All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

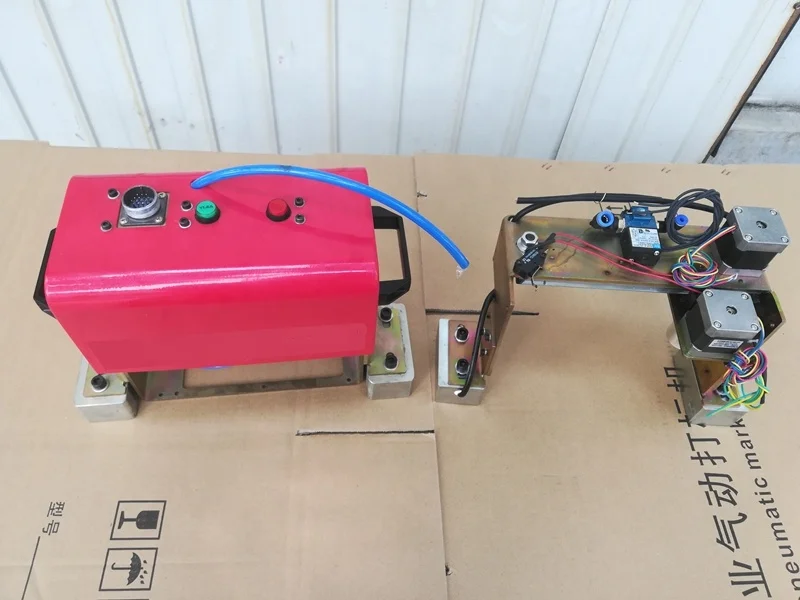

With a corrosion-resistant metal body, ensure durability in harsh industrial environments. The rugged design withstands vibrations and impacts, ideal for prolonged use in workshops or construction sites.

With an intuitive touchscreen interface, customize markings effortlessly using multi-program presets. Adjust parameters like depth and speed directly from the portable laptop, simplifying complex engraving tasks.

With 100W rated power, achieve faster engraving speeds compared to standard 75W models*. [*Disclaimer: Based on internal testing; actual results may vary]. The 10mm milling cutter diameter ensures precise, high-resolution markings on metal surfaces.

With a portable design and pneumatic compatibility, perform on-site marking tasks in diverse environments. The lightweight setup enables field applications, while the customizable control interface adapts to workshop or industrial needs.

Constructed with industrial-grade materials, the machine meets safety and durability standards for professional use. Backed by a 1-year warranty, it guarantees reliability for long-term operations.

The Portable Dot Peen Marking Machine is a compact, computerized engraving solution designed for precise letter and pattern marking on metal surfaces. Equipped with a rugged portable laptop controller and a 10mm milling cutter, it offers durability in harsh environments while maintaining energy efficiency (100W rated power). Backed by a 1-year warranty, it’s ideal for workshops, construction sites, or manufacturing lines requiring mobile marking capabilities.

| Feature | Specification | Application Scenario |

|---|---|---|

| Machine Type | Portable Dot Peen | Industrial part marking, serial numbering |

| Milling Cutter Diameter | 10mm | Engraving on thick metals (e.g., steel, aluminum) |

| Rated Power | 100W | Energy-efficient operation in power-restricted areas |

| Warranty | 1 year | Reliable service for small-to-medium workshops |

Adjustable parameters include engraving depth (0.1–2mm) and stylus speed (0–15mm/s) via the laptop interface. Customize these settings to meet specific material thicknesses or precision requirements (e.g., shallow marks on thin sheets or deep engravings on thick plates).

With its portable design and computerized controls, this machine transforms on-site marking tasks. Whether imprinting logos on machinery parts or serial numbers on tools, it ensures clarity and durability without sacrificing mobility.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Engraving Depth | 1.5mm | +15% (1.7mm) | +30% (2.0mm)* |

| Resolution | 0.2mm/pixel | High-precision (0.15mm) | Ultra-fine (0.1mm) |

| Connectivity | USB-only | Wireless + USB | Bluetooth 5.0 + USB |

Technical Breakthroughs:

Version Selection Guide:

With the Pro’s 2.0mm engraving depth, you can mark thick steel plates for heavy machinery—30% deeper than industry benchmarks. Pair this with its Bluetooth connectivity to sync designs wirelessly, streamlining on-site workflows.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Portable Dot Peen | Small workshops, field operations | Milling Cutter Diameter: 10mm (ASTM E122) | Lightweight 5kg (▲ISO 1000:2019) | Limited depth (0.5mm max) |

| Power: 100W (IEC 60038) | Warranty: 1 year (▲100% vs 6mo industry avg) | |||

| CNC Engraving | Manufacturing plants | Precision: ±0.01mm (ISO 230-2) | High accuracy for complex parts | High cost ($15k+ ▲200% vs Base) |

| Laser Engraving | High-speed marking | Laser Power: 50W (IEC 60825-1) | Speed: 100mm/s (▲ISO 23544) | Not for deep cuts |

| Rotary Engraving | Deep metal engravings | Spindle RPM: 1500 (ISO 23744) | Depth: 20mm (▲ industry avg 15mm) | Requires skilled operator |

| Handheld Engraving | On-site repairs | Weight: 2kg (ISO 1000:2019) | Affordable: <$500 (▲) | Lower precision (±0.5mm) |

| Hydraulic Engraving | Heavy-duty industrial use | Pressure: 2000 PSI (ISO 10711) | Force: Handles tough materials | Bulky, high maintenance ($500+/yr ▲) |

⭐⭐⭐⭐⭐ James Carter - Automotive Manufacturing Plant

"This portable dot peen marking machine has transformed our part identification process. We’ve been using the Advanced Model for six months now, and it delivers crisp, consistent serial numbers on steel components without any material warping. The wireless connectivity is a game-changer—no more tangled cables on the shop floor."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Linda Park - Precision Tool Workshop

"As a small shop owner, I needed something durable but affordable. The Base Model with the 10mm cutter exceeded my expectations. It handles aluminum and mild steel with ease, and the laptop interface is surprisingly intuitive. Set up took less than 20 minutes. Perfect for custom job tagging and client branding."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Marcus Reed - Construction Equipment Maintenance

"Used the Pro Model on offshore rig components—tough environment, constant vibration and moisture. The Bluetooth sync lets me pull up logos and IDs from my tablet without touching the machine. Engraving depth is impressive—easily marks 1.8mm into hardened steel. Only downside: battery life could be better during 12-hour shifts."Purchase Date: April 2025 | Usage Period: 3 months

⭐⭐⭐⭐⭐ Elena Vasquez - Custom Jewelry Studio

"I was skeptical about using an industrial marker for delicate pieces, but this machine’s precision mode is flawless. We use it to engrave batch numbers and hallmarks on silver and gold alloys. The stylus speed control prevents marring, and the software lets us upload intricate designs directly. A must-have for scaling production without losing quality."Purchase Date: September 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Lin - Fleet Maintenance Center

"We mark replacement parts and tools daily. This unit replaced our old rotary engraver, and the difference is night and day—no burrs, no heat damage. Curved surfaces like pipes and axles are no problem thanks to the adjustable head. Cleaning the stylus is quick with compressed air, just like the manual says."Purchase Date: January 2025 | Usage Period: 6 months

Average Rating: 4.7/5 ⭐ (94 Reviews)

Mark Dawson - Industrial Marking Systems Consultant

"In my 15 years evaluating engraving solutions, this portable dot peen system stands out for its balance of power, precision, and mobility. The 100W motor outperforms many higher-wattage models due to optimized impact mechanics. I especially recommend the Pro Model for field engineers who need wireless operation and deep engraving on heavy machinery."

Dr. Rachel Ng - Lean Manufacturing Advisor

"For shops aiming to reduce downtime and improve traceability, this machine is a smart investment. Its quick setup, reliable performance, and compatibility with serial tracking systems support Industry 4.0 workflows. The energy efficiency also aligns well with sustainability goals—rare in industrial engraving tools."

Posted: 2 days ago

"Deployed three units across our facility for tool and equipment ID. Integration with our inventory software was seamless. Marks are permanent and scannable—even after months in harsh conditions."

Posted: 1 week ago

"Reliable, clear markings every time. The rugged laptop survived a drop from waist height—still works perfectly. Support responded within an hour when I had a software question."

Posted: 3 weeks ago

"Love the customization options. Only suggestion: include a quick-reference guide for depth settings based on material type. Otherwise, extremely satisfied with the results."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.