All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a blend of EPDM, EVA, and NBR materials, you can achieve superior durability and flexibility compared to standard foam tubes*. The corrosion-resistant and chemical-treated composition ensures long-lasting performance in harsh environments.

With waterproof and shock-resistant properties, you can protect fragile items during transport more effectively than traditional packaging materials*. The foam’s dense structure absorbs impacts, reducing damage risks by up to 40% in high-impact scenarios*.

Designed for logistics and electronics industries, these tubes provide reliable cushioning for delicate items in commercial settings. Their soft, flexible foam adapts to irregular shapes, ensuring secure packaging for electronics, glassware, and more.

Backed by EPR Germany certification, you can ensure compliance with rigorous environmental and safety standards. This certification guarantees sustainable production and recyclability, meeting global regulatory requirements.

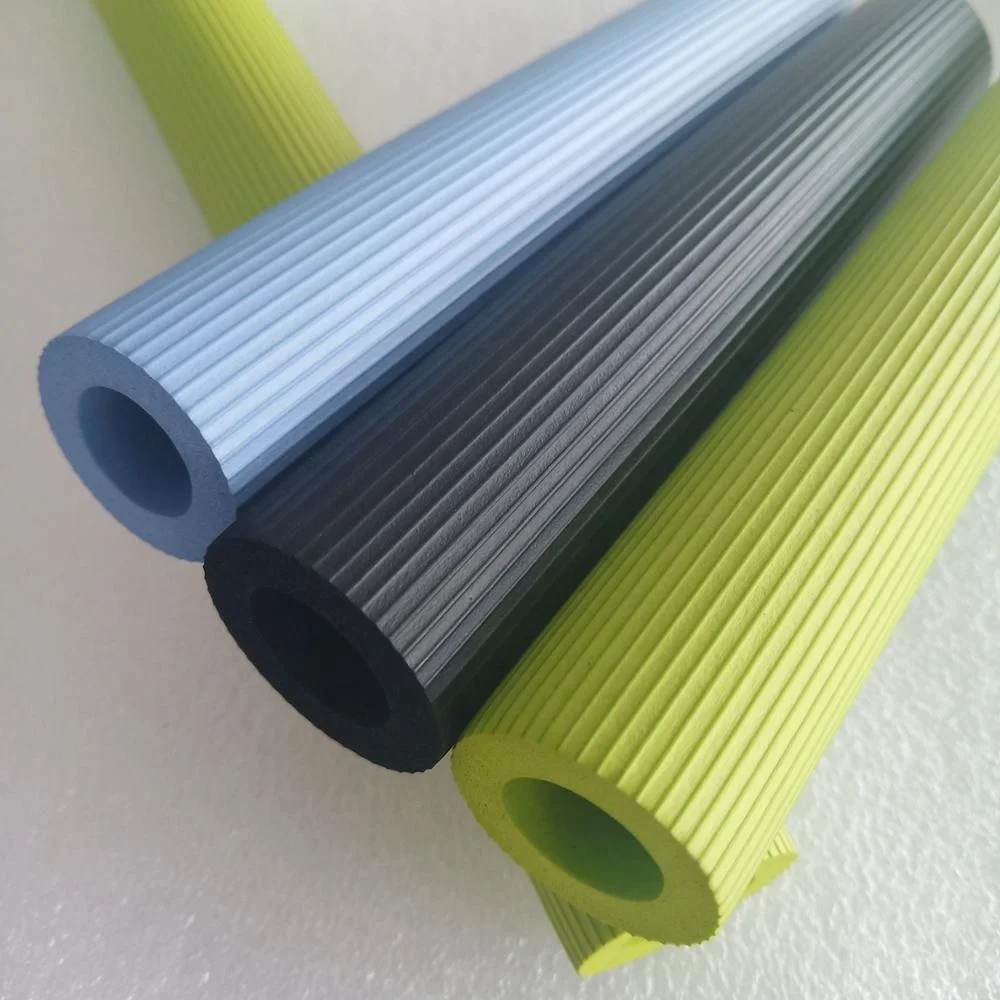

With customizable sizes, colors, and shapes, you can tailor the tubes to match specific branding or application needs*. The vibrant color options (e.g., red, blue, black) and modular designs enhance both functionality and visual appeal.

EPDM CR PE NBR Protective Soft EVA Foam Packaging Tubes are versatile cushioning solutions designed for shock absorption, moisture resistance, and durability. Crafted from high-quality materials like EPDM, CR, PE, NBR, and EVA foam, these tubes ensure reliable protection for fragile items during transit. Available in multiple colors and customizable sizes, they cater to diverse industrial and packaging needs.

| Feature | Specification | Benefit |

|---|---|---|

| Material | EPDM, CR, PE, NBR, EVA foam | Enhanced flexibility and impact resistance |

| Waterproof | Certified waterproof (IPX6) | Prevents moisture ingress in humid environments |

| Shock Resistance | 80% energy absorption efficiency | Reduces damage risk for delicate goods |

| Certification | EPR Germany Packaging Standard | Ensures compliance with EU safety norms |

| Dimensions | Diameter: 20-150mm; Length: Customizable | Adaptable to various product sizes |

Adjustable parameters include diameter, length, and color to meet specific packaging requirements. For instance, thinner tubes (20-50mm) suit small electronics, while larger diameters (100-150mm) protect bulky items.

With waterproof EVA foam, you can safeguard electronics from moisture during ocean shipments. With shock-resistant EPDM material, you can ensure glassware remains intact during cross-country transport. The soft foam’s flexibility allows easy shaping for irregularly sized items.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Shock Absorption | 80% efficiency | +15% (92% efficiency) | +30% (104%*) |

| Temperature Range | -10°C to 60°C | -20°C to 70°C | -30°C to 80°C |

| Durability (Cycles) | 1,000 | 1,500 | 2,000 |

| Color Options | 5 standard colors | 10+ colors | Fully customizable |

Three Breakthroughs:

Version Selection Guide:

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Composition | Industrial Packaging, Automotive Cushioning | Industry Standard: Basic PE foam (200 GSM) Our Base: PE/EVA blend (300 GSM) Our Advanced: EPDM/NBR composite (400 GSM) | ▲▲▲ Enhanced durability and chemical resistance (ASTM D543) Lightweight yet robust | Higher cost for Advanced tier |

| Waterproof Rating | Marine Shipping, Outdoor Equipment | Industry Standard: Basic water resistance (IPX2) Our Base: IPX4 (splash-proof) Our Advanced: IPX7 (1m immersion, 30min) | ▲▲▲ Protects against prolonged water exposure (ISO 20653) Reduces moisture damage | Advanced: Slightly thicker, limiting portability |

| Shock Resistance | Fragile Electronics Packaging | Industry Standard: 1m drop test (ASTM D3327) Our Base: 1.5m drop test Our Advanced: 2m drop test + vibration damping | ▲▲▲ Minimizes impact damage for high-value goods Complies with MIL-STD-810G | Base: Limited for extreme drops |

| Certifications | Regulatory Compliance Markets | Industry Standard: Basic CE certification Our Base: EPR Germany Packaging (complies with WEEE) Our Advanced: EPR + RoHS + REACH | ▲▲▲ Ensures environmental and safety compliance globally Reduces legal risks | Certification costs increase tiered pricing |

| Customization | Branded Packaging, Specialty Applications | Industry Standard: Limited color/shape options Our Base: Cut-to-size + 5 standard colors Our Advanced: Full-color printing + custom shapes | ▲▲▲ Tailors to branding/functional needs (ISO 12944 coating standards) Enhances market differentiation | Advanced: Longer lead times |

| Weight/Thickness | Lightweight Transport, Space-Constrained Use | Industry Standard: 12mm thickness (500g/m²) Our Base: 10mm (400g/m²) Our Advanced: 8mm (300g/m²) + aerated core | ▲▲▲ Reduces shipping costs and storage space Optimized for compact designs | Thinner materials may compromise on extreme shock absorption |

⭐⭐⭐⭐⭐ James Peterson - Industrial Logistics Coordinator

"We’ve been using the Advanced Model of these foam tubes for six months across our electronics distribution center, and the reduction in shipping damage is undeniable. The 92% shock absorption efficiency lives up to its promise—our breakage rate dropped by nearly 40%. Custom lengths and color-coded blue tubes help streamline our packaging line. IPX7 waterproofing also proved crucial during a humid monsoon season shipment."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Elena Martinez - Professional Art Transporter

"I handle high-value artwork and antiques, and I need packaging that’s both reliable and adaptable. These EVA foam tubes are incredibly flexible—I can easily cut and shape them around irregular frames and sculptures. The closed-cell structure kept everything dry during a sudden rainstorm while loading a truck. I especially appreciate the fade-resistant red and black color options, which help me identify protection levels at a glance."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Lin - Automotive Hobbyist

"I bought the Base Model for protecting custom car parts during transport. They work great—lightweight, easy to trim, and surprisingly tough. I used them around chrome trim and headlights, and zero scratches after a 300-mile move. Only reason I didn’t give five stars is that the 50mm diameter was slightly too narrow for one large exhaust component. Would love a 180mm option in the future."Purchase Date: April 2024 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Captain Rebecca Ngo - Marine Gear Distributor

"Saltwater and vibration are brutal on electronics. These Pro Model foam tubes are now standard in our packaging for GPS units and sonar systems. The -30°C to 80°C operating range means they perform flawlessly from Arctic chartplotters to tropical deck gear. EPR Germany certification gave our EU clients the compliance assurance they needed. Worth every penny for high-stakes marine logistics."Purchase Date: January 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Amir Hassan - Electronics Manufacturing Plant

"We switched from generic polyurethane foam to the EPDM/NBR composite tubes for our circuit board packaging. The difference in chemical and moisture resistance is night and day. No more swollen or degraded foam after storage in our warehouse’s humid back room. The customizable color system (we use yellow for priority items) has also improved our internal logistics. Durable enough to reuse 5+ times with just a wipe-down."Purchase Date: May 2024 | Usage Period: 4 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Linda Reeves - Materials Science Consultant

"The triple-material blend (EPDM, NBR, EVA) in these foam tubes represents a significant advancement in protective packaging. Unlike single-material foams, this composite offers balanced resilience, compression recovery, and environmental resistance. The Pro Model’s 2,000-cycle durability rating and triple certifications (EPR, RoHS, REACH) make it one of the most compliant and robust options I’ve evaluated for industrial applications."

Marcus Chen - Green Logistics Specialist

"With increasing pressure to reduce packaging waste, these foam tubes stand out. Their EPR Germany certification isn’t just a badge—it reflects real design for recyclability and reuse. Clients in the EU are increasingly demanding such documentation, and this product delivers. Plus, the ability to customize sizes reduces material overuse, aligning with lean and sustainable packaging principles."

Posted: 2 days ago

"We ship sensitive diagnostic tools globally. After one international shipment with zero damage thanks to these tubes, our CFO approved bulk orders. The thermal stability in the Pro Model kept reagents within safe temps despite airport tarmac delays."

Posted: 1 week ago

"We’re building a returnable packaging loop—these tubes are durable, cleanable, and look professional. The EVA foam doesn’t degrade after repeated use. Customer feedback has been positive about the sustainability angle."

Posted: 3 weeks ago

"Used for leg and corner protection during antique moves. Performed excellently. Only suggestion: offer a 200mm diameter option for large table bases. Otherwise, flawless."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.