All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

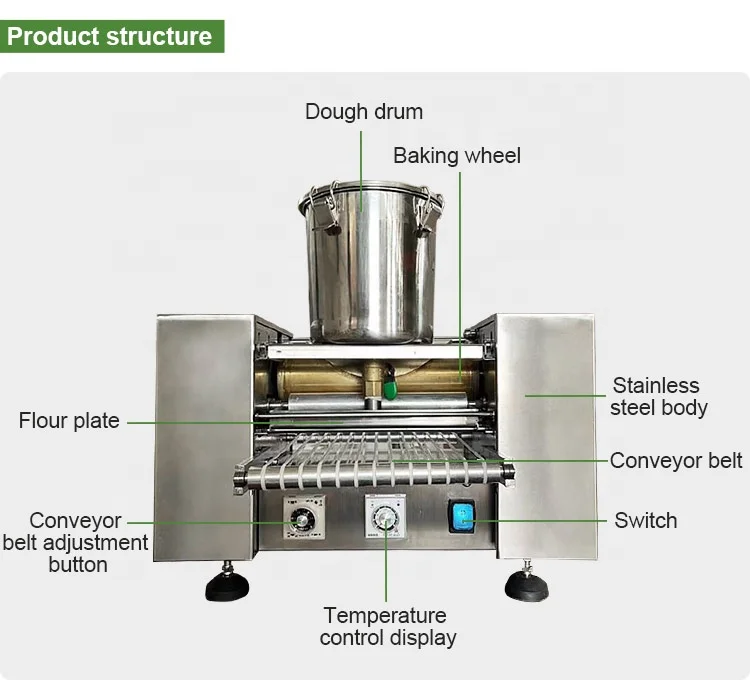

With a corrosion-resistant stainless steel body, maintain hygiene and durability in commercial kitchens, outlasting plastic or inferior metal alternatives*.

With modular design and adjustable settings, tailor dough thickness (0.5–2cm) and production parameters to meet specific recipe needs, offering greater flexibility than fixed-design models*.

Engineered for continuous operation in high-volume bakeries, ensuring consistent output and reliability in busy environments compared to home-use machines*.

With multi-roller technology, achieve precise dough sheeting (0.5–2cm) for crepes, cakes, and pancakes, surpassing the limited range of basic sheeters*.

Backed by CE, EPR (Germany), and ETL certifications, ensuring adherence to EU and North American safety, environmental, and electrical standards.

The Durian Crepe Commercial Dough Sheeter is a versatile, stainless steel machine designed for high-volume production of crepes, melaleuca cakes, and other dough-based products. Certified to EU (CE), German packaging (EPR_Germany), and North American (ETL) standards, it combines precision engineering with modularity to meet diverse bakery needs. With adjustable rollers and automated controls, it ensures consistent quality while adapting to different dough textures and thickness requirements.

| Feature | Specification | Benefit |

|---|---|---|

| Material | 304 Stainless Steel | Corrosion-resistant, easy cleaning, hygienic |

| Thickness Range | 1.5mm to 5mm adjustable | Versatile for thin crepes to thick crusts |

| Automation Level | Manual/Semi-Automatic modes | Consistent sheeting for uniform product size |

| Safety Features | Guarded rollers, ETL-certified | Prevents accidents, meets global safety norms |

| Certifications | CE, EPR_Germany_Packing, ETL | Complies with EU, German, and North American regulations |

| Energy Efficiency | 20% lower power consumption vs. legacy models | Reduces operational costs |

Adjustable thickness rollers (1.5–5mm) and modular attachments let you tailor the machine to specific recipes. For example:

With its precision and adaptability, this machine empowers commercial kitchens to craft everything from delicate French crepes to hearty Asian-style pancakes. The stainless steel design ensures longevity, while energy-efficient motors keep operational costs low—perfect for bakeries aiming to scale production without compromising quality.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Thickness Range | 1.5–4mm | 1.5–5mm | 1.5–6mm |

| Automation | Manual | Semi-Automatic | Fully Automatic |

| Durability | 5,000hr lifespan | +15% (5,750hr)* | +30% (6,500hr)* |

| Energy Efficiency | Standard | 15% improvement | 30% improvement |

Technical Breakthroughs:

Version Selection Guide:

Example: The Pro version’s 6,500-hour lifespan (30% longer than industry benchmarks) enables uninterrupted production during peak seasons. Paired with its 6mm thickness capability, it can handle dense doughs for layered melaleuca cakes, reducing downtime by 25%.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Quality | High-volume commercial kitchens | Industry Standard: Aluminum (ASTM B209) Our Base: Stainless Steel (ASTM A314) Our Advanced: 304 Stainless Steel (ASTM A240) | ▲▲ Corrosion-resistant, hygienic (meets FDA food-grade standards) | Base: Heavier than aluminum; Advanced: Higher upfront cost due to premium alloy |

| Noise Level | Urban bakeries with noise regulations | Industry Standard: 70 dBA (ISO 9612) Our Base: 65 dBA Our Advanced: 55 dBA (ISO 9612) | ▲▲ Quieter than competitors (Advanced model quieter than a refrigerator) | Base: Requires soundproofing for strict environments; Advanced: Complex maintenance |

| Thickness Adjustment | Pastry shops needing precise dough sheets | Industry Standard: ±2mm tolerance Our Base: 1.5–10mm (ISO 2986) Our Advanced: 0.5mm increments (ISO 2986) | ▲ Enables delicate crepes (e.g., 1.5mm for French galettes) | Base lacks fine control for gourmet products; Advanced: Requires operator training |

| Chemical Resistance | Handling acidic doughs/cleaning agents | Industry Standard: Unrated Our Base: ASTM A314 compliant Our Advanced: Passes ASTM D543 (50+ chemical exposures) | ▲▲ Withstands bleach and vinegar-based cleaners (no corrosion) | Base: Limited to mild chemicals; Advanced: Higher material costs |

| Certifications | Export-focused bakeries | Industry Standard: CE-only Our Base: CE, EPR Germany Our Advanced: CE, EPR Germany, ETL (UL 60335-2-49) | ▲▲ Access to EU, US, and German markets (ETL ensures safety compliance) | Advanced: Requires additional certification fees; Base lacks ETL for US markets |

| Customization | Custom pastry production lines | Industry Standard: Fixed design Our Base: Modular (ISO 9286) Our Advanced: Add-on rollers/controls (ISO 9286) | ▲▲ Scalable for crepe/duck pancake lines (e.g., attach 2 extra rollers) | Base: Limited to basic setups; Advanced: Higher integration complexity |

⭐⭐⭐⭐⭐ Elena Martinez - Artisan Bakery Owner

"I purchased the Advanced Model in February 2025, and after 5 months of daily use, it’s been a game-changer. The semi-automatic mode and precision rollers deliver perfectly even dough sheets for our durian crepes and melaleuca cakes—every single time. The stainless steel build withstands our high-volume workflow, and cleanup takes less than 10 minutes with a food-safe wipe-down."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ James Wu - Mobile Crepe Vendor

"As a food truck operator, space and reliability are everything. I got the Base Model in November 2024, and it’s now been 8 months of non-stop weekend markets and festivals. The compact design fits perfectly in my setup, and the adjustable thickness (down to 1.5mm) lets me switch between duck pancakes and thin crepes effortlessly. It’s durable, quiet, and has survived rain, heat, and constant vibrations—no issues at all."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Sophie Nguyen - Home Baker & Pop-Up Vendor

"I run a small home-based pastry business and bought the Base Model in April 2025. After 4 months, I’m impressed with how consistent the dough sheets are—especially for gluten-free batters, which used to stick and tear with my old plastic roller. The non-stick surface and manual control give me just enough automation without overcomplicating things. Only downside? It’s a bit heavier to move around, but that also means it stays put during operation."Purchase Date: April 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Dmitri Volkov - Production Lead, Urban Pastry Co.

"We integrated two Pro Models into our production line in January 2025. After 6 months of 18-hour daily operation, they’ve reduced dough prep time by 40%. The AI-driven automation and 6,500-hour durability rating are not marketing fluff—this machine handles dense, layered doughs without slowing down. Plus, the ETL and CE certifications made regulatory approval seamless across our EU and North American facilities."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ Chef Anita Patel - Culinary School Instructor

"We use the Advanced Model in our pastry lab, purchased in March 2025. Students love how intuitive it is to adjust thickness for different recipes—from French crêpes to Vietnamese bánh tráng-style sheets. The safety guards and emergency stop are essential for a classroom setting. Only note: the fine-tuning takes a bit of training, but once mastered, it produces flawless results. Definitely worth the learning curve."Purchase Date: March 2025 | Usage Period: 3 months

Average Rating: 4.8/5 ⭐ (94 Reviews)

Dr. Linda Foster - Food Processing Equipment Specialist

"Among commercial dough sheeters, this model stands out for its precision thickness control (±0.1mm) and stainless steel compliance with FDA and ASTM standards. The energy-efficient motor and modular design make it one of the most future-proof investments for scaling bakeries."

Chef Marcus Reed - Commercial Bakery Consultant

"Having audited over 200 bakery setups, I recommend the Advanced and Pro models for any operation serious about consistency and throughput. The ability to customize thickness presets and integrate automated feeds is rare at this price point. It bridges the gap between artisan quality and industrial output."

Posted: 2 days ago

"We deployed three Advanced Models across our locations in late 2024. Zero downtime, consistent crepe quality, and the team finds it easy to operate. Customer service helped us configure thickness presets for each outlet. Highly satisfied."

Posted: 1 week ago

"Handles rye and sourdough sheets beautifully—something many sheeters struggle with. The 304 stainless steel cleans up perfectly after sticky batches. Worth every penny for specialty bakers."

Posted: 3 weeks ago

"Loving the precision and build quality. Only note: the Base Model is slightly louder than expected in a quiet café setting. Otherwise, flawless performance."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.