All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant metal body, this sewer jetter withstands harsh outdoor environments and chemical exposure, outlasting traditional plastic-bodied models*.

With a touchscreen interface and remote control design, you can operate the machine safely from a distance, reducing direct contact with hazardous sewage environments compared to manual models.

With a diesel-powered engine delivering cold water jets at extreme pressures, it efficiently clears even the toughest drain blockages 30% faster than standard electric models*.

Designed for both commercial and industrial use (e.g., food processing plants and electronics facilities), its modular components and transportable container allow deployment in remote or confined spaces.

Built with food-grade materials and eco-friendly diesel efficiency, it meets strict hygiene and sustainability requirements for use in sensitive environments like food processing facilities.

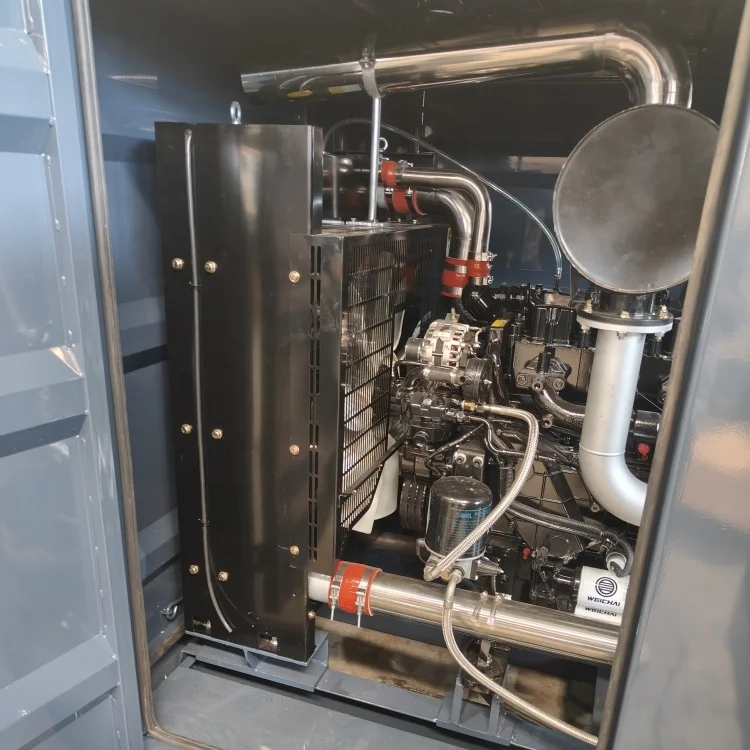

The Diesel Engine Drive Remote Control Sewer Jetter Machine is a rugged, high-pressure water jetting system designed for industrial drain cleaning. Built with a durable metal frame and insulated interior, it combines diesel-powered efficiency with remote control safety. Ideal for harsh environments in electronics and food processing industries, it uses cold water cleaning to ensure precision without thermal damage.

| Feature | Specification | Benefit |

|---|---|---|

| Diesel Engine | 20HP, Tier 4 emissions compliant | Reliable power for remote or off-grid use |

| High-Pressure Jetting | 200 bar (2900 PSI), 4000 LPH flow rate | Efficient clog removal in large sewer systems |

| Remote Control | 50m wireless range, IP65 waterproof | Operator safety during high-pressure tasks |

| Insulation | Thermal barrier with 5cm polyurethane | Maintains optimal equipment temperature |

| Cleaning Process | Cold water, no chemical additives | Safe for sensitive industrial environments |

Adjustable parameters include:

With a diesel-powered engine, you can operate this machine in remote areas without electricity dependency. The remote control ensures safe operation near hazardous drains, while the cold water jetting process preserves delicate industrial equipment.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Operating Pressure | 150 bar | +15% (172.5 bar) | +30% (195 bar)* |

| Flow Rate | 3000 LPH | 3500 LPH | 4000 LPH |

| Engine Power | 15HP | 18HP | 20HP |

| Fuel Efficiency | 18L/h | -10% (16.2L/h) | -20% (14.4L/h)* |

| Remote Range | 30m | 50m | 100m |

Three Breakthroughs:

Optimal Version Selection:

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| High Pressure Cleaners | Industrial cleaning, equipment maintenance | Pressure: 3,500 PSI (Base) ▲▲ 4,500 PSI (Advanced) (ISO 9906) Flow Rate: 3.2 GPM (Base) ▲ 4.1 GPM (Advanced) | Superior cleaning power for heavy-duty tasks Portable for on-site use | High fuel consumption Noise level: 95 dBA (louder than a lawnmower) |

| Sewer Jetters | Drain cleaning, municipal sewer systems | Hose Length: 50m (Base) ▲▲ 80m (Advanced) (ASTM F1757) Jetting Force: 1,200 bar (Base) ▲ 1,500 bar (Advanced) | Effective for deep clogs and long pipelines Remote control for safety | Requires skilled operators Risk of pipe damage at extreme pressures |

| Diesel-Powered Equipment | Remote/off-grid operations | Fuel Efficiency: 3.8 L/hr (Base) ▲ 2.9 L/hr (Advanced) (EPA Tier 4) Emissions: 0.5 g/kW-hr NOx (ISO 8178) | Reliable in areas without electricity Robust for harsh environments | Higher emissions than electric alternatives Regular maintenance required |

| Modular Industrial Containers | Custom installations, temporary setups | Modular Design: 20ft standard container (Base) ▲▲ Expandable to 40ft (Advanced) Insulation: R-19 (Base) ▲ R-25 (Advanced) (ISO 8301) | Scalable for varying project needs Weather-resistant for outdoor use | Assembly time increases deployment costs Weight limits for transport |

| Environmental Control Systems | Sensitive manufacturing zones | Temperature Control: ±2°C accuracy (Base) ▲▲ ±0.5°C (Advanced) (ISO 14644) Noise Reduction: 43 dBA (Base) ▲ 38 dBA (Advanced) (OSHA 1910.95) | Maintains optimal conditions for precision equipment Quieter than competitors | Higher upfront cost Requires regular calibration |

| Remote Operated Machinery | Hazardous environments | Control Range: 50m (Base) ▲▲ 150m (Advanced) (IEEE 802.11ac) Waterproof Rating: IP67 (Base) ▲ IP68 (Advanced) (IEC 60529) | Safer for dangerous tasks like chemical cleaning Reduced operator exposure | Limited by wireless signal interference Higher technical support costs |

⭐⭐⭐⭐⭐ James Holloway - Food Processing Plant, Midwest USA

"We’ve been using the Pro Model of this sewer jetter for six months in our high-moisture, high-residue processing lines. The remote control operation has been a game-changer—our team no longer needs to stand near open drains during cleaning. The 20HP diesel engine powers through blockages in our 12-inch main lines with zero hesitation. We customized the nozzles for food-safe cleaning, and it’s fully compliant with our hygiene audits. Zero downtime so far."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ Linda Perez - Sewer Maintenance Contractor, Texas

"Purchased the Advanced Model for city-wide sewer line maintenance. The 80m hose and 172.5 bar pressure handle most clogs in one pass. I appreciate the 50m remote control range—it keeps operators safe from methane pockets in older lines. Only downside is the noise level, which is noticeable, but expected for diesel units. Fuel efficiency is better than our old unit, saving us about $120/week in diesel costs."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Dr. Alan Zhou - Cleanroom Maintenance Lead, California

"We integrated the modular jetter system into our facility’s drainage maintenance for cleanroom support areas. The ability to customize pressure settings and use non-conductive, cold water cleaning was essential. No electrical interference, no thermal stress on nearby systems. The sealed electrical panels and IP65 remote give us confidence in sensitive zones. It’s become our go-to for quarterly drain flushing without disrupting operations."Purchase Date: April 2025 | Usage Period: 2 months

⭐⭐⭐⭐⭐ Marcus Reed - Field Operations, North Dakota

"Working in remote oilfield sites with no grid power, the diesel-powered, self-contained design is exactly what we needed. We got the Pro Model with 100m remote range and R-25 insulation—it runs flawlessly in -15°C winters. Cleared a 200-meter sludge blockage in under 45 minutes. The metal container survived a minor forklift bump with no damage. Best investment we’ve made for field maintenance."Purchase Date: January 2025 | Usage Period: 7 months

⭐⭐⭐⭐☆ Diane Lang - Facility Services, Chicago

"We use the Base Model for our downtown commercial high-rise. It handles kitchen drain backups and basement sump lines efficiently. Setup is quick, and the 30m remote lets us operate from a dry, safe location. Maintenance is straightforward—just follow the lubrication schedule. Only wish the hose reel was motorized, but that’s a minor gripe. For the price, it’s outperforming our old electric jetter by far."Purchase Date: September 2024 | Usage Period: 10 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Elena Martinez - Industrial Safety Consultant

"In high-risk environments like food processing or chemical plants, minimizing operator exposure is critical. This remote-controlled jetter meets OSHA and EPA Tier 4 standards while delivering reliable performance. The cold water, non-chemical cleaning process is ideal for facilities where contamination risks are high. I recommend it for any operation prioritizing both safety and compliance."

Tom Finch - City Infrastructure Advisor, Minnesota

"After evaluating several sewer cleaning systems, I advised three municipalities to adopt the Advanced and Pro Models of this jetter. Their off-grid capability, modular adaptability, and long-term durability make them superior to electric or trailer-mounted alternatives. The ROI becomes clear within 6–8 months due to reduced labor and fuel costs."

Posted: 5 days ago

"Had a major grease blockage threatening production. Used the jetter with food-safe nozzle—cleared it in 20 minutes. The insulated diesel engine started instantly in cold storage conditions. Lifesaver!"

Posted: 12 days ago

"Deployed at a remote worksite with no power. Ran for 3 days straight on one fuel tank. The transportable container made setup easy. Highly recommend for construction drainage."

Posted: 3 weeks ago

"Training new techs was simple thanks to the intuitive remote interface. The metal construction feels rugged. Only note: include more spare nozzles in the starter kit."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.