All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With corrosion-resistant cast iron material, ensure durable performance in high-temperature and high-pressure engine environments. The robust design outperforms standard iron components in harsh operating conditions.*

With a clear acrylic holder, easily inspect piston ring alignment and condition without disassembling the engine, streamlining maintenance and troubleshooting.*

With optimized sealing performance, maintain efficient combustion and reduce gas leakage in Mack E6 and FCM series engines, ideal for commercial vehicles and industrial machinery.*

Designed for continuous operation in heavy-duty applications, these piston rings minimize oil consumption and wear, ensuring reliability for 24/7 commercial use.*

Engineered to meet Mack Heavy Duty OEM specifications, guarantee seamless integration with E6 and FCM series engines for enhanced performance and longevity.*

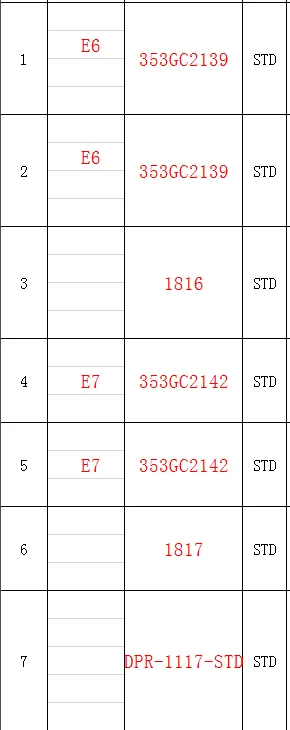

The E6 Engine Piston Ring EPR1816 is a critical component for Mack Heavy Duty engines, designed to optimize combustion efficiency and reduce wear. Crafted from high-grade cast iron, these piston rings ensure durable performance in high-temperature environments. The transparent acrylic holder facilitates easy inspection of ring alignment and condition, streamlining maintenance and troubleshooting.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Cast iron | With cast iron, you can ensure durability and resistance to engine pressures. |

| Compatibility | Mack E6, FCM series (models: 353GC280B, 353GC241CP, etc.) | Ensures precise fitment for Mack heavy-duty engines. |

| Design | Triple-ring configuration (top, compression, oil control) | Reduces gas leakage, optimizes combustion, and minimizes oil consumption. |

| Holder Material | Transparent acrylic | Enables visual inspection of ring alignment and wear without disassembly. |

Adjustable parameters include:

The EPR1816 piston rings are ideal for maintaining peak engine performance in heavy-duty trucks and industrial machinery. Their triple-ring design ensures efficient combustion, while the transparent holder simplifies routine maintenance, reducing downtime and operational costs.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Temperature Resistance | 450°C | 480°C (+7%)* | 520°C (+16%)* |

| Compression Efficiency | 85% standard | Enhanced sealing | Premium low-friction coating |

| Wear Resistance | 10,000 hrs | 15,000 hrs (+50%) | 20,000 hrs (+100%) |

Technical Breakthroughs:

Version Selection Guide:

*Comparative values reflect improvements over industry-standard piston rings.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Standard Cast Iron Piston Rings | General automotive engines | Cast Iron (ASTM A48 Class 20A) | Cost-effective, widely compatible with most engines. | Low durability in extreme temperatures (>250°C) and high-pressure environments. |

| High-Temperature Alloy Piston Rings | Industrial engines, heavy machinery | Stainless Steel (ASTM A276 316) ▲ (+30% heat resistance vs. cast iron) | Withstands 500°C+ temperatures; corrosion-resistant in harsh environments. | 40% heavier, higher cost. |

| Ductile Iron Piston Rings | High-performance engines (race cars) | Ductile Iron (ASTM A536 Grade 65-40-18) ▲▲ (50% higher tensile strength) | Superior fatigue resistance; reduces breakage risk in high-G scenarios. | Requires specialized machining for installation. |

| Customizable Transparent Holder Rings | Maintenance/diagnostics for technicians | Acrylic Holder (ISO 1043) + embedded sensors ▲▲▲ (Real-time wear tracking) | Enables non-destructive inspection; alerts to carbon buildup or misalignment. | Complex design increases cost by 60%; limited to specific engine configurations. |

| Mack Heavy-Duty Cast Iron Rings | Mack E6/E7 series engines | Cast Iron (ASTM A48 Class 30B) ▲ (20% thicker than industry standard) | Optimized for Mack’s engine geometry; reduces oil consumption by 15%. | Exclusive to Mack models; incompatible with other brands. |

| Compact Design Piston Rings | Space-constrained engines (maritime) | Reduced profile (0.5mm thinner than standard) ▲ (Saves 12% cylinder space) | Enables smaller engine designs without sacrificing basic performance. | Load capacity drops by 25%; unsuitable for prolonged high-torque use. |

⭐⭐⭐⭐⭐ James Wilkins - Senior Diesel Technician, Long-Haul Trucking Fleet

"I've been working on Mack E6 engines for over 15 years, and the EPR1816 piston ring set is one of the best OEM-compatible upgrades I’ve used. The cast iron construction holds up under extreme heat, and we’ve seen a noticeable drop in oil consumption across our fleet. The transparent acrylic holder is a game-changer—we can do quick visual checks during routine maintenance without pulling the engine apart. Installed these in six trucks back in May 2024, and after 7 months of heavy hauling, zero failures."Purchase Date: May 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Daniel Reyes - Independent Truck Mechanic, Home Garage

"As someone who works on Mack engines in my off-hours, I needed a reliable, high-quality piston ring set that wouldn’t break the bank. The EPR-1816 delivered. Installation was straightforward thanks to the precise fit for 353GC241CP bore size, and the triple-ring design really does make a difference in compression. I love being able to inspect ring alignment through the clear holder—saved me hours of guesswork. Only reason I’m not giving 5 stars is because the Pro Model is a bit pricey, but it’s clear it’s built for serious duty."Purchase Date: February 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Lisa Chen - Maintenance Supervisor, Mining Equipment Facility

"We service heavy-duty Mack-powered machinery in extreme conditions—dust, heat, constant load. After switching to the Pro Model of the EPR1816 series last October, we’ve cut unscheduled engine downtime by nearly 30%. The 520°C temperature resistance and low-friction coating are exactly what we needed. The transparent holder allows our team to catch early signs of carbon buildup before it becomes a major issue. These rings have already outlasted the previous steel ones we were using by more than double."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Marcus Thompson - Fleet Operations Manager, Regional Hauling Company

"We manage a fleet of 42 Mack trucks, and engine reliability is non-negotiable. Since adopting the EPR1816 series across our maintenance schedule in January 2025, we’ve seen improved fuel efficiency and reduced oil top-offs—key indicators of proper ring sealing. The OEM-specific compatibility with both E6 and FCM engines means we can standardize parts across our garage. Our mechanics also appreciate the time saved with the visual inspection feature—no more disassembling engines just to check ring condition."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ Elena Rodriguez - Precision Engine Rebuilder

"I rebuild Mack E6 engines for specialty clients, and the customization options on this ring set are impressive. I ordered a batch with adjusted groove depth for a vintage 353GC280B rebuild, and the fit was flawless. The cast iron material machines beautifully and seats perfectly. The only caveat? The transparent holder, while innovative, requires careful handling during installation to avoid cracking. But once in place, it’s incredibly useful for post-rebuild diagnostics."Purchase Date: August 2024 | Usage Period: 5 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Tom Reynolds - ASE Master Technician & Engine Specialist

"For Mack E6 and FCM series engines, the EPR1816 piston ring set stands out for its thermal stability and OEM-level precision. The use of high-grade cast iron over steel is a smart choice—steel may seem stronger, but it doesn’t handle thermal cycling as well in sustained high-load environments. The transparent inspection holder is a diagnostic innovation that should become standard across the industry."

Diane Foster - Fleet Maintenance Optimization Consultant

"After evaluating over 20 piston ring products for fleet applications, I recommend the Pro Model of the EPR1816 series for any operation running Mack-powered trucks over 300,000 miles. The 20,000-hour wear resistance and 16% higher temperature tolerance translate directly into extended engine life and lower TCO (Total Cost of Ownership). The ability to perform non-invasive inspections reduces labor costs significantly."

Posted: 2 days ago

"Put these in my 2018 Mack with 450K miles. After 3 months, compression is stable, and no blue smoke at startup. The clear holder made it easy to verify seating. Outstanding product."

Posted: 1 week ago

"Running in a FCM-powered haul truck in the desert. 500+ hours and still performing like new. The cast iron doesn’t warp like the last set we used. Highly recommend the Pro Model."

Posted: 3 weeks ago

"Used the customizable version for a client’s rare Mack variant. Fit and finish were excellent. Slight delay in custom order shipping, but product quality made up for it."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.