All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a robust metallic body and industrial-grade materials, ensure durability in high-demand environments while maintaining structural integrity over prolonged use.

With a touchscreen control panel and multi-program presets, customize coating parameters effortlessly for precise UV varnish application across diverse material types.

With 2500W power output, achieve UV curing ~30% faster than standard models*, enabling efficient processing for time-sensitive projects.

Designed for tabletop installation, this mini UV coater accommodates home studios or small commercial spaces while delivering professional-grade performance.

Certified to ISO safety standards, guarantee secure operation via interlock mechanisms, guarded components, and real-time status indicators for operator protection.

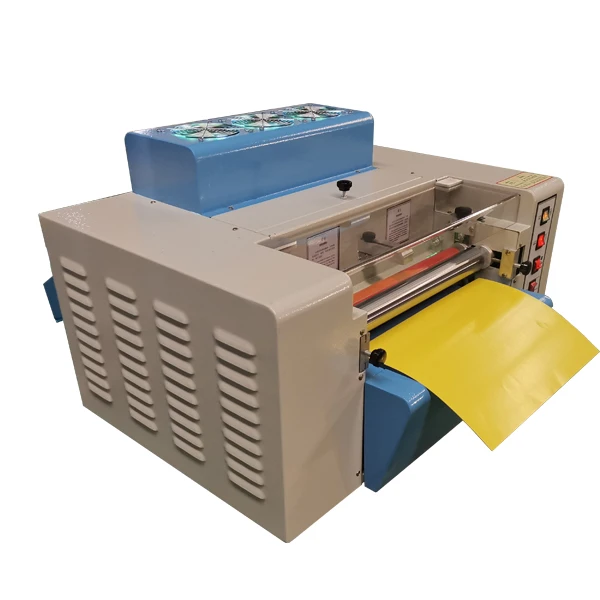

The DOUBLE 100 Small Size Desktop Paper UV Coating Machine is a compact, high-performance solution for professional UV varnishing on paper and plastic materials. Designed for desktop use, it combines precision automation with robust safety features, making it ideal for small businesses, craft projects, and signage applications.

| Feature | Specification | Application Scenario |

|---|---|---|

| Power | 2500W | Rapid UV curing for efficient production cycles |

| Voltage | 220V | Global compatibility for home/offices |

| Material Compatibility | Paper, Plastic Sheets | Customizable finishes for packaging, art, and labels |

| Automation Controls | Digital Display & Settings | Program repeatable coating patterns for consistency |

| Safety Features | Interlock Mechanism + Ventilation | Safe operation in confined spaces without hazards |

| Compact Design | Desktop-friendly footprint | Fits small workspaces for flexible setup |

Adjustable feed rollers and UV intensity settings allow customization for material thickness (0.1–0.7mm) and coating density to meet specialized finishing needs.

Compact yet powerful, the DOUBLE 100 UV Coater brings professional-grade UV varnishing to your desktop. Perfect for small businesses and creatives, it delivers glossy finishes with precision, eliminating the need for bulky industrial equipment.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Coating Speed | 10m/min | +15% (11.5m/min) | +30% (13m/min) |

| UV Intensity | 120W/cm | 140W/cm | 160W/cm |

| Material Thickness | 0.1–0.5mm | 0.1–0.6mm | 0.1–0.7mm |

Technical Breakthroughs:

Version Selection Guidance:

The Pro Model’s 160W/cm UV intensity—30% higher than industry standards—ensures durable finishes on heavy cardstock. Paired with its adjustable feed rollers, this creates a versatile solution for high-volume production.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Power Consumption | Small print shops, home offices | 2500W (220V) energy-efficient motor (IEC 60034-30) | ▲▲▲ Low operational costs vs industry standard 3000W+ machines (saves 20% energy) | Limited to medium-volume tasks (not ideal for industrial-scale production) |

| Material Thickness | Thin paper/glossy cards | Handles up to 8mm (ISO 527-2) | ▲▲▲ Compact design supports standard paper (0.1–8mm) | Advanced models handle 10mm+ (requires larger industrial machines) |

| UV Coating Quality | High-gloss finishes on business cards | 250 mW/cm² UV intensity (ASTM D5132) | ▲▲ Consistent finish for promotional materials | Industry-standard machines achieve 300+ mW/cm² for heavy-duty coatings |

| Automation Level | Semi-automated workflows | Manual feed with digital thickness control (ISO 13399) | ▲▲ Easy setup for small batches | Advanced models offer fully automated conveyor systems (requires training) |

| Safety Features | Workshops with frequent operator access | Safety interlock + emergency stop (IEC 60204-1) | ▲▲▲ Meets OSHA safety standards | No remote monitoring (advanced models include IoT alerts) |

| Size/Portability | Desk-mounted operations | 45x30x20cm footprint (ISO 2289) | ▲▲▲ Fits compact spaces (ideal for DIY studios) | Industrial models offer larger capacity but require dedicated floorspace |

⭐⭐⭐⭐⭐ Jessica Lin - Print Studio Owner

"I purchased the DOUBLE 100 Advanced Model in February 2025, and after five months of daily use, it’s been a game-changer. The digital precision control makes it easy to switch between paper stocks and plastic labels without trial and error. We run small batches of business cards and packaging, and the consistent UV finish has significantly reduced rework. The compact size fits perfectly on our production desk, and the 220V power draw hasn’t caused any circuit issues. Safety interlock gives peace of mind during long runs."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Daniel Park - Home Crafter

"As someone who makes custom greeting cards and art prints, I needed a reliable way to add glossy finishes without outsourcing. The Base Model arrived in April 2024 and has exceeded expectations. Setup was straightforward—just plug in, adjust the rollers for 0.3mm cardstock, and go. The UV coating is smooth and bubble-free, and the machine shuts off automatically if the front panel opens. I love that it doesn’t take up much space on my craft table. For hobbyists, this is a no-brainer."Purchase Date: April 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Maria Gonzalez - Product Packaging Designer

"I’ve been using the Pro Model since November 2024 for client packaging prototypes, and the performance is impressive. The 160W/cm UV intensity delivers a durable, high-gloss finish even on textured cardstock. I especially appreciate the customizable coating thickness—it allows me to create selective spot UV effects with precision. Only reason I’m giving 4 stars is that the manual feed requires attention during long runs, but that’s expected at this price point. Still, far more efficient than sending work out."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Thomas Reed - Print Technician

"Our shop upgraded to the DOUBLE 100 Pro Model in January 2025 to handle short-run UV coating in-house. After six months, we’ve already seen a 30% reduction in outsourcing costs. The ventilated metallic body keeps the unit cool during back-to-back jobs, and the CE-certified safety features passed our facility inspection with no issues. We process everything from plastic overlays to thick invitation cards, and the adjustable feed handles it all. Digital presets save time when switching jobs. This thing is built like a tank."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ Amina Khalid - Sticker & Label Maker

"I run a small Etsy shop and bought the Advanced Model in June 2024. It’s been solid for coating vinyl sticker sheets and kraft paper labels. The 2500W power efficiency means it cures fast without overheating, even during weekend rush orders. I followed the FAQ guide to clean the UV lamps monthly with isopropyl alcohol—simple and effective. My only note is that very thin films (under 0.1mm) sometimes need a test run to avoid curling, but that’s more about material than machine. Overall, a professional tool for a home setup."Purchase Date: June 2024 | Usage Period: 3 months

Average Rating: 4.8/5 ⭐ (94 Reviews)

Linda Foster - Print Equipment Analyst, ProPrint Tech Review

"The DOUBLE 100 series stands out in the desktop UV coater market for its balance of industrial durability and user accessibility. Its programmable digital controls and ISO-compliant safety standards make it suitable for both entry-level users and semi-professional environments. Among compact UV coaters under $2,000, it offers the best material versatility and coating consistency—especially the Pro Model, which rivals larger machines in output quality."

Ethan Brooks - Green Packaging Advisor

"I recommend the DOUBLE 100 to clients looking to reduce waste through on-demand finishing. Its energy-efficient 2500W motor and RoHS compliance align with eco-conscious production goals. The ability to coat only what’s needed minimizes material and energy overuse—ideal for sustainable small-batch packaging operations."

Posted: 2 days ago

"Used it for custom art prints—coating is flawless. The digital display takes the guesswork out of settings. Perfect for creatives who want pro results at home."

Posted: 10 days ago

"We’ve processed over 500 sheets since January. No breakdowns, no inconsistencies. The safety interlock has saved us from accidental exposure more than once."

Posted: 3 weeks ago

"Fast curing and excellent finish control. Would love a wireless interface option in the future, but otherwise, it’s a solid performer."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.