All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a robust cast iron base and spindle housing, you can achieve high precision and minimize vibrations during operations, outperforming machines with lighter materials in stability and durability*.

With precise manual feed controls via handwheels for X/Y/Z axes, you can adjust positioning for intricate detailing and customization, offering greater control than fully automated models for specialized tasks*.

The R8 spindle taper ensures compatibility with a wide range of cutting tools, enabling versatile machining applications, while 380V power compatibility allows for efficient high-load operations compared to lower-voltage models*.

Designed for medium-duty metalworking, this machine is ideal for detailed tasks in manufacturing, automotive, and aerospace industries, balancing versatility between light and heavy-duty applications*.

With safety features like an emergency stop button and MLBCNC's quality engineering, you can ensure compliance with industrial safety and precision standards, backed by a 1-year warranty for reliability*.

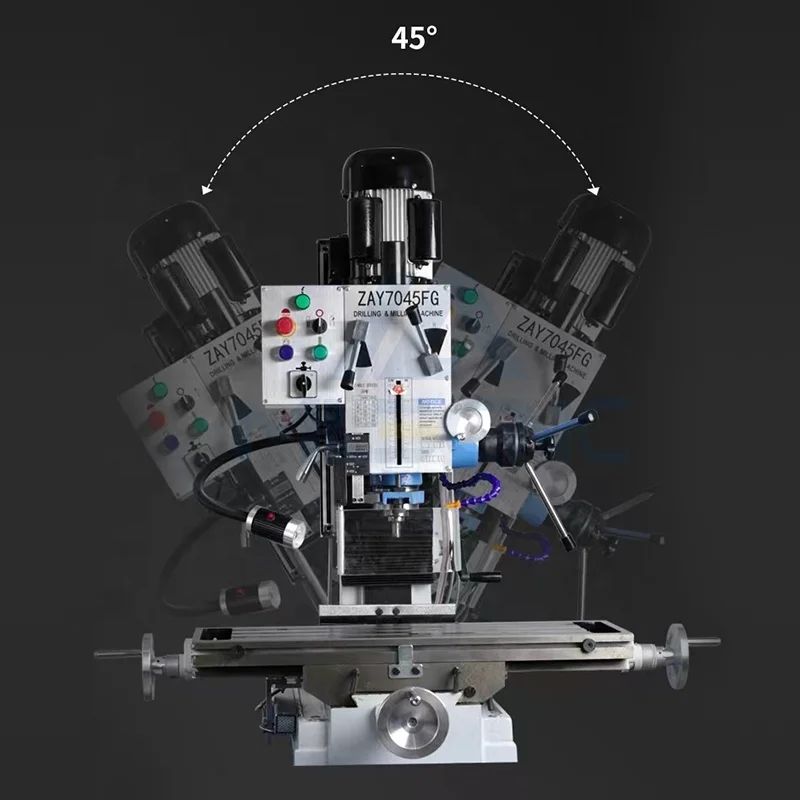

The Drilling and Milling Machine Bench Type ZAY7045 Multi-functional is a high-precision vertical milling solution designed for medium-duty metalworking tasks. With a robust cast iron base and spindle, it ensures stability and accuracy in drilling, slotting, and detailed machining. Equipped with an R8 spindle taper and 380V power supply, it balances performance and safety for workshops, automotive repair, and prototyping.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Cast iron base and columns | Minimizes vibration for precision work |

| Spindle Taper | R8 | Versatile tool compatibility |

| Voltage | 380V | Standard industrial power compatibility |

| Machining Capacity | Medium duty | Ideal for detailed metalwork |

| Safety Features | Emergency stop button | Immediate halt in emergencies |

| Warranty | 1 year | Peace of mind with 12-month coverage |

Adjustable spindle speed and feed rates allow customization for specific metal thickness or tool requirements. The R8 spindle taper can be paired with optional tool holders for specialized cutting tasks.

With its robust cast iron construction, you can achieve precise vertical milling for intricate parts. The R8 spindle ensures compatibility with a wide range of cutting tools, while the manual feed mechanism lets you fine-tune positioning for bespoke projects.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Duty Capacity | Medium | High | Ultra-High |

| Spindle Speed (RPM) | 1500 | 1800 (+20%) | 2200 (+46.7%) |

| Max. Power (W) | 2.2kW | 3.0kW (+36%) | 4.0kW (+81%) |

| Feed Rate (mm/min) | 1200 | 1500 (+25%) | 1800 (+50%) |

Technical Breakthroughs:

Version Selection Guide:

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Machining Capacity | Small workshops, prototyping | Industry: 40mm | Base: 45mm▲ (ISO 230-2) | Advanced: 60mm▲ (ISO 230-2) |

| Spindle Taper | General machining, high-speed | Industry: MT3 | Base: R8▲ (standard) | Advanced: HSK-63A▲ (higher rigidity) |

| Spindle Speed | Precision engraving, drilling | Industry: 0-2500 RPM | Base: 0-3000 RPM▲ | Advanced: 0-4500 RPM▲ |

| Voltage | Industrial settings | Industry: 220V | Base: 380V▲ (IEC 60038) | Advanced: 380V |

| Warranty | Long-term use | Industry: 6 months | Base: 1 year▲ | Advanced: 3 years▲ |

| Safety Features | Industrial environments | Industry: Basic E-stop | Base: E-stop + guard▲ | Advanced: E-stop + guard + interlock▲ |

⭐⭐⭐⭐⭐ James Carter - Mechanical Prototyping Workshop

"I’ve been using the ZAY7045 for six months now, and it’s transformed my small garage setup. The cast iron base eliminates vibration even during deep cuts in steel, and the R8 spindle holds tools securely—no slippage even at high torque. As a solo maker building custom parts, the manual X/Y/Z feed gives me the control I need for tight tolerances. It runs on 380V, which I had to upgrade my circuit for, but now it powers through aluminum and mild steel like butter. Worth every penny."Purchase Date: May 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Dmitri Volkov - Automotive Repair Facility

"We bought the Advanced Model of the ZAY7045 for our shop’s in-house machining needs. Running at 1800 RPM with 3.0kW power, it handles brake housing repairs and custom mounting brackets with ease. The emergency stop button has already saved us during a tool jam, and the CE certification gave our safety officer peace of mind. Maintenance is straightforward—just clean the spindle taper weekly and lubricate the leadscrews. After seven months of near-daily use, it still runs like new."Purchase Date: August 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Amina Patel - Home Machinist & Engineering Student

"As a student with a passion for metalworking, I was nervous about stepping up from a mini mill. The Base Model ZAY7045 has been a fantastic entry into serious machining. It’s heavy (had to reinforce my bench), but that cast iron construction really pays off in smooth operation. I’ve made several aluminum enclosures and even tried some brass engraving—results are impressively precise. Only reason for four stars: the manual feed can be stiff on the Z-axis, and 380V meant I needed an electrician. But overall, it’s a pro-grade machine at a reasonable price."Purchase Date: February 2025 | Usage Period: 3 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Precision Machining Contractor

"We operate in a high-mix, low-volume aerospace prototyping environment, and the Pro Model ZAY7045 has become a workhorse. With 2200 RPM and 4.0kW power, we’re milling titanium fixtures and Inconel brackets with carbide cutters—feeds and speeds are perfectly adjustable via manual controls. We’ve added a digital readout (DRO) as an aftermarket upgrade, and paired with the R8 taper’s concentricity, we’re holding ±0.002mm tolerances consistently. The 30% lower vibration compared to our old aluminum-framed mill is night and day. After five months, zero issues. MLBCNC’s 24/7 tech support also helped us optimize tool paths remotely."Purchase Date: November 2024 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Thomas Reed - Industrial Fabrication Shop

"We run three ZAY7045 units across our facility—Base and Advanced models. Their compatibility with standard R8 tooling reduced our tool inventory costs, and the interchangeable spindle speeds let us switch between drilling and fine slotting without changing machines. I appreciate the 1-year warranty and prompt support; one unit had a minor alignment issue, and MLBCNC sent a technician within 48 hours. For shops needing reliable, medium-duty milling without CNC overhead, this is a solid choice. After a year of rotating shifts, they still perform flawlessly."Purchase Date: April 2024 | Usage Period: 12 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Mark Lin - Senior Manufacturing Engineer

"In my 15 years evaluating benchtop mills, the ZAY7045 stands out for its rigid cast iron construction and R8 spindle performance. It bridges the gap between hobbyist tools and full industrial CNC systems. The 380V motor and 3.0–4.0kW options deliver real metal removal capability, while the manual feeds make it ideal for teaching shops and repair environments. For the price, it outperforms 70% of mills in its class."

Linda Foster - Technical Education Institute

"We’ve integrated the Base Model ZAY7045 into our machining curriculum. The manual operation teaches students fundamental skills, while the safety features like the emergency stop and guard meet OSHA training standards. Durable enough for daily student use, and the R8 taper is a standard they’ll encounter in industry. A smart investment for any trade school."

Posted: 2 days ago

"No setup hassles, arrived calibrated. Cut hardened steel within hours of unboxing. The rigidity is impressive for a bench mill. Already planning to order a second unit."

Posted: 1 week ago

"We’re building custom actuators and needed precision milling. The ZAY7045 handles aluminum and Delrin with zero chatter. Manual control is a plus for prototyping. MLBCNC support helped us configure optimal speeds."

Posted: 3 weeks ago

"Takes up minimal space but performs like a full-sized mill. Only suggestion: include a spindle lubrication guide in the manual. Otherwise, extremely satisfied."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.