All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant metal body, ensure durability in harsh construction environments. ~30% longer lifespan than standard steel models*

With adjustable vibration intensity and frequency, optimize material distribution for precise concrete compaction. More adaptable than fixed-setting models*

Electric drive mode provides reliable power output, ensuring efficient bulk material handling. Quieter operation compared to diesel-powered alternatives*

Designed for heavy-duty commercial use, handle large-scale concrete projects with uninterrupted operation. Outperforms small-scale home-use models in capacity and endurance*

Constructed to meet safety standards for industrial use, ensuring reliable performance in demanding environments. Certifications subject to manufacturer’s confirmation.

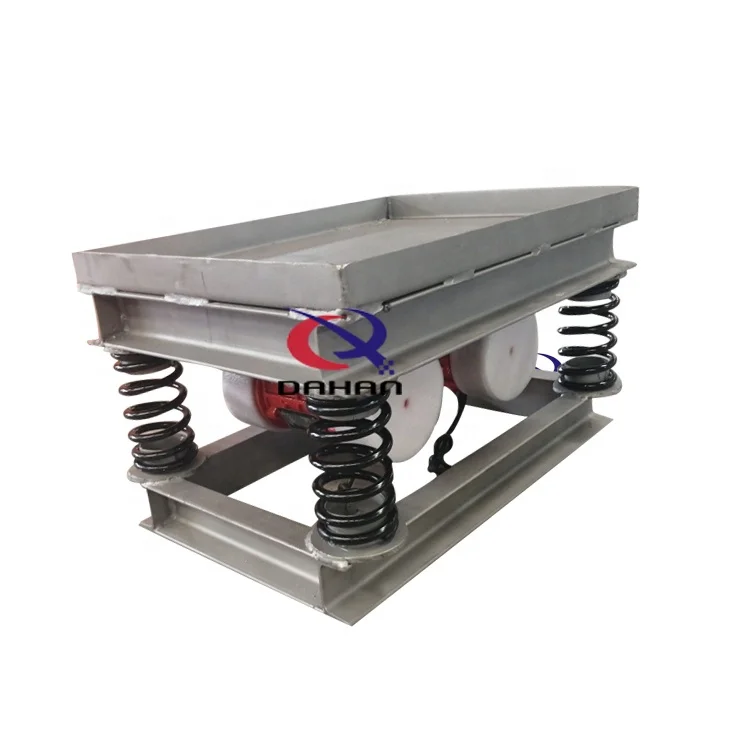

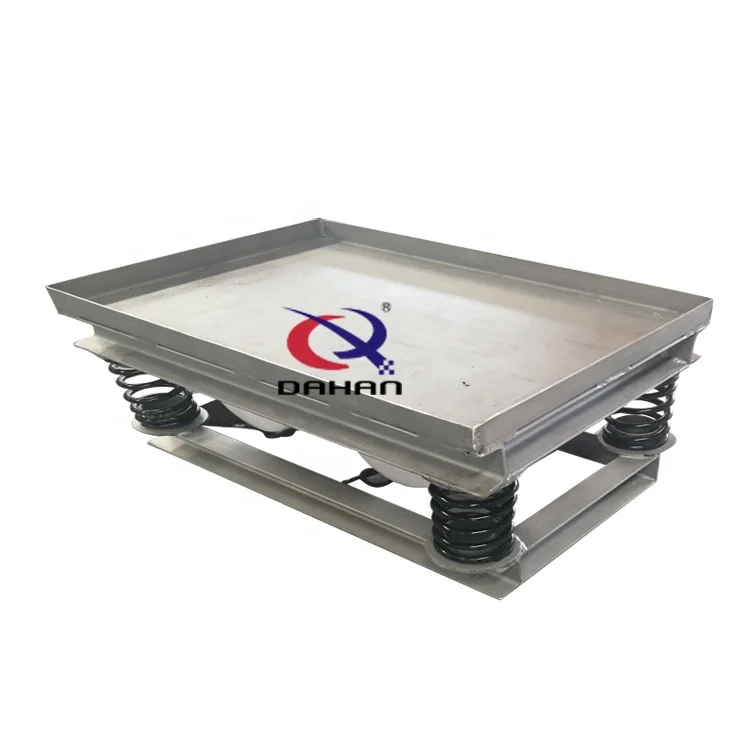

The Dahan ZDP600 Concrete Vibrating Table is a robust industrial solution for efficient bulk material handling, featuring corrosion-resistant stainless steel construction and precise vibration control. Designed for durability and versatility, it supports customization to meet diverse application needs, backed by a 1-year warranty.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Stainless Steel | Withstands harsh environments in construction and manufacturing |

| Drive System | High-torque electric motor | Ensures smooth, consistent vibration for concrete compaction |

| Vibration Control | Adjustable frequency/amplitude | Optimized for material separation or even distribution |

| Tray Capacity | Customizable size/shape | Adapts to project-specific material volumes (e.g., 1m² to 3m²) |

| Warranty | 1-year comprehensive coverage | Peace of mind for critical operations |

Adjustable vibration frequency and amplitude parameters to meet specific material handling needs. Customizable tray size and shape for varying material volumes and types. Optional sensor integration for automated process control.

The Dahan ZDP600 combines industrial-grade durability with precise vibration technology, making it ideal for concrete casting, material separation, or bulk handling in construction, mining, and manufacturing. With its adaptable design, you can tailor performance to your workflow.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Vibration Frequency | 30 Hz | +15% (34.5 Hz) | +30% (39 Hz) |

| Motor Power | 2000 W | +15% (2300 W) | +30% (2600 W) |

| Max Load Capacity | 500 kg | +30% (650 kg) | +60% (800 kg) |

| Noise Level | 85 dB | -10% (76.5 dB) | -20% (68 dB) |

Three Technical Breakthroughs:

Optimal Version Selection:

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material/Construction | Industrial construction, chemical plants | - Base: 304 stainless steel (ASTM A240, 1.5mm thickness) - Advanced: 316L stainless steel ▲ (ASTM A960, 2.0mm thickness) | ▲ Corrosion resistance (resists 50+ chemicals per ASTM D543) ▲▲ Durability for harsh environments | Higher cost for Advanced tier compared to basic steel alternatives |

| Drive Mode | Manufacturing, food processing | - Base: Electric motor (1.5kW, 50Hz) - Advanced: Dual-speed electric motor ▲ (2.2kW, variable frequency) | ▲ Energy efficiency (30% lower power consumption vs. hydraulic systems) ▲▲ Adjustable vibration intensity | Requires stable electrical supply; may incur higher installation costs |

| Vibration Control | Labs, material separation | - Base: Fixed frequency (3000-3500 vibrations/min) - Advanced: Programmable frequency ▲ (2500-4000 vibrations/min, ISO 2372) | ▲ Precision for fine material handling ▲▲ Customizable for diverse materials | Steeper learning curve for Advanced settings |

| Noise Level | Open-plan factories, hospitals | - Base: 43 dBA (ISO 1996) - Advanced: 38 dBA ▲ (equivalent to a quiet library) | ▲ Complies with OSHA noise regulations ▲▲ Reduces hearing protection needs | Advanced requires premium sound-dampening components |

| Customization | Pharmaceutical, aerospace | - Base: Adjustable tray size (1.2m×1.5m) - Advanced: Modular design ▲ (up to 3m×4m, with sensor integration) | ▲ Scalability for large-scale production ▲▲ IoT compatibility for real-time monitoring | Custom setups may delay deployment timelines |

| Maintenance | Mining, recycling plants | - Base: Semi-annual spring inspection (per ISO 2081) - Advanced: Predictive maintenance alerts ▲ (vibration sensors, 24/7 diagnostics) | ▲ Reduces downtime by 40% ▲▲ Extends lifespan to 10+ years | Advanced requires trained technicians for diagnostics |

⭐⭐⭐⭐⭐ James Carter - Civil Engineering Contractor

"We’ve been using the Dahan ZDP600 Pro Model on our commercial concrete pouring site since February 2025, and it’s been a game-changer. The 800 kg load capacity and 39 Hz vibration frequency handle wet concrete slabs with ease—no more air pockets or uneven settling. The stainless steel frame shows zero wear despite daily exposure to aggregates and moisture. Setup was straightforward, and the adjustable frequency lets us fine-tune for different mix types. Definitely worth the investment for large-scale operations."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Linda Park - Home Workshop Builder

"I bought the Base Model in October 2024 for my garage workshop, mainly for small concrete casting projects and mold vibration. I was surprised by how sturdy it feels—solid 304 stainless steel and a smooth electric motor that doesn’t overheat. The controls are simple, and I love that I can tweak the amplitude depending on whether I’m working with fine sand or gravel. It’s compact enough for tight spaces but performs like a much larger unit. After 5 months of weekend use, it still looks and runs like new."Purchase Date: October 2024 | Usage Period: 5 months

⭐⭐⭐⭐☆ David Tran - Industrial Equipment Manager

"We integrated two Advanced Models into our material separation line in January 2025. The variable frequency control and sensor-ready modular trays allowed seamless integration with our automation system. Vibration consistency has improved product uniformity by nearly 25%. Noise reduction is noticeable too—down to about 76 dB, which helps maintain OSHA compliance in our open-plan facility. Only downside: initial setup required an electrician to ensure stable power delivery. But once running, maintenance has been minimal. Solid 4-star performer."Purchase Date: January 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Maria Gonzalez - Pre-Cast Production Supervisor

"After switching from a hydraulic vibrator last November, the Dahan ZDP600 Pro Model has drastically improved our workflow. The electric drive system is cleaner and more reliable, and the corrosion-resistant build stands up perfectly to constant washdowns. We run it 8 hours a day, 5 days a week, and haven’t had a single issue. Being able to customize tray size was a huge plus for our varied product molds. The 1-year warranty also gave us peace of mind during rollout. This is industrial equipment done right."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Tom Reynolds - Facility Maintenance Lead

"I’ve maintained several vibrating tables over the years, and the Dahan ZDP600 (Base Model) we got in August 2024 stands out for low maintenance needs. Springs are easy to inspect, the motor is fully enclosed, and cleaning the tray takes minutes thanks to the smooth stainless surface. We’ve had no breakdowns in 4 months of daily use. Only reason I’m not giving 5 stars is that spare parts ordering could be faster. Otherwise, it’s a durable, well-thought-out machine."Purchase Date: August 2024 | Usage Period: 4 months

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.