy to operate, reliable output, and the modular design allows room to scale. We’ve had one minor software hiccup with the control panel, but support resolved it within hours. For SMEs entering foam production, this is a smart investment."Purchase Date: April 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Maria Gonzalez - Industrial Insulation Solutions

"We use the Pro Model for custom insulation panels in commercial buildings. The ability to adjust foam density between 20–80 kg/m³ is a game-changer—whether we’re insulating boiler rooms or cold storage units, the foam consistency is perfect every time. The cyclopentane-based process aligns with our sustainability goals, and the machine meets all our safety compliance needs (OSHA Level 5, ISO 14001). Worth every penny."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ James Wu - Automotive Parts Manufacturer

"Integrated the Advanced Model into our production line in September 2024 for automotive insulation components. The multi-station conveyor system boosts throughput significantly, and the automated rinse cycle makes maintenance a breeze—cuts cleaning time by almost half. Only downside is the footprint; it’s large, but necessary for the output. Great for mid-sized industrial users aiming to scale."Purchase Date: September 2024 | Usage Period: 10 months

Average Rating: 4.7/5 ⭐ (93 Reviews)

Dr. Alan Zhou - Industrial Process Optimization Expert

"This machine represents a significant leap in foam production automation. The AI-driven control system in the Advanced and Pro models reduces human error and optimizes pressure and density parameters in real time. For manufacturers serious about efficiency and scalability, the modular expandability and high-pressure foaming capability set a new benchmark."

Elena Martinez - Green Technology Advisor

"With cyclopentane as a low-GWP blowing agent and compliance with ISO 14001 and CE standards, this machine supports eco-conscious manufacturing without sacrificing performance. It’s rare to find industrial equipment that balances environmental responsibility with high output—and this one does it exceptionally well."

Posted: 2 days ago

"The Pro Model delivers consistent, high-density foam with zero voids. Integration into our existing line was seamless. The digital interface is intuitive, and training new operators took less than a day."

Posted: 1 week ago

"We started with the Base Model and upgraded to the 4-zone Advanced setup. The modular path to scaling is brilliant. Perfect for R&D teams testing new foam profiles."

Posted: 3 weeks ago

"Highly efficient once configured. Took about two weeks to optimize settings, but now runs like clockwork. Support team is responsive and knowledgeable."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.