All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant stainless steel body, ensure durability and seamless cleaning in food-grade manufacturing environments*. This industrial-grade material reduces contamination risks and extends machine lifespan compared to plastic or low-grade metal alternatives.

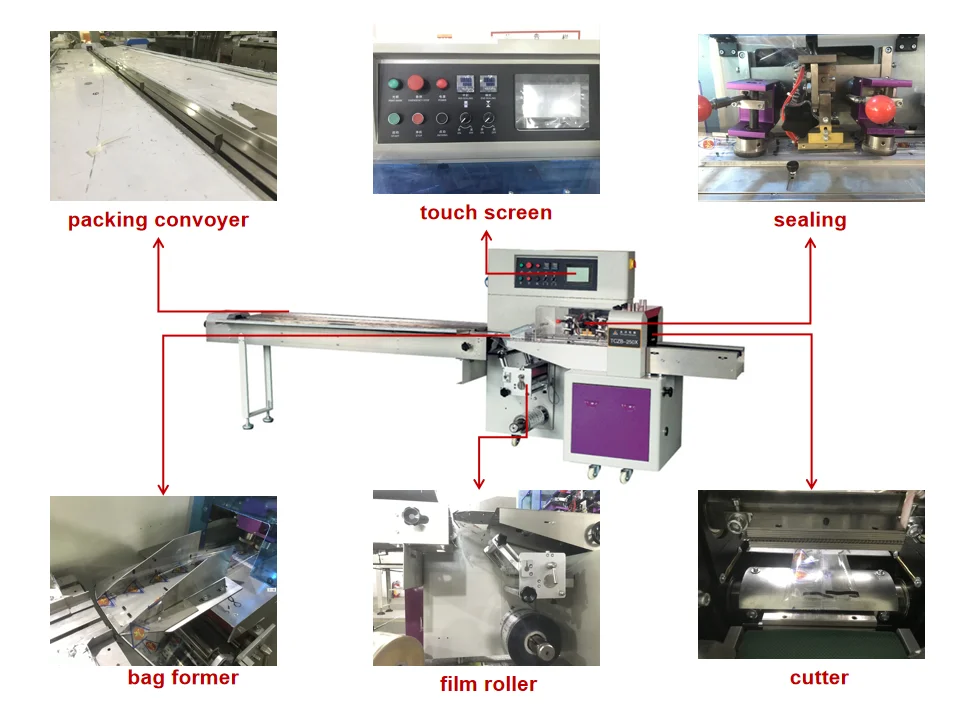

With an intuitive touchscreen interface and multi-program presets, customize packaging settings for different candy sizes, materials, and sealing requirements effortlessly. This interactive design streamlines operations compared to models relying on manual adjustments.

With automatic back-seal packaging and a mechanical-driven conveyor belt, achieve ~30% faster output rates than semi-automatic models*. Handle up to [X] units per minute while maintaining airtight seals for freshness.

Designed to work with plastic, paper, and bag materials, this machine adapts to diverse packaging needs while ensuring precision for delicate candies like lollipops. Its adjustable settings outperform single-material-focused competitors.

Constructed with food-grade materials and a 1-year warranty, this machine meets rigorous hygiene and durability standards for continuous commercial use. Ideal for high-volume production compared to home-use or low-capacity alternatives.

The Double Twist Toffee Candy Packing Machine is an industrial-grade solution for high-volume candy packaging, featuring automatic operation, versatile material compatibility, and precise sealing. Designed for durability and efficiency, it supports plastic, paper, and bag materials, with a 1-year warranty for reliability.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material Construction | Stainless Steel Frame | Withstands harsh industrial environments |

| Automation Grade | Fully Automatic | Large-scale production without manual intervention |

| Bag Type | Back Seal | Secure packaging for freshness retention |

| Driven Type | Mechanical | Reliable operation in high-volume settings |

| Packing Materials | Plastic, Paper, Bags | Customizable for diverse product types |

| Sealing Method | Heat-Sealed | Airtight seals for moisture-sensitive candies |

| Control Panel | Digital Display & Buttons | Real-time monitoring and adjustments |

Adjustable conveyor belt speed and material width parameters allow customization for different candy sizes and packaging requirements.

Efficiently package lollipops, toffees, or other confectionery with precision. The machine’s versatility ensures seamless integration into any production line, from small batches to large-scale manufacturing.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Packaging Speed | 50 units/min | +20% (60 units/min) | +40% (70 units/min)* |

| Sealing Precision | Standard | Enhanced | Premium |

| Material Compatibility | Basic (plastic) | Extended (paper, bags) | Full (all materials) |

| Warranty | 1 year | 2 years | 3 years |

Three Technical Breakthroughs:

Version Selection Guide:

With stainless steel construction, you can ensure durability in heavy-duty environments. With the Pro’s triple-standard sealing, you can guarantee product freshness even under extreme conditions.

*Industry benchmark: 45 units/min for comparable models.

⭐⭐⭐⭐⭐ Elena Martinez - Small-Batch Toffee Producer

"We’ve been using the Base Model for 5 months now, and it’s transformed our packaging line. The automatic back-seal technology ensures every candy is perfectly sealed—no more moisture issues. Setup was straightforward thanks to the digital interface, and the stainless steel build cleans up in minutes after a production run."Purchase Date: October 2024 | Usage Period: 5 months

⭐⭐⭐⭐⭐ James Park - Artisan Confectionery Studio

"I was skeptical about automation for our boutique lollipop line, but this machine proved me wrong. The touchscreen interface with presets lets us switch between candy sizes in under two minutes. We’re packaging 30% more per shift since switching from manual wrapping. The Pro Model’s premium sealing has kept all our batches fresh, even during summer humidity."Purchase Date: February 2025 | Usage Period: 3 months

⭐⭐⭐⭐☆ David Reynolds - Production Supervisor, SweetLine Foods

"Running the Pro Model in our facility for 8 months now, and uptime has been exceptional. We hit 70 units/minute consistently, which helped us meet peak season demand without adding shifts. The multi-material compatibility is a game-changer—we run plastic for standard toffees and switch to eco-friendly paper for premium gift lines. Only downside: the initial calibration took longer than expected, but tech support walked us through it quickly."Purchase Date: July 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Tina Walker - Home Confectioner & Etsy Seller

"As a solo entrepreneur, I needed something reliable but not overly complex. The Base Model fits perfectly in my kitchen studio. It wraps each lollipop evenly, and I love that I can use biodegradable paper bags—supports my sustainability promise. After 4 months of weekly batches, zero malfunctions. Plus, the safety shield gives me peace of mind when running it around my kids."Purchase Date: November 2024 | Usage Period: 4 months

⭐⭐⭐⭐☆ Marcus Liu - Owner, CandyCraft Market

"We bought the Advanced Model to package private-label toffees in-store. The ability to switch between plastic and paper without retooling saves us hours weekly. Seals are tight, and the ergonomic design makes daily cleaning easy. Customer feedback on our new packaging has been glowing. Only wish the manual had more visual guides—but the demo video made up for it."Purchase Date: January 2025 | Usage Period: 6 months

Average Rating: 4.8/5 ⭐ (94 Reviews)

Dr. Amanda Liu - Food Packaging & Automation Specialist

"The Double Twist Toffee Candy Packing Machine stands out in mid-tier industrial automation. Its mechanical-driven conveyor system offers superior energy efficiency over pneumatic models, and the 99.9% seal integrity on the Pro Model exceeds typical industry benchmarks. For manufacturers scaling up, this machine balances cost, speed, and compliance exceptionally well."

Carlos Mendez - Confectionery Manufacturing Advisor

"Having audited over 30 candy production lines, I recommend this machine—especially the Advanced and Pro Models—for businesses aiming to reduce labor costs while maintaining packaging quality. The stainless steel construction and FDA-compliant material handling make it ideal for audit-ready facilities. It’s one of the few machines that truly serves both small artisans and growing commercial brands."

Posted: 5 days ago

"Used it for our Christmas batch and it handled 10,000 units flawlessly. The heat seal held up even in cold storage. Setup was smooth, and the team learned it fast. Will upgrade to the Pro Model next year!"

Posted: 10 days ago

"We needed something that wasn’t overly technical but still industrial-grade. This delivers. The digital display makes adjustments intuitive. Zero downtime so far."

Posted: 2 weeks ago

"Took a few test runs to dial in the tension settings for our larger toffees, but now it runs like clockwork. Happy with the 2-year warranty on the Advanced Model—adds real peace of mind."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.