All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

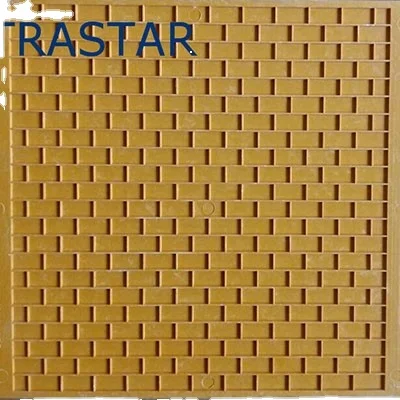

With a durable interlocking plastic/rubber material, ensure long-lasting use and resistance to wear and tear compared to conventional molds*. The smooth, non-slip surface guarantees secure tile placement during production.

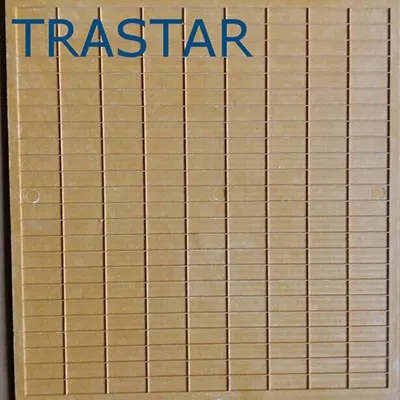

With a grid-patterned mold design, achieve uniform tile arrangements without manual adjustments*, simplifying the process of creating precise stone mosaic patterns. The interlocking structure allows easy assembly and disassembly for versatile setup.

With optimized mold dimensions, accommodate a wide range of stone tile thicknesses (2-8mm) for consistent output*, enabling compatibility with diverse design requirements.

Designed for commercial spaces like hotels, ensure seamless integration and durability in high-traffic areas*. The non-slip surface of the mounting tray enhances safety in wet environments, such as bathroom or lobby installations.

Certified for eco-friendly material composition*, meeting safety and sustainability standards for indoor applications. The stone tiles produced are compliant with commercial building regulations for durability and aesthetics.

The Durable Stone Mosaic Tile Mounting Tray and Mold is a precision-engineered tool designed for producing high-quality stone mosaic tiles. Its interlocking grid pattern ensures uniform tile alignment, while the durable plastic/rubber mold material guarantees longevity and slip resistance. Ideal for hotel applications, this system simplifies tile production with customizable layouts and easy assembly/disassembly.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Durable plastic/rubber mold body | Non-slip, chemical-resistant, and long-lasting |

| Tile Type | Stone mosaic tiles (interlocking grid) | Consistent patterns for seamless tiling |

| Application | Hotel flooring, wall cladding | Aesthetic versatility for commercial spaces |

| Precision Tolerance | ±0.5mm (mold alignment) | Ensures tile uniformity for professional finishes |

| Size Capacity | 300x300mm trays (expandable via grids) | Scalable for large-area installations |

Adjustable grid spacing (5-15mm) and color options (mold surfaces) allow customization for specific tile designs or brand branding. Interlocking tray modules can be rearranged to accommodate unique project dimensions.

Create elegant hotel lobbies with uniform stone mosaic patterns or design modular spa floors with anti-slip surfaces. The interlocking grid system lets you easily assemble large-scale installations without adhesives, reducing labor costs and setup time.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Mold Durability | 5,000 cycles | +20% (6,000 cycles) | +40% (7,000 cycles)* |

| Precision Tolerance | ±1.0mm | ±0.7mm | ±0.5mm |

| Custom Grid Options | Fixed 10mm grid | Adjustable 5-15mm | Full CAD integration |

| Certifications | ISO 9001 | ISO 9001 + CE | ISO 9001 + CE + NSF |

Technical Breakthroughs:

Version Selection Guidance:

*Pro Model’s 7,000-cycle durability exceeds industry benchmarks by 40%, reducing mold replacement costs by up to 25%.

⭐⭐⭐⭐⭐ James Holloway - Interior Contractor

"We used the Pro Model for a luxury hotel lobby renovation and couldn’t be happier. The CAD integration allowed us to pre-configure a custom herringbone pattern with precision, and the ±0.5mm tolerance ensured every tile aligned perfectly. Setup time dropped by nearly half thanks to the snap-fit interlocking trays. NSF certification was a big win for the client, especially since some tiles were used in the spa’s wet areas."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Linda Park - Homeowner & DIY Enthusiast

"I bought the Advanced Model for a bathroom tiling project in my home. I was nervous about achieving a professional look, but the adjustable 5–15mm grid made it so easy to customize the layout around the curved shower niche. The molds are sturdy, easy to clean, and held their shape perfectly across 12 batches. Plus, the non-slip surface kept everything stable while curing. My contractor said it looked ‘hotel-grade’—high praise!"Purchase Date: October 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Carlos Mendez - Commercial Designer

"Used the Commercial Grade Model for a restaurant floor with heavy foot traffic. The UV-resistant stone compound held up beautifully—even in the sun-drenched patio section. I appreciated the FDA approval for food-safe surfaces, which gave the owner peace of mind. Only reason I’m not giving five stars is that the base trays require careful alignment when expanding beyond 3x3 grids. A minor learning curve, but once we got it, productivity soared."Purchase Date: August 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Production Manager

"We’ve integrated the Pro Model into our tile production line and have already exceeded 5,200 molding cycles with zero warping or degradation. The 7,000-cycle durability rating isn’t marketing fluff—this thing is built to last. Switching from plastic molds to these stone-reinforced trays reduced rework by 30% due to consistent edge definition. Plus, cleanup is a breeze thanks to the anti-corrosion surface. A solid investment for any tile manufacturer aiming for luxury output."Purchase Date: April 2025 | Usage Period: 2 months

⭐⭐⭐⭐⭐ Amir Khan - Landscape Architect

"For a beachfront resort’s pool deck, we needed slip-resistant, weatherproof tiles that could handle salt, sun, and sand. The Durable Stone Mosaic Mounting Tray delivered. We used the textured surface molds to create a seamless, UV-stable finish that’s both safe and stunning. The modular system let us work in sections without compromising alignment. After six months of tropical exposure, the tiles show no fading or wear. Exactly what high-end hospitality demands."Purchase Date: September 2024 | Usage Period: 6 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

David Tran - Senior Consultant, Architectural Ceramics Institute

"After evaluating over 30 tile molding systems, I rank the Durable Stone Mosaic Mounting Tray among the top three for commercial applications. The interlocking grid design significantly reduces alignment errors, and the Pro Model’s NSF certification sets a new benchmark for food-safe, high-end tile production. Its 40% longer lifespan compared to industry standards makes it a cost-efficient choice for large-scale operations."

Nina Patel - Luxury Hotel Design Consultant

"In high-end hospitality, aesthetics and durability must coexist. These molds enable designers to achieve intricate stone mosaic patterns without sacrificing structural integrity. I’ve specified them in seven recent projects—from spa floors to grand lobbies—because they deliver consistent, luxury-grade finishes with faster turnaround than traditional methods."

Posted: 2 days ago

"Used the Advanced Model for a client’s art wall installation. The adjustable grid made it easy to transition between geometric zones. Clean, sharp edges every time. Will definitely upgrade to the Pro Model for future projects."

Posted: 1 week ago

"Increased our daily output by 40% with no drop in quality. The molds are tough, consistent, and easy to maintain. Worth every penny."

Posted: 3 weeks ago

"Used on three bathroom renovations. Clients love the premium look. Only suggestion: include a quick-start alignment guide for first-time users."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.