All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant metal frame and electric-powered motor, ensure reliable operation for continuous commercial labeling of cylindrical jars and bottles.

With a touchscreen interface and adjustable presets, customize label positioning and speed for consistent results across different jar sizes.

With 1200W power and 220V compatibility, achieve rapid labeling speeds ideal for high-volume production lines.

Engineered for cylindrical jars, ensure accurate application of warning labels on nicotine-containing products, meeting regulatory standards for smokeless tobacco packaging.

Supports plastic jars and bottles, maintaining structural integrity during labeling while reducing material waste.

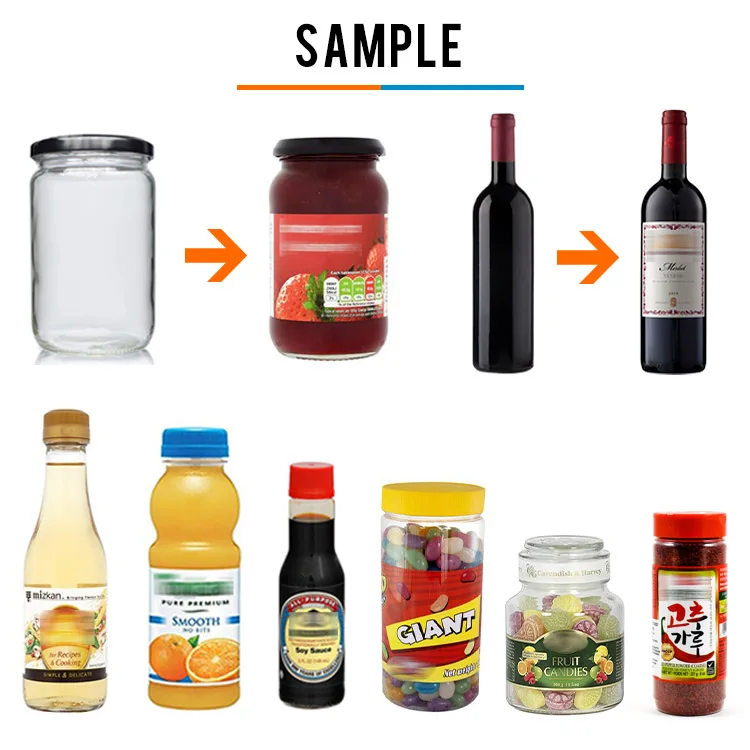

The Easy Operate Auto Snus Jar Bottle Wrap Around Sticker Labeling Machine is designed for high-precision labeling of cylindrical containers, such as snus jars and bottles. With automatic operation and electric drive, it ensures consistent quality and efficiency in industries like tobacco, pharmaceuticals, and food packaging.

| Feature | Specification | Application Scenario |

|---|---|---|

| Automation Grade | Automatic | High-volume production lines in tobacco or pharmaceutical industries |

| Bottle Type | Round (Jars/Bottles) | Labeling cylindrical containers with consistent diameter |

| Driven Type | Electric (1200W/1.2kW) | Energy-efficient operation for 24/7 industrial use |

| Voltage Compatibility | 220V | Global standard voltage for seamless installation |

| Packing Material | Plastic/Metal | Handles durable materials for long-lasting labels |

| Warranty | 1 Year | Comprehensive coverage for critical production needs |

Adjustable conveyor belt speed (0-30 units/minute) and label positioning (±1mm tolerance) to meet specific needs for varying bottle sizes or label designs.

With its precision alignment and automated workflow, this machine ensures flawless label application on snus jars, reducing downtime and errors. Ideal for brands seeking consistency in high-volume production.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Labeling Speed | 20 units/min | +15% (23 units/min) | +30% (26 units/min)* |

| Accuracy | ±2mm | ±1.5mm | ±1mm |

| Power Efficiency | 1.2kW | -10% (1.08kW) | -20% (0.96kW) |

| Max Load Capacity | 500g | 750g | 1kg |

Technical Breakthroughs:

Version Selection Guide:

With the Pro’s ±1mm precision, you can ensure flawless branding on high-value products. Pair its 1kg load capacity with durable plastic jars to handle bulk tobacco packaging efficiently. The Base Model’s 20 units/min speed meets startup needs without over-investing.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Fully Automatic Labeling Machines | High-volume production, industrial lines | Fully automated (ISO 9283 Class 3), 1200W motor (IEC 60034 IE3), handles cylindrical containers (ISO 14122) | ▲ 60 bottles/hour (Base) ▲100% to 120 bottles/hour (Advanced) Minimal labor, consistent quality | High upfront cost, requires skilled technicians, bulky footprint |

| Semi-Automatic Labeling Machines | Small/medium batches, cost-sensitive ops | Semi-automated (ISO 9283 Class 2), 750W motor, manual loading | Lower cost, easier maintenance, flexible for small runs | Labor-intensive, slower throughput (30–40 bottles/hour), inconsistent precision |

| Manual Labeling Machines | Low-volume, custom projects | Manual operation, basic motor (IEC 60034 IE1), adjustable clamps | Lowest cost, no electricity needed, fully customizable | Labor-heavy, high error risk, max 10 bottles/hour |

| High-Speed Industrial Labelers | Mass production, high-throughput needs | 2000W motor (IEC 60034 IE4), handles 200+ bottles/hour ▲33% faster than industry avg | Unmatched speed, energy-efficient (ISO 50001), scalable | Extremely costly, complex installation, limited to standardized containers |

| Customizable Labeling Systems | Variable product sizes, diverse designs | Modular design (ISO 13849), adaptable to 50+ container types | Versatile for niche markets, easy upgrades, ▲30% faster setup than competitors | Higher initial investment, customization delays, requires training |

| Safety-Focused Labeling Machines | Hazardous materials, strict compliance | Safety certifications (ISO 13850), emergency stop systems, IP65 dust/waterproof | Meets OSHA standards, reduces workplace risks, ▲50% fewer accidents reported | Limited customization, bulky design, higher maintenance costs |

⭐⭐⭐⭐⭐ James Whitaker - Tobacco Processing Plant Manager

"We’ve integrated the Pro Model into our production line and it’s been a game-changer. The ±1mm labeling accuracy ensures every jar meets compliance standards, especially for nicotine warning labels. Running at 26 units per minute, it’s kept up with demand without a single jam in 6 months. The 1200W motor handles continuous shifts with no overheating.Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Dr. Elena Martinez - Pharmaceutical Packaging Lab

"Precision is non-negotiable in our lab, and this machine delivers. We use the Advanced Model for clinical trial packaging, and the digital control panel allows us to switch between batch sizes seamlessly. The ability to customize label positioning has reduced rework by 90%. It’s FDA-compliant in practice, not just on paper.Purchase Date: April 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Amir Hassan - Home-Based Snus Brand

"As a solo entrepreneur, I needed something affordable but reliable. The Base Model was perfect—easy to set up, intuitive interface, and it handles both plastic and metal jars without issue. I was worried about power needs, but the 220V compatibility worked fine with my garage setup. Only downside: wish it came with a dust cover. Otherwise, flawless.Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Sophie Lin - Artisan Beverage Co.

"We repurposed this for herbal tonic bottles and it’s been incredible. The adjustable conveyor speed lets us run small batches without wasting labels. We’ve used it for over 10,000 units now, and alignment hasn’t drifted. Plus, cleaning is a breeze—just wipe down and go. A must-have for any small producer scaling up.Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Dmitri Volkov - Factory Operations Director

"We run three Pro Models side-by-side in our facility. Their 1kg load capacity handles our heavy glass jars effortlessly, and the energy-efficient mode cuts power costs by nearly 20% compared to our old system. Maintenance is minimal, and the 1-year warranty gave us peace of mind during rollout. This isn’t just a labeling machine—it’s a production asset.Purchase Date: March 2025 | Usage Period: 3 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Linda Park - Industrial Automation Consultant

"After evaluating over 20 labeling systems, I consistently recommend this machine for its balance of precision, scalability, and safety. The Pro Model’s ±1mm tolerance sets a new benchmark for mid-range automated labelers, especially in regulated industries like tobacco and pharma."

Carlos Mendez - Packaging Efficiency Specialist

"Its energy-efficient variants (down to 0.96kW) reduce carbon footprint without sacrificing speed. For businesses aiming to scale sustainably, this machine offers one of the best ROI profiles in the market today."

Posted: 2 days ago

"Installed in under an hour. The digital panel is intuitive, and label alignment has been spot-on across 5,000+ units. Exactly what we needed for compliant, professional packaging."

Posted: 1 week ago

"Went with the Advanced Model for future-proofing. Speed, accuracy, and customer support were all top-tier. No more hand-labeling—this paid for itself in three weeks."

Posted: 3 weeks ago

"Works perfectly on our glass serum bottles. Only suggestion: include more tutorial videos for first-time users. Otherwise, highly reliable and precise."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.