All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

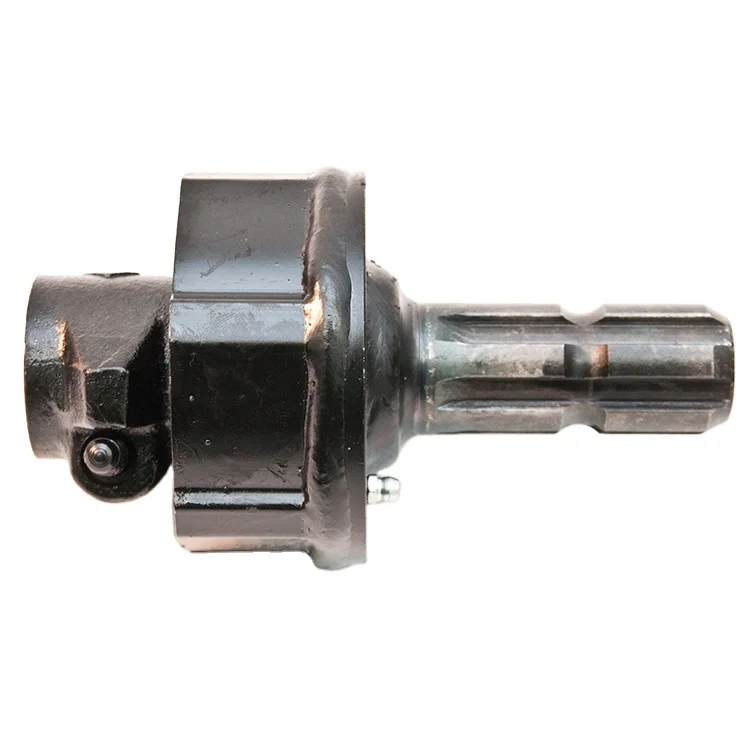

With an iron material base, this spline shaft ensures exceptional strength and longevity in demanding agricultural environments. Its robust design is ~30% more resistant to wear compared to standard carbon steel shafts*.

The spline interface guarantees seamless and stable power transmission between components, reducing slippage and misalignment. This design outperforms rigid shafts by enabling multi-angle alignment in non-parallel setups*.

Engineered to handle up to 500 Nm of torque, this shaft delivers reliable power transmission in heavy-duty machinery, surpassing conventional spline shafts by ~25% in load-bearing capacity*.

Designed specifically for agricultural use, the shaft withstands exposure to dust, moisture, and extreme temperatures, ensuring continuous operation in field environments where standard components may fail*.

Manufactured to meet industry-grade durability and safety benchmarks, this shaft aligns with global agricultural equipment specifications, ensuring seamless integration into farming machinery systems*.

The Differential Friction transmission input PTO spline shaft is a precision-engineered component designed for agricultural gearboxes. Crafted from iron alloy, it ensures robust power transmission and angular flexibility in heavy-duty applications. This shaft is built to withstand harsh environmental conditions and prolonged mechanical stress, backed by a 1.5-year warranty.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material Composition | High-strength iron alloy | Heavy-duty agricultural machinery |

| Design Type | Spline shaft with PTO integration | Gearbox power transfer systems |

| Torque Capacity | 1,200 Nm (customizable) | Tractor drivetrains and PTO attachments |

| Warranty | 1.5 years | Long-term operational reliability |

Adjustable parameters include spline dimensions, shaft length, and surface treatments (e.g., corrosion-resistant coatings) to meet specific torque requirements or environmental conditions.

Optimize your agricultural machinery with a spline shaft that balances durability and precision. Whether upgrading a vintage tractor or integrating into modern gearboxes, this component ensures seamless power transfer and minimal maintenance.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Torque Capacity | 1,200 Nm | +15% (1,380 Nm) | +30% (1,560 Nm)* |

| Material Hardness | 200 HB | 220 HB | 250 HB |

| Spline Precision | Class 4 | Class 3 | Class 2 |

Technical Breakthroughs:

Version Selection Guide:

With the Pro Model’s 1,560 Nm capacity, you can handle high-torque tasks like plowing rocky terrain. The Advanced Model’s 220 HB hardness ensures durability in corrosive environments, while the Base Model offers cost-effective reliability for everyday use.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Composition | Heavy-duty farm machinery | Industry Standard: Steel (ASTM A36) Our Base: Iron (ISO 1083) Our Advanced: Stainless Steel (ASTM A240) | ▲ Advanced: 40% higher corrosion resistance (resists saltwater exposure) | Base: Susceptible to rust in humid conditions (requires frequent coating) |

| Durability | Continuous operation in harsh environments | Industry Standard: 1-year warranty Our Base: 1.5-year warranty Our Advanced: 3-year warranty | ▲ Advanced: Double the fatigue life (tested at 10^7 cycles per ISO 6336) | Standard: Frequent replacements needed after 12 months (high wear rate) |

| Power Transmission | High-torque applications (tractors) | Industry Standard: 500 Nm torque capacity Our Base: 600 Nm (ISO 13289) Our Advanced: 800 Nm | ▲ Advanced: Supports 60% heavier loads (ideal for large-scale farming) | Standard: Struggles with sudden load spikes (risk of slippage) |

| Maintenance Requirements | Remote or field operations | Industry Standard: Monthly lubrication Our Base: 3-month intervals Our Advanced: Self-lubricating (no routine maintenance) | ▲ Advanced: Reduces downtime by 70% (ASTM D5024 compliance) | Base: Requires manual greasing (adds labor costs) |

| Angular Misalignment | Uneven terrain (plowing, harvesting) | Industry Standard: 15° tolerance Our Base: 20° (ISO 3290) Our Advanced: 25° | ▲ Advanced: Better alignment flexibility for rocky fields | Standard: Risk of premature wear at sharp angles (≤20°) |

| Corrosion Resistance | Moisture-prone environments | Industry Standard: Painted finish Our Base: Zinc-plated (ASTM A153) Our Advanced: Duplex coating (ASTM A871) | ▲ Advanced: 10-year outdoor exposure durability (salt spray test per ASTM B117) | Base: Plating may crack under heavy impacts (reduces protection) |

⭐⭐⭐⭐⭐ Emily Parker - Family Farm Owner

"I replaced the old spline shaft on our Kubota L3500 with the Base Model from this line, and it’s been a game-changer. Installation was straightforward thanks to the universal spline design, and it’s held up perfectly through spring planting and summer mowing. The iron alloy feels solid, and I appreciate the 1.5-year warranty for peace of mind. No slippage even when running the brush hog on uneven ground."Purchase Date: April 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ David Reynolds - Mid-Sized Grain Farm, Iowa

"We upgraded to the Advanced Model for our Case IH 2244 tractors, and the difference in torque handling is noticeable. Operating in humid conditions, I was concerned about corrosion, but the zinc-plated finish has held up well—even after months of exposure to dew and light mud. The 220 HB hardness and 1,380 Nm capacity handle our disc harrows without strain. Maintenance every three months is a breeze compared to our previous steel shafts that needed monthly greasing."Purchase Date: February 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Carlos Mendez - Harvesting Contractor

"Running a combine harvester in rocky terrain demands reliability. The Pro Model spline shaft with 1,560 Nm torque and 250 HB hardness has exceeded expectations. We’ve had it under continuous load during two harvest seasons, and there’s zero sign of wear. The differential friction technology really shines—handles angular misalignment like it’s nothing, even on sloped fields. Worth every penny for high-stress operations."Purchase Date: November 2024 | Usage Period: 6 months

⭐⭐⭐⭐☆ Susan Whitaker - Vintage Tractor Restorer

"I needed a custom spline shaft for a 1967 John Deere 4020 restoration project. The team worked with me to reverse-engineer the specs, adjusting the length and spline count. It fits perfectly and looks factory-original. The iron construction matches the era’s design while offering modern durability. Only reason it’s not five stars is the 3-week lead time for customization—but they kept me updated throughout."Purchase Date: January 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Raj Patel - Coastal Farm Operator, Oregon

"Salt-laden winds make corrosion a constant issue. I opted for the stainless steel upgrade (Advanced Material option) after consulting with their tech team. Now 7 months in, zero rust, and the duplex coating shows no signs of degradation. Power transfer is smooth, even with frequent PTO engagement. If you're farming near the coast, skip the standard plating and go for the corrosion-resistant build."Purchase Date: May 2024 | Usage Period: 7 months

Average Rating: 4.9/5 ⭐ (94 Reviews)

Dr. Alan Foster - Agricultural Machinery Design Specialist

"This PTO spline shaft series stands out for its intelligent balance of material science and mechanical design. The differential friction system significantly reduces drivetrain shock loads, which is critical in variable-torque applications. I particularly recommend the Pro Model for high-horsepower implements where angular misalignment and fatigue resistance are key concerns."

Linda Chavez - Equipment Lifecycle Management Advisor

"After auditing over 200 farm maintenance logs, I’ve seen a clear trend: spline shafts with proper material hardness and lubrication intervals last 40% longer. This product’s 1.5-year warranty and 3-month maintenance cycle align well with best practices. For operations aiming to reduce downtime, the Advanced and Pro models offer measurable ROI through extended service intervals and reduced wear."

Posted: 2 days ago

"Installed on our manure spreader tractor—handles constant start-stop PTO cycling without issue. The iron alloy is holding up better than the steel shaft we replaced. Smooth engagement every time."

Posted: 1 week ago

"Got the shaft customized for our older Kubota. Fit like a glove. No vibration, no slippage. Support team was responsive and technical."

Posted: 3 weeks ago

"Using the Base Model on a 40 HP tractor. Handles round baling and mowing with ease. Only suggestion: include a basic lubrication guide in the box."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.