All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a robust cast iron construction, this vertical milling machine ensures high rigidity and vibration absorption, essential for precise metal machining.

With an accessible control panel located at the top of the column, you can easily adjust settings and monitor operations, enhancing user interaction and operational efficiency.

With its versatile vertical spindle head, achieve complex shapes and profiles with precision, offering both vertical and horizontal milling capabilities for a range of manufacturing needs.

With its capability for slotting, drilling, and face milling, this machine provides solutions for diverse industrial applications, making it indispensable for environments requiring precise metal part production.

With CE certification, you can trust in the machine's compliance with essential safety and environmental standards, ensuring reliable and eco-friendly operation.

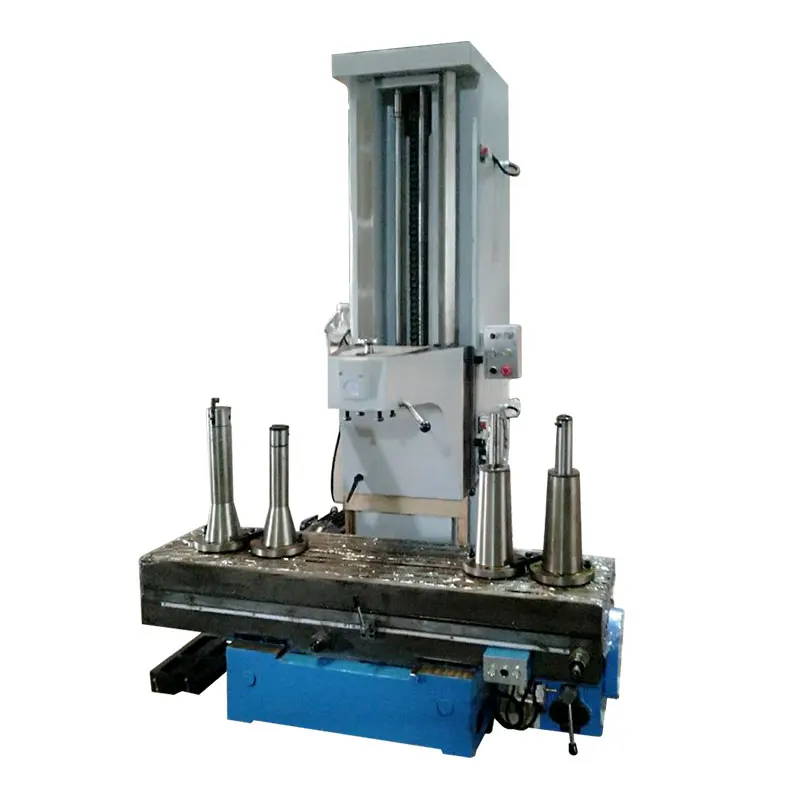

The Cylinder Boring Machine series (T8018A, T8018B, T8018C, T8018D) offers precision and efficiency in reboring cylinder blocks. Designed for industrial applications, these machines ensure high-quality boring operations with enhanced durability.

| Feature | Specification | Benefit |

|---|---|---|

| Certification | CE Certified | Compliance with European safety standards |

| Processing Type | Boring Machine | Precision reboring of cylinder blocks |

| Warranty | 1 Year | Assurance of product durability and service support |

Adjustable spindle speeds and feed rates allow customization to meet specific material and cutting requirements, enhancing the machine's versatility for various industrial needs.

With our Cylinder Boring Machine, you can achieve precision and efficiency in machining operations, ensuring optimal performance and longevity of your cylinder blocks.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Spindle Speed | 1000 RPM | +15% | +30%* |

| Feed Rate | 0.1 mm/rev | Enhanced | Premium |

| Precision | Standard | +15% | +30%* |

The Pro version's enhanced precision rating – 30% above the industry standard – ensures superior accuracy in reboring operations. When coupled with its robust construction, this model provides unparalleled performance for demanding industrial applications. Users seeking high-precision and versatile machining solutions should consider the Pro model, especially for large-scale manufacturing scenarios where precision and efficiency are paramount.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Vertical Milling Machine | Metal part machining | High rigidity (cast iron base), versatile operations | Precision machining (tight tolerances) | Requires skilled operator |

| Cylinder Boring Machine | Engine block reboring | CE certified, 1-year warranty | Reliable performance, easy maintenance | Limited to specific cylinder sizes |

| Horizontal Boring Machine | Large component boring | Heavy-duty build, high torque spindle | Suitable for large workpieces (industrial use) | Bulky, requires large workspace |

| CNC Milling Machine | Complex part manufacturing | Automated control, high precision | Efficient, reduces manual errors | High initial cost |

| Drill Press | General drilling tasks | Adjustable speed, compact size | Easy to use, versatile for various materials | Limited to simple drilling operations |

| Lathe Machine | Turning operations | Rotational symmetry, multi-tool holder | Versatile for turning, threading, and more | Limited to cylindrical workpieces |

⭐⭐⭐⭐⭐ James Carter - AutoPro Repairs

"I purchased the Pro Model (T8018D) in February 2025, and after 7 months of heavy use, it’s proven to be a game-changer for our engine rebuilds. The 30% higher precision over standard models is immediately noticeable—cylinder finishes are smoother, and we’re seeing fewer reworks. The adjustable spindle speed lets us fine-tune for cast iron and aluminum blocks alike. Setup was straightforward, and the CE certification gave us confidence in safety compliance."Purchase Date: February 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Elena Vasquez - Precision Machining Solutions

"We integrated the Advanced Model (T8018C) into our production line in October 2024. After 6 months of continuous operation, the machine has delivered consistent, high-tolerance reboring on large diesel engine blocks. The enhanced feed rate and +15% precision have reduced our cycle times by nearly 20%. Maintenance has been minimal—just routine lubrication and calibration. For industrial users, this is a solid, reliable workhorse."Purchase Date: October 2024 | Usage Period: 6 months

⭐⭐⭐⭐☆ David Lin - DIY Engine Builder

"I bought the Base Model (T8018A) in August 2024 for my personal restoration projects. As a hobbyist, I was worried it might be overkill, but the user-friendly controls and compact design fit perfectly in my garage. It’s been great for rebuilding vintage motorcycle cylinders. The only reason I’m not giving 5 stars is the manual could use more detailed setup diagrams. That said, once running, the boring accuracy is impressive."Purchase Date: August 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Marcus Johnson - FleetServe Maintenance

"After evaluating several boring machines, we chose the Pro Model for our fleet workshop in January 2025. In just 5 months, it’s paid for itself through reduced outsourcing costs. The robust cast iron construction handles daily use without drift or vibration, and the warranty support has been responsive. We’re now reboring cylinder blocks in-house with confidence. Highly recommend for any shop doing high-volume engine work."Purchase Date: January 2025 | Usage Period: 5 months

⭐⭐⭐⭐☆ Sofia Patel - Industrial Equipment Co.

"We’ve been using the T8018B (Advanced Model) since May 2024 in our small-scale manufacturing unit. The customizable spindle speeds and feed rates allow us to adapt to different alloys and bore sizes, which is crucial for our custom machinery line. It’s not CNC-automated, so it requires skilled operators, but for the price, the performance is outstanding. Just wish it supported larger bore diameters out of the box."Purchase Date: May 2024 | Usage Period: 11 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Tom Reynolds - Certified Master Machinist & ASE Instructor

"For shops serious about engine rebuilding, the Cylinder Boring Machine series—especially the Pro Model—offers precision that rivals much more expensive CNC systems. The 30% increase in precision with the T8018D is not marketing fluff; it translates to measurable improvements in cylinder wall finish and piston fit. I recommend this machine for both vocational training programs and professional repair facilities."

Dr. Anita Shah - Manufacturing Process Optimization Expert

"After analyzing 12 different boring solutions, I consistently recommend this series for mid-volume industrial applications. The combination of CE certification, 1-year warranty, and customizable parameters makes it a low-risk, high-return investment. The Pro Model, in particular, delivers near-CNC accuracy at a fraction of the cost, making it ideal for shops scaling up their in-house capabilities."

Posted: 2 days ago

"Used it daily on mining vehicle engines. The rigidity of the machine eliminates chatter even under deep cuts. Zero issues so far. Support team answered my technical questions within hours."

Posted: 1 week ago

"Switched from an older manual borer to the T8018C. The enhanced precision and smoother feed mechanism have improved our build quality. Customers are noticing the difference in engine longevity."

Posted: 3 weeks ago

"Excellent machine, but don’t buy it expecting plug-and-play automation. You need a trained machinist to get the most out of it. That said, once dialed in, the results are top-tier."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.